Enhanced TDS

Identification & Functionality

- Chemical Family

- Country of Origin

- Function

- Impact Modifier

- Plastics & Elastomers Functions

- Product Code

- MITM10509

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Benefits

- Durastrength® 200 impact modifier has been extensively tested for long-term weather resistance, retaining excellent impact resistance and color. Similar weathering benefits are seen in translucent applications.

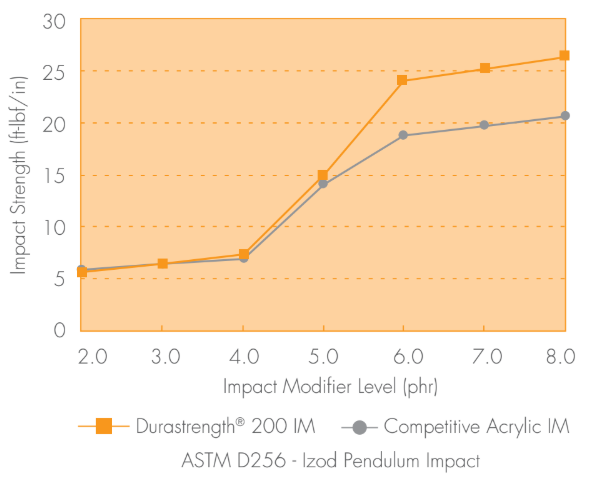

- The chemical composition of Durastrength® 200 impact modifier is well known for its excellent room-temperature and low-temperature impact resistance as measured by both the Izod and Gardner impact tests.

Izod Impact Testing (22°C)

.

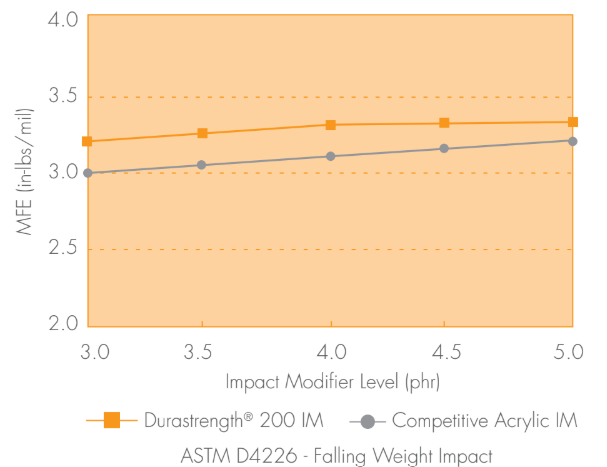

.Dart Drop Impact Resistance (22°C)

- Because of the low melt viscosity of Durastrength® 200 impact modifier, extrusion temperatures are lower, resulting in enhanced compound stability and output.

- Vinyl formulations employing Durastrength® 200 impact modifier exhibit reduced melt viscosity which helps to reduce extrusion pressures, prolonging screw and barrel life.

- The low melt viscosity of Durastrength® 200 impact modifier allows higher output without increasing extruder amps.

- The wide processing window of Durastrength® 200 impact modifier assures a consistently flawless surface finish.

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Product Uses

Durastrength® 200 impact modifier is recommended for applications such as vinyl siding, window profiles and fencing where good outdoor weathering and low-temperature impact resistance are critical properties. Durastrength® 200 impact modifier is also ideally suited for impact modification of pipe, conduit and injection molded goods. Its low melt viscosity and rapid fusion characteristics are ideal for custom injection molding applications. Use of Durastrength® 200 impact modifier in injection molding formulations imparts excellent flow and high gloss to finished products.

Durastrength® 200 impact modifier may be used in formulations serving many end-use applications, including some flexible PVC applications. Customers should evaluate Durastrength® 200 impact modifier in their own laboratories to establish optimum conditions for use in their processes and applications. Arkema’s Technical Service Team is available to diskuss your application requirements, provide formulation guidance and laboratory testing as needed.

Properties

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Appearance

- White Powder

- Color (SDS)

- White

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Acrylic - like

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Volatile Content max. 1.2 % % - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.48 g/cm³ g/cm³ Sieve Fractionation (Retained) max. 10.0 % % + 50 Mesh Specific Gravity 1.13 - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) 878.0 °F °F Bulk Density (SDS) 430.0-530.0 kg/m³ kg/m³ Decomposition Temperature (SDS) min. 482.0 °C °C Density (SDS) 1.13 g/cm³ g/cm³ Specific Gravity (SDS) 1.13 - water=1 - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 730.0 d d