Enhanced TDS

Identification & Functionality

- Chemical Family

- Function

- Impact Modifier

- Plastics & Elastomers Functions

- Product Code

- MITM13335

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Benefits

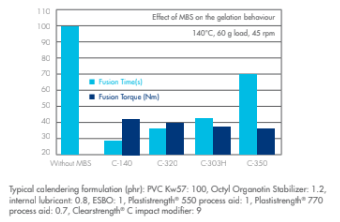

As part of Clearstrength® C series for transparent PVC film and sheets, Clearstrength® C-350 impact modifier offers the following benefits:

Fast fusion contributing to higher output productions

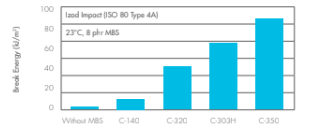

Impact efficiency allowing dosage optimization and cost saving in formulation

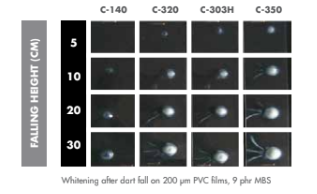

Optimum combination of clarity and impact strength satisfying the precise needs of customers

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Product Uses

- Clearstrength® 350 impact modifier is particularly recommended for use in rigid bottles as well as calendared films and extruded sheets when very high impact strength is required in addition to clarity.

- Clearstrength® 350 impact modifier is commonly used in PVC formulations for food. Dedicated information on regulatory status is available upon request.

- Recommended loading levels depend on impact requirement.

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Appearance

- White powder

- Color (SDS)

- White

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Slightly acrylic

- Other Hazards

- Processing may release vapors and/or fumes which cause eye, skin and respiratory tract irritation, The product, in the form supplied, is not anticipated to produce significant adverse human health effects. Contains high molecular weight polymer(s). Effects due to processing releases: Irritating to eyes, respiratory system and skin, Prolonged or repeated exposure may cause: headache, drowsiness, nausea, weakness, (severity of effects depends on extent of exposure), Handle in accordance with good industrial hygiene and safety practice. (powder) Mechanical irritation effects from dust exposure are possible at ambient temperature. This product may release fume and/or vapor of variable composition depending on processing time and temperature.

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Volatile Content max. 1.0 % % - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.39 g/cm³ g/cm³ Sieve Fractionation (Retained) max. 2.0 % % +18 mesh Specific Gravity 1.02 - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) 896.0 °F °F - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 730.0 -