Enhanced TDS

Identification & Functionality

- Chemical Family

- Function

- Impact Modifier

- Plastics & Elastomers Functions

- Product Code

- MITM15090

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Benefits

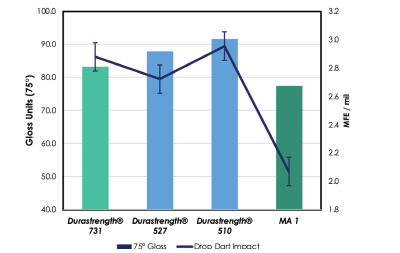

- Durastrength® 731 offers consistent low gloss performance compared to other acrylic impact modifier technology.

- Durastrength® 731 offers reduced gloss without compromising needed impact strength.

- Durastrength® 731 was developed specifically for rigid PVC applications using Arkema’s best-in-class acrylic high-rubber impact modifier technology.

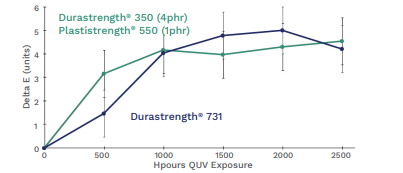

- Like all Durastrength® grades from Arkema, Durastrength® 731 is a proven, weatherable acrylic impact modifier for use in rigid PVC capstock and profile extrusions.

Gloss and Drop Dart Impact Performance of Extruded PVC Sheet

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Product Application

Durastrength® 731 low gloss impact modifier is recommended for use in tin and mixed-metal stabilized rigid vinyl formulations where reduced surface gloss is preferred for the final weatherable application. As with all impact modifiers for rigid vinyl applications, proper formulation is required to develop the proper balance of shear and mixing during extrusion to maximize impact properties. Durastrength® 731 is ideally suited for vinyl siding capstock, low gloss rigid profile including window, fence, deck and rail applications.

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Color (SDS)

- White

- Insoluble in (SDS)

- Water

- Item Number

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Volatile Organic Compounds (VOC) max. 1.2 % % - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.45 g/cm³ g/cm³ Sieve Fractionation (Through) 15.0 % % 50 Mesh - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) 878.0 °F °F Bulk Density (SDS) 110.0 g/cm³ g/cm³ - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d