Enhanced TDS

Identification & Functionality

- Chemical Family

- Fluids & Lubricants Functions

- Product Code

- MITM15725

- Technologies

- Product Families

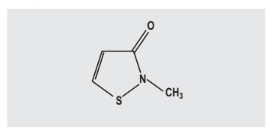

- Chemical Structure

Structure:

Features & Benefits

- Fluids & Lubricants Features

- Labeling Claims

- Key Features

Broad Spectrum Efficacy (including Mycobacteria):

- KORDEK™ LX5000 Biocide is efficacious against gram-positive and gram-negative bacteria, mold, and yeast. Laboratory studies have also shown good efficacy versus natural populations of mycobacteria present in contaminated fluid samples from the field (laboratory-dosed biocide testing).

Formaldehyde-free:

- KORDEK™ LX5000 Biocide contains NO FORMALDEHYDE and is not a formaldehyde releaser. It is also halogen (chlorine) free, nitrate-free, metal-free (no hardness salts), and contains no organic solvents or volatile organic compounds (VOC).

Formulation in Metalworking Fluid Concentrates:

- DuPont has developed novel, stabilization technology which enables the effective use of KORDEK™ LX5000 Biocide in various concentrate formulations.

Compatibility:

- KORDEK™ LX5000 Biocide is chemically compatible with most metalworking fluid concentrate components in end-use fluids. Formulated in water, it can be used in most concentrates (soluble oils, semi-synthetics, and true synthetics) and is compatible with KATHON™ 893MW Fungicide and many other commercially available biocides.

Enhanced Stability for Long-term Preservation:

- The active ingredient in KORDEK™ LX5000 Biocide provides excellent stability in dilute fluids at pH 10 and below and provides long-term microbial efficacy.

- Product Performance

- Excellent microbial control has been achieved for 4 to 6 months with concentrate dosing only.

- Bacterial control achieved at 100-200 ppm KORDEK™ LX5000 Biocide for total bacteria and SRB's (<103/mL).

- Fungal control (<10/mL) achieved at 200-300 ppm KORDEK™ LX5000 biocide.

- Excellent system operating performance (pH, alkalinity, tramp oil, rust control, tool life).

- Improved control over emulsion stability.

- No odor or worker complaints.

- Machine operators very satisfied.

Applications & Uses

- Application Method

- Fluids & Lubricants End Use

- Fluids & Lubricants Type

- Markets

- Applications

- Product Uses

Metalworking Fluid Preservation – Tankside Addition:

- KORDEK™ LX5000 Biocide is recommended for the control of bacteria and fungi in water-extendible metalworking fluids (soluble oil, semi-synthetic and synthetic types). The preservative should be dispensed as a tankside additive into the circulating use-dilution of the metalworking fluid using a metering pump or by manual pouring, and uniformly dispersed throughout the system.

Dosing:

- Use KORDEK™ LX5000 Biocide at 1.0 to 2.0 pints (12 to 24 lb) per 1,000 gallons of metalworking fluid every 1-6 weeks. This will provide 150-300 ppm product and 75 to 150 ppm active ingredient.

- The frequency of treatment may vary depending upon the rate of dilution of the preservative with makeup fluid, the nature and severity of contamination, level of control required, filtration effectiveness and system design.

Metalworking Fluid Concentrates:

- KORDEK™ LX5000 biocide is recommended for the control of bacteria and fungi in water-extendible metalworking fluids (soluble oil, semi-synthetic and synthetic types) when added to the metalworking fluid concentrates. KORDEK™ LX5000 Biocide should be added to the concentrate at a level to ensure that the final use-dilution metalworking fluid will contain 150-300 ppm KORDEK™ LX5000 Biocide (75 to 150 ppm active ingredient). Refer to the below listed table for dosing details.

Note:

- Regardless of the manner of incorporation, the total active ingredient level in the system should at no time exceed 150 ppm active ingredient in the final use dilution.

Dilution of Metalworking Fluid Concentrates

Dose Level Lbs. KORDEK™ LX5000 Biocide Per 100 Gal. Conc Quarts KORDEK™ LX5000 Biocide Per 100 Gal. Conc

15:1 Minimum 1.8 lb 3/4 Quarts 15:1 Maximum 3.6 lb 11/2 Quarts 20:1 Minimum 2.4 lb 1 Quart 20:1 Maximum 4.8 lb 2 Quarts 25:1 Minimum 3.0 lb 1 1/4 Quarts 25:1 Maximum 6.0 lb 2 1/2 Quarts

Properties

- Physical Form

- Soluble In

Regulatory & Compliance

- Certifications & Compliance

- Contains any chemicals listed on Prop 65 (including impurities, residues, catalysts, monomers, and by-products and excluding heavy metals)?

Technical Details & Test Data

- Technical Data

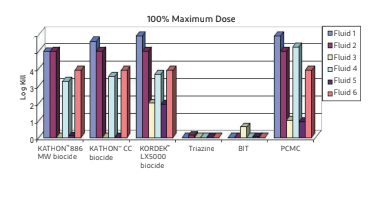

Biocide Efficacy vs Mycobacteria at Maximum Dose Rates:

- KORDEK™ LX5000 Biocide (methylisothiazolone) was the only biocide that provided at least a 90% kill (1-log reduction) in all 6 fluids.

- PCMC showed good kill (>99.9%) in 4 fluids, but only a 90% kill in one other fluid.

- KATHON™ 886 MW and KATHON™ CC Biocides showed a >99.9% kill (3-log reduction) in 4 fluids, but showed no kill in two fluids.

- The triazine and BIT failed to achieve a 1-log kill in any of the 6 fluids.

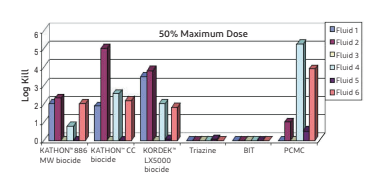

Biocide Efficacy vs Mycobacteria at 50% Maximum Dose Rates:

- KORDEK™ LX5000 and KATHON™ CC Biocides achieved at least a 90% kill (1-log reduction) in 4 fluids but no kill in the other 2 fluids.

- The chlorophenol, PCMC, showed good kill (>99.9%) in 2 fluids, but less than 90% kill in the other 4 fluids.

- KATHON™ 886 MW Biocide showed a 90-99% kill in 3 fluids, but no kill in the other 3 fluids.

- The triazine and BIT failed to achieve a 1-log kill in any of the 6 fluids tested.

- Technical Details

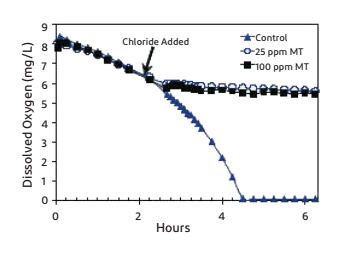

KORDEK™ LX5000 Biocide Functionality:

- Within minutes after addition of KORDEK™ LX5000 Biocide to a fluid, the metabolic activity of the microorganisms in the system shuts down. This includes cellular respiration (oxygen uptake; see graph), growth, energy generation, and nutrient uptake. The microorganisms, although still alive, are no longer able to reproduce or metabolize. After 24 to 48 hours of contact with a lethal dose of the methylisothiazolone (MIT) microbicide, most of the microorganisms have been killed.

KORDEK™ LX5000 Biocide is extremely stable in use diluted fluids and provides long term microbial control. Variables such as the degree of contamination/fouling and system dynamics can affect the life of the microbicide in a system.

- Efficacy Test Data

6-Week Use-Dilution Multiple Challenge Efficacy Tests:

Results with KORDEK™ LX5000 + KATHON™ 893MW Biocides:

Treatment Level Fluids Preserved vs: Bacteria and Fungi

50 ppm KORDEK™ LX5000 biocide + 67 ppm KATHON™ 893MW biocide 5 of 9 100-150 ppm KORDEK™ LX5000 biocide + 67-110 ppm KATHON™ 893MW biocide 9 of 9 Results with KORDEK™ LX5000 Biocide Alone:

Treatment Level # of Fluids Preserved

50 ppm 150-300 ppm 5 of 10 vs Bacteria 10 of 10 vs Bacteria

150 ppm 200-300 ppm 1 of 10 vs Fungi 10 of 10 vs Fungi

Safety & Health

- Safety Information

- KORDEK™ LX5000 Biocide must be handled using proper safety procedures. As supplied, KORDEK™ LX5000 Biocide is corrosive to skin/eyes and is a potential sensitizer. Should avoid any direct contact with KORDEK™ LX5000 biocide as supplied.

- After the shipping containers of KORDEK™ LX5000 Biocide have been emptied, they may still contain considerable amounts of concentrated preservative.

- To minimize the effect of accidental exposure, the containers should be rinsed at least three times with water before they are discarded.

- The best way to handle the rinse water (and the biocide it contains) is to charge it to the product to be preserved; otherwise, the rinse liquids and empty containers should be disposed of as specified by local regulations.

- It is recommended that any unused amounts of the preservative be deactivated prior to disposal.

Spill Cleanup Procedures:

- Spills should be absorbed with spill pillows or spongy inert solid materials such as vermiculite; the contaminated absorbent should then be transferred to closed containers and disposed of in accordance with local regulations.

- After the supernatant biocide has been removed by absorption, the affected spill area should then be chemically decontaminated. In such cases, an aqueous solution of 5% sodium bicarbonate and 5% sodium hypochlorite should be applied to the site of the spill to deactivate the remaining KORDEK™ LX5000 biocide.

- The general rule is to apply 10 times the volume of deactivating solution for each estimated volume of residual KORDEK™ LX5000 biocide. After the deactivating solution has been applied, it should be allowed to stand for 30 minutes.

- The spill site should then be flushed with copious amounts of water. The aqueous residue from this flushing process should then be drained into a chemical sewer.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000008

- Principal

Other

- Appearance

- Clear colorless to amber liquid

- Appearance (SDS)

- Liquid

- Color (SDS)

- Clear colorless to brown

- IATA/ICAO Proper Shipping Name

- Corrosive liquid, toxic, N.O.S. (2-methyl-2H-isothiazol-3-one)

- IATA/ICAO UN Number

- UN2922

- IMO/IMDG EmS Fire

- F-A

- IMO/IMDG EmS Spill

- S-B

- IMO/IMDG Proper Shipping Name

- Corrosive liquid, toxic, N.O.S. (2-methyl-2H-isothiazol-3-one)

- IMO/IMDG UN Number

- UN2922

- Item Number

- Odor

- Mild

- Other Hazards

- None known

- TDG Canada Proper Shipping Name

- Corrosive liquid, toxic, N.O.S. (2-methyl-2H-isothiazol-3-one)

- TDG Canada UN Number

- UN2922

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 3.0-7.0 - as is solution - Physical Properties

Value Units Test Method / Conditions Specific Gravity 1.2 - - Material Composition

Value Units Test Method / Conditions Active Content 50.0 % Methylisothiazolone - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 212.0 °F Density (SDS) 1.2 g/cm³ at 68°F Log Partition Coefficient (Log Pow) (SDS) -0.486 - at 24°C, n-octanol/water, Log pow Melting Point (SDS) 5.0 °F Molecular Weight (SDS) 115.15 g/mol Relative Density (SDS) 1.2 - pH (SDS) 3.0-5.0 -