Enhanced TDS

Identification & Functionality

- Blend

- No

- CI Name

- CI Number

- Chemical Family

- Dye Type

- Function

- Dye

- Plastics & Elastomers Functions

- Product Code

- MITM14441

- Single Ingredient

- Yes

- Technologies

- Product Families

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Product Applications

Transparent and opaque dyeing of PS, SAN, PMMA, PC, PET, ABS and ABS / PC blends.

Properties

- Color (Properties)

- Physical Form

Technical Details & Test Data

- Technical Data

Fastness to Bleeding:

(Suitability for dyeing household utensils) No staining of distilled water, 2% by weight acetic acid, 10% by volume ethanol, coconut oil or peanut oil in our test on 0.1% dyeing of PS, ABS, SAN, PMMA, PC, PET and PVC-U. The tests were carried out in accordance with the recommendations of the German BfR [for plastic applications (saturated strips of filter paper, 5h at 50°C)].

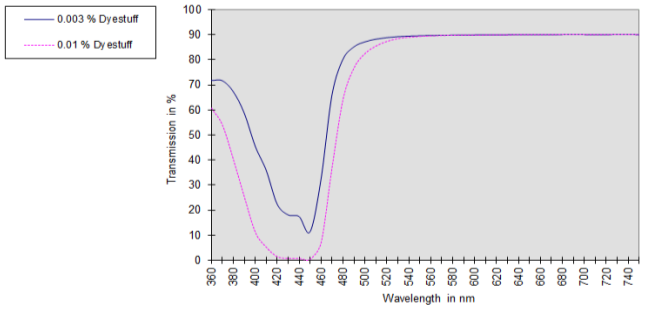

Transmission curve MACROLEX Yellow G Gran in GP-PS (2mm thickness)

Purity:

This dyestuff meets current purity requirements for dyeing household utensils and toys in Europe.

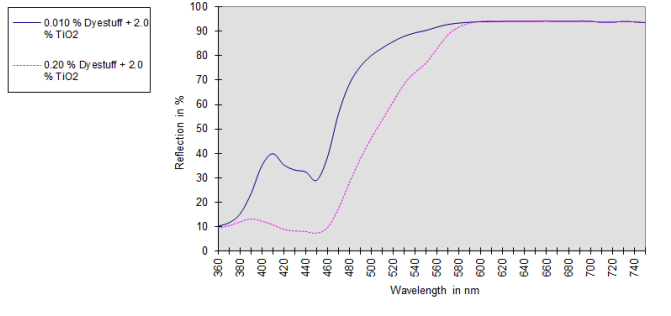

Reflection curve MACROLEX Yellow G Gran in GP-PS

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000008

- Principal

Other

- Appearance

- Neutral yellow microgranulate

- Appearance (SDS)

- Microgranules

- Color (SDS)

- Yellow

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Odorless

- Other Hazards

- None known

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions Dye Content 0.065 % % DIN EN ISO 4892-2 1/3 standard depth with 1% titanium dioxide (PS 2% titanium dioxide), transparent coloration with 0.05% dye; evaluated with 8-step blue wool scale, PMMA Dye Content 0.065 % % DIN EN ISO 4892-2 PC, 1/3 standard depth with 1% titanium dioxide (PS 2% titanium dioxide), transparent coloration with 0.05% dye; evaluated with 8-step blue wool scale Dye Content 0.12 % % DIN EN ISO 4892-2 PS, 1/3 standard depth with 1% titanium dioxide (PS 2% titanium dioxide), transparent coloration with 0.05% dye; evaluated with 8-step blue wool scale - Material Composition

Value Units Test Method / Conditions Acetone Content 0.5 g/L g/L At 23°C Benzyl Alcohol Content 2.0 g/L g/L At 23°C Ethanol Content 0.1 g/L g/L At 23°C - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.35 g/cm³ g/cm³ DIN EN ISO 787-11 Bulk Density approx. 0.53 g/cm³ g/cm³ DIN ISO 787-11 Density approx. 1.32 g/cm³ g/cm³ at 23°C Melting Point approx. 181.0 °C °C Solubility in Acetone approx. 10.0 g/L g/L at 23°C Solubility in Benzyl Alcohol approx. 5.0 g/L g/L at 23°C Solubility in Butyl Acetate approx. 8.0 g/L g/L at 23°C Solubility in Ethanol approx. 0.6 g/L g/L at 23°C Solubility in Methyl Methacrylate 1.0 g/L g/L At 23°C Solubility in Methyl Methacrylate approx. 7.0 g/L g/L at 23°C Solubility in Methylene Chloride 6.0 g/L g/L At 23°C Solubility in Methylene Chloride approx. 180.0 g/L g/L at 23°C Solubility in Styrene approx. 50.0 g/L g/L at 23°C Solubility in Xylene approx. 25.0 g/L g/L at 23°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Bulk Density (SDS) 530.0 - Density (SDS) 1.32 g/cm³ g/cm³ at 68°F Melting Point (SDS) 358.0 °F °F pH (SDS) 5.0-7.0 - - Shelf Life & Stability

Value Units Test Method / Conditions Light Fastness 8.0 - Blue Wool Scale (BWS) 1/3 standard depth, PC, 1% titanium dioxide, dye content 0.142%, transparent Light Fastness 8.0 - Blue Wool Scale (BWS) 1/3 standard depth, PC, 1% titanium dioxide, dye content 0.260%, transparent Light Fastness 8.0 - Blue Wool Scale (BWS) 1/3 standard depth, PC, 2% titanium dioxide, dye content 0.260%, transparent Light Fastness 8.0 - Blue Wool Scale (BWS) at 1/3 Standard depth, dye content 0.065%, PC, Transparent Light Fastness 8.0 - Blue Wool Scale (BWS) at 1/3 Standard depth, dye content 0.065%, PMMA, Transparent Light Fastness 7.0 - Blue Wool Scale (BWS) at 1/3 Standard depth, dye content 0.065%, with 1% titanium dioxide, PC, Reduction Light Fastness 7.0 - Blue Wool Scale (BWS) at 1/3 Standard depth, dye content 0.065%, with 1% titanium dioxide, PMMA, Reduction Light Fastness 6.0-7.0 - Blue Wool Scale (BWS) at 1/3 Standard depth, dye content 0.120%, with 1% titanium dioxide, PS, Reduction Light Fastness 8.0 - Blue Wool Scale (BWS) at 1/3 standard depth, dye content 0.12%, PS, transparent Light Fastness 7.0 - DIN EN ISO 4892-2 1/3 standard depth, PC, 1% titanium dioxide, dye content 0.142%, reduction Light Fastness 8.0 - DIN EN ISO 4892-2 1/3 standard depth, PC, 1% titanium dioxide, dye content 0.142%, transparent Light Fastness 6.0-7.0 - DIN EN ISO 4892-2 1/3 standard depth, PC, 1% titanium dioxide, dye content 0.260%, reduction Light Fastness 8.0 - DIN EN ISO 4892-2 1/3 standard depth, PC, 1% titanium dioxide, dye content 0.260%, transparent Light Fastness 6.0-7.0 - DIN EN ISO 4892-2 1/3 standard depth, PC, 2% titanium dioxide, dye content 0.260%, reduction Light Fastness 8.0 - DIN EN ISO 4892-2 1/3 standard depth, PC, 2% titanium dioxide, dye content 0.260%, transparent Light Fastness 8.0 - DIN EN ISO 4892-2 at 1/3 Standard depth, dye content 0.065%, PC, Transparent Light Fastness 8.0 - DIN EN ISO 4892-2 at 1/3 Standard depth, dye content 0.065%, PMMA, Transparent Light Fastness 7.0 - DIN EN ISO 4892-2 at 1/3 Standard depth, dye content 0.065%, with 1% titanium dioxide, PC, Reduction Light Fastness 7.0 - DIN EN ISO 4892-2 at 1/3 Standard depth, dye content 0.065%, with 1% titanium dioxide, PMMA, Reduction Light Fastness 6.0-7.0 - DIN EN ISO 4892-2 at 1/3 Standard depth, dye content 0.120%, with 1% titanium dioxide, PS, Reduction Light Fastness 8.0 - DIN EN ISO 4892-2 at 1/3 standard depth, dye content 0.12%, PS, transparent Shelf Life 60.0 - - Thermal Properties

Value Units Test Method / Conditions Thermal Resistance 280.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 1% titanium dioxide, PBT Thermal Resistance 340.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 1% titanium dioxide, PC Thermal Resistance 290.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 1% titanium dioxide, PET Thermal Resistance 300.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 1% titanium dioxide, PMMA Thermal Resistance 280.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 1% titanium dioxide, SAN Thermal Resistance 300.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 1% titanium dioxide, SB Thermal Resistance 300.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 2% titanium dioxide, PS Thermal Resistance 280.0 °C °C DIN EN 12877 at 1/3 Standard depth, with 4% titanium dioxide, ABS