Enhanced TDS

Identification & Functionality

- Additives Included

- Function

- Activator

- Plastics & Elastomers Functions

- Product Code

- MITM09898

- Technologies

- Product Families

Features & Benefits

- Product Advantages

The CastReady product range is ideally suitable for direct mechanical processing on two-component (2K) machines.

- Ready-to-use dispersion of catalyst for the anionic polymerization of ε-Caprolactam

- Homogeneous solid mixtures with a long shelf life

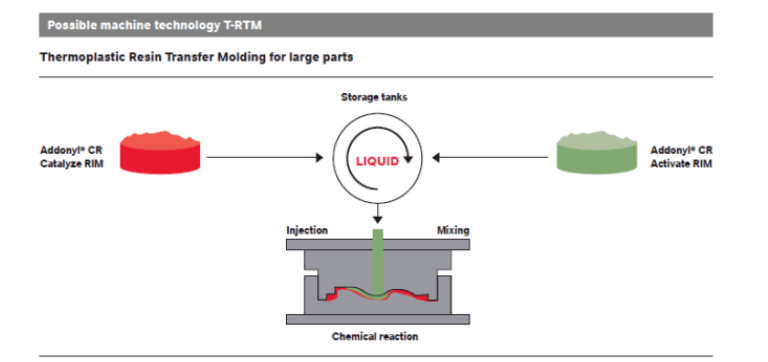

- Useable with different mashine technologies - RIM or T-RTM

- Short cycle life feasible - highly cost effective usage

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Product Uses

- The reactivity of the polymerizing melt is influenced by various factors (temperature of the melt and mold, moisture).

- We recommend an Addonyl® CR ACTIVATE concentration of at least 1:1 by weight with Addonyl® CR CATALYZE .

- The caprolactam melt containing the activator is susceptible to oxidation.

- Thus, we recommend working under inert gas.

Processing temperatures:

- Melt: 110 - 130 °C

- Mold: 130 - 160 °C

- Recommended Dosage: 1 part Addonyl® CR CATALYZE and 1 part Addonyl® CR ACTIVATE

Properties

- Physical Form

Technical Details & Test Data

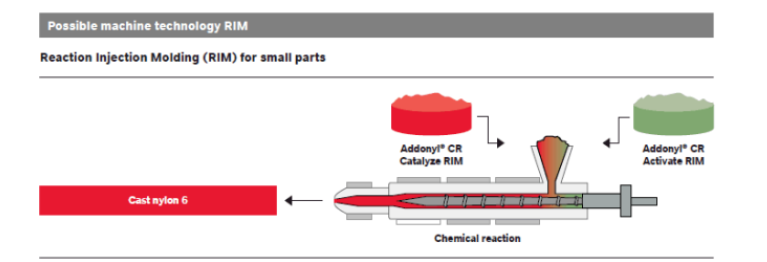

- Possible Machine Technology RIM

- Ideally suited for direct processing on two-component (2K) injection molding extruders

- Can be used with existing, only slightly adapted machines

3. Ideally suited for direct processing on two-component (2K) injection molding extruders

4. Can be used with existing, only slightly adapted machines

Safety & Health

- Safety Precautions

- A receiving inspection is recommended.

- The catalyst is strongly hygroscopic.

- Opened containers should be resealed tightly immediately after product has been removed.

- The product is highly corrosive.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000008

- Principal

Storage & Handling

- Storage Conditions

- The product has a shelf life of at least 12 months if handled correctly.

Other

- Appearance

- White flakes

- Item Number

- Odor

- Weak characteristic odor

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Physical Properties

Value Units Test Method / Conditions Moisture Content max. 0.03 % % - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 12.0 mo mo