Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Product Code

- MITM13538

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Benefits

Melt strength and foam density

Due to its ultra-high molecular weight and chemistry, Plastistrength® 580 process aid significantly improves the melt strength and rheological characteristics of cellular PVC formulations, which results in lower foam density.

Usage level

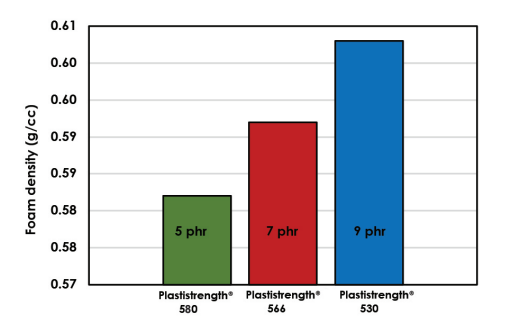

Plastistrength® 580 process aid offers excellent value in formulations by increased efficiency and dosage reduction compared to traditional PVC process aids. Figure 1 shows lower foam densities are achievable with lower loading levels for Plastistrength® 580 compared to other commercial products from Plastistrength® line of process aids.

Figure 1. Rigid PVC sheet foam density versus loading level.

Cell structure and surface finish

Use of Plastistrength® 580 process aid results in more uniform and finer cell structure after cell nucleation, compared to other commercially available process aids by capturing an optimum amount of gas evolved from the blowing agent component. Because of the additive’s tailored chemistry, a smooth surface finish is maintained after extrusion, allowing for exceptional weatherability and paintability

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Product Applications

Plastistrength® 580 process aid is recommended for all vinyl foam applications. The product’s excellent melt strength level makes it an ideal process aid for thick cellular PVC trim board and free foam applications. With improved efficiency versus competitive technologies, Plastistrength® 580 process aid can be used at reduced loading levels in deck boards, thin cellular PVC sheet, foam core pipe, and foamed moldings and maintain the needed final properties. Arkema’s Technical Service Team is available to discuss your application requirements, provide formulation guidance, and lab testing as needed.

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Appearance

- White powder

- Color (SDS)

- White

- Item Number

- Odor (SDS)

- Slightly acrylic

- Other Hazards

- Prolonged or repeated exposure may cause: headache, drowsiness, nausea, weakness, (severity of effects depends on extent of exposure).

- USA/DOT UN Number

- Not Applicable

- Physical Properties

Value Units Test Method / Conditions Bulk Density 0.5 g/cm³ g/cm³ Sieve Fractionation (Retained) 2.0 % % +40 Mesh Specific Gravity 1.11 - - Material Composition

Value Units Test Method / Conditions Volatile Content 1.0 %(W/W) %(W/W)