Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Product Code

- MITM16564

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Key Features

Macrolex® Black TP LXS 51151 stands out for such properties as:

- Deep black color

- High color strength

- Excellent heat stability in many important engineering thermoplastics: e. g. 340°C in PC and 280°C in ABS (for PS, PET, SAN, PMMA, PBT, see performance of MACROLEX® Black TP LXS 15151 below)

- High light fastness

- High weather fastness

- Product Benefits

- Piano-like black

- High gloss

- High solubility

- Outstandingly consistence and exact coloristics (dE ≤0.7)

- Cost efficient due to high color strength

- Halogen free

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Performance Details

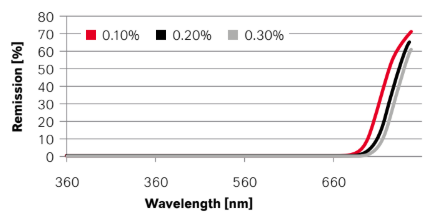

Remission curves of 0.10%, 0.20% and 0.30% TP LXS 51151 in PS (2mm thickness).

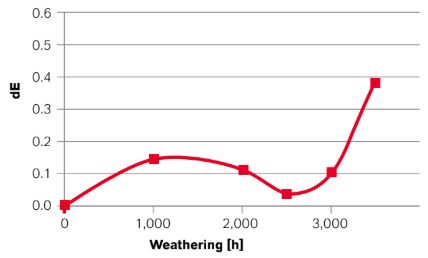

Weather fastness of 0.10% TP LXS 51151 in PC (2 mm thickness) according to DIN EN ISO 4892-2. The test period of 3500h equals approx. 2 years of weathering in Florida.

- Product Applications

Macrolex® Black TP LXS 51151 is the colorant of choice for applications where carbon black is too dull, influences the polymers’ properties too strongly or is too hard to process. The highly soluble high-performance dyestuff Macrolex® Black TP LXS 51151 provides superior results in that case. Furthermore, Macrolex® Black TP LXS 51151 helps contribute to the circular economy as it enhances the recyclability of black plastic parts. Due to difficult sorting, black plastics are often not recycled. As Macrolex® Black TP LXS 51151 does not interfere with the NIR-detection of plastics, sorting becomes possible. Ideal applications are plastic parts that require a piano-like black color, e.g., beverage bottles, electronic devices, and children’s toys. PET colored with Macrolex® Black TP LXS 51151 is suitable for contact with edibles. All of its ingredients are FDA compliant.

Properties

- Color (Properties)

Principal Information

- Group Principal Number

- S000008

- Principal

Other

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Shelf Life & Stability

Value Units Test Method / Conditions Light Fastness 6.0-7.0 - Blue Wool Scale (BWS) PC, reduction at 0.1%, 1/3 standard depth in reduction with 1% titanium dioxide Light Fastness 7.0-8.0 - Blue Wool Scale (BWS) PC, transparent at 0.05% dye, 1/3 standard depth in reduction with 1% titanium dioxide Light Fastness 6.0 - Blue Wool Scale (BWS) PMMA, reduction at 0.1%, 1/3 standard depth in reduction with 1% titanium dioxide Light Fastness 7.0-8.0 - Blue Wool Scale (BWS) PMMA, transparent at 0.05% dye, 1/3 standard depth in reduction with 1% titanium dioxide Light Fastness 6.0-7.0 - Blue Wool Scale (BWS) PS, reduction at 0.18%, 1/3 standard depth in reduction with 2% titanium dioxide Light Fastness 7.0 - Blue Wool Scale (BWS) PS, transparent at 0.05% dye, 1/3 standard depth in reduction with 2% titanium dioxide Light Fastness 6.0-7.0 - DIN EN ISO 4892-2 PC, reduction at 0.1%, 1/3 standard depth in reduction with 1% titanium dioxide Light Fastness 7.0-8.0 - DIN EN ISO 4892-2 PC, transparent at 0.05% dye, 1/3 standard depth in reduction with 1% titanium dioxide Light Fastness 6.0 - DIN EN ISO 4892-2 PMMA, reduction at 0.1%, 1/3 standard depth in reduction with 1% titanium dioxide Light Fastness 7.0-8.0 - DIN EN ISO 4892-2 PMMA, transparent at 0.05% dye, 1/3 standard depth in reduction with 1% titanium dioxide Light Fastness 6.0-7.0 - DIN EN ISO 4892-2 PS, reduction at 0.18%, 1/3 standard depth in reduction with 2% titanium dioxide Light Fastness 7.0 - DIN EN ISO 4892-2 PS, transparent at 0.05% dye, 1/3 standard depth in reduction with 2% titanium dioxide Shelf Life 0.0 - - Thermal Properties

Value Units Test Method / Conditions Thermal Resistance 280.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 1% titanium dioxide, PBT Thermal Resistance 340.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 1% titanium dioxide, PC Thermal Resistance 290.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 1% titanium dioxide, PET Thermal Resistance 300.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 1% titanium dioxide, PMMA Thermal Resistance 280.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 1% titanium dioxide, SAN Thermal Resistance 300.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 1% titanium dioxide, SB Thermal Resistance 300.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 2% titanium dioxide, PS Thermal Resistance 280.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 4% titanium dioxide, ABS