Enhanced TDS

Identification & Functionality

- Chemical Family

- Function

- Impact Modifier

- Plastics & Elastomers Functions

- Product Code

- MITM10308

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Benefits

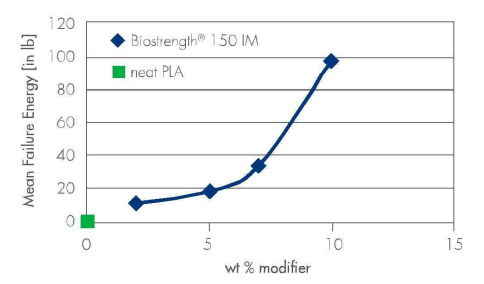

- Impact Improvement - Biostrength® 150 impact modifier is a high efficiency modifier that increases impact strength of PLA for use in sheet extrusion, calendering, injection molding and thermoforming

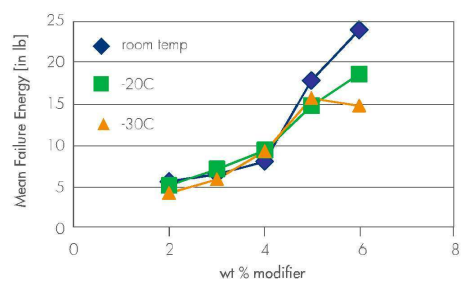

- Low temperature impact - Biostrength® 150 impact modifier retains high impact properties at low temperatures.

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Product Applications

Biostrength® 150 impact modifier is recommended for use in PLA for opaque applications or applications that do not require high transparency. Typical use levels range from 2% to 15% by weight. Blends of Biostrength® 150 impact modifier and PLA can be processed in the same equipment and under the same processing conditions recommended for PLA.

Properties

Technical Details & Test Data

- Gardner Impact and Haze

Gardner Impact 40 mil molded disk

Gardner Impact 20 mil molded disk

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Appearance

- White powder

- Color (SDS)

- White

- Dust Explosion Class (SDS)

- St1

- Dust Explosion Class (SDS)

- St1

- Item Number

- Odor (SDS)

- None

- Other Hazards

- Prolonged or repeated exposure may cause: headache, drowsiness, nausea, weakness, (severity of effects depends on extent of exposure).

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) 2.0-15.0 % % - Material Composition

Value Units Test Method / Conditions Volatile Content max. 1.0 % % - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.45 g/cm³ g/cm³ Sieve Fractionation (Retained) max. 2.0 % % +18 mesh Specific Gravity 1.0 - Storage Temperature max. 104.0 °F °F - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (SDS) approx. 1000.0 kg/m³ kg/m³ at 20°C Lower Explosion Limit (SDS) 20.0 g/m³ g/m³ Solubility In Water (SDS) max. 1.0 mg/L mg/L at 20°C Specific Gravity (SDS) 1000.0 - Water = 1, liquid - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d