Enhanced TDS

Identification & Functionality

- Additives Included

- Blend

- Yes

- Chemical Family

- Country of Origin

- Polymer Name

- Product Code

- MITM01781

- Single Ingredient

- No

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Processing Information

- Injection Molding

- Film Extrusion

- Profile Extrusion

- Extrusion

- Transfer Molding

- Casting

- Thermoforming

- Product Applications

- Athletic foot wear components

- Ski shoes

- Processing Information

- Typical melt temperature (Min / Recommended / Max) : 200°C / 240°C / 270°C.

- Typical mold temperature : 25 – 60°C.

- Drying time and temperature (only necessary for bags opened for more than two hours) : 4-6 hours at 65-75°C.

Properties

Technical Details & Test Data

- Technical Data

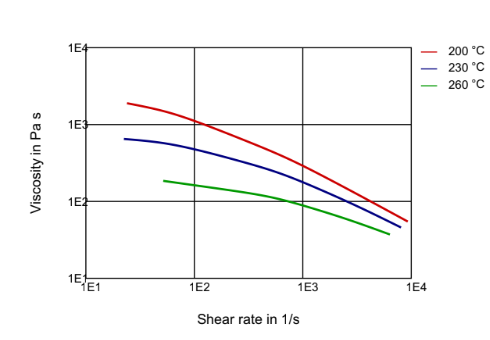

Viscosity-shear Rate

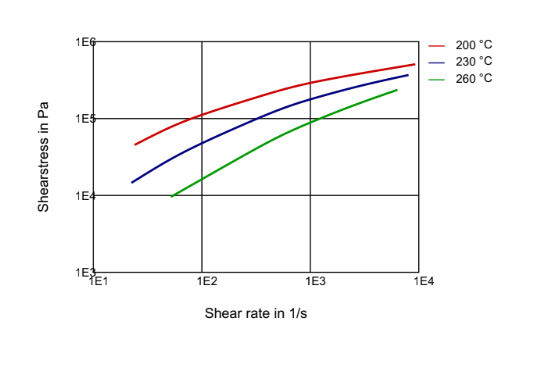

Shearstress-shear Rate

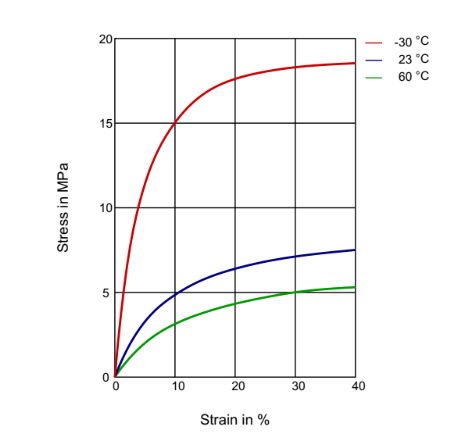

Stress-strain

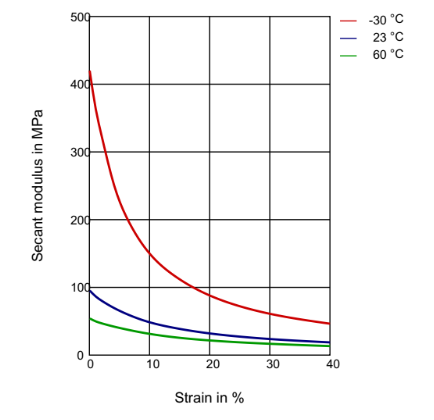

Secant Modulus-strain

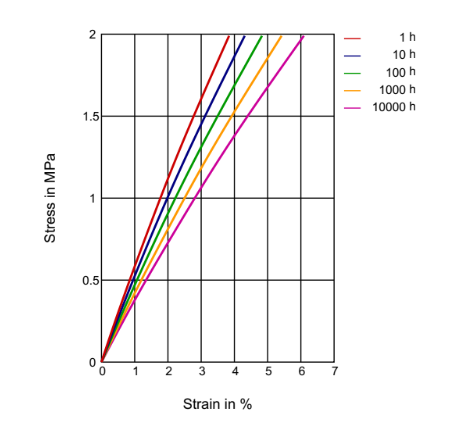

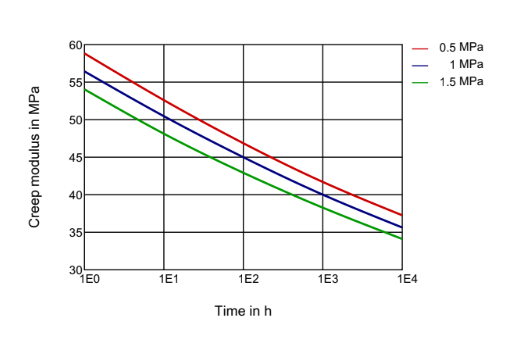

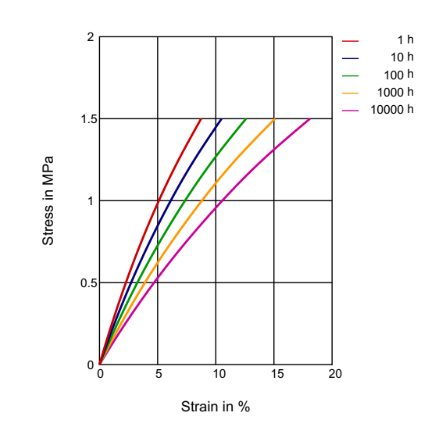

Stress - Strain (Isochronous) 23°C

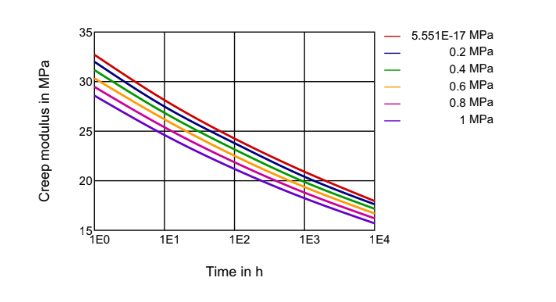

Creep Modulus - Time 23°C

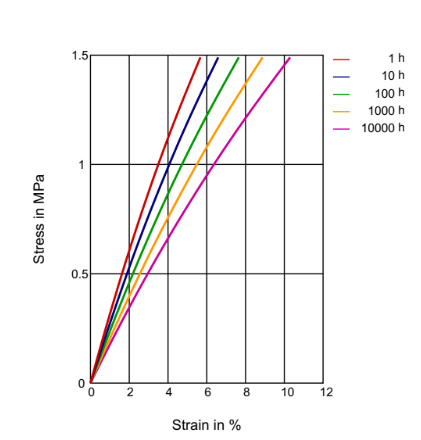

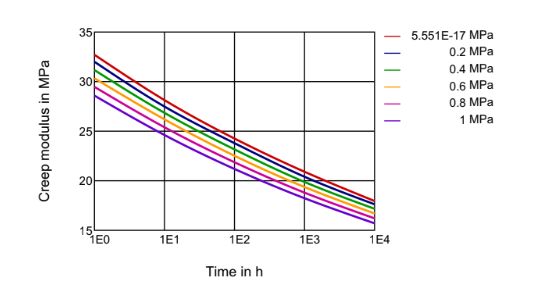

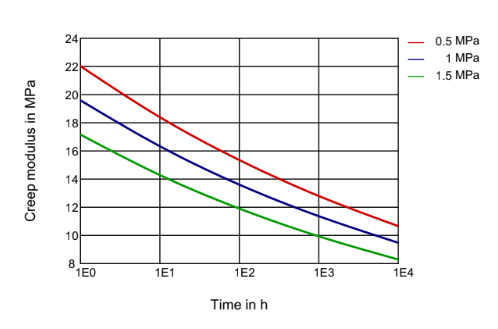

Stress - Strain (Isochronous) 60°C

Creep Modulus - Time 60°C

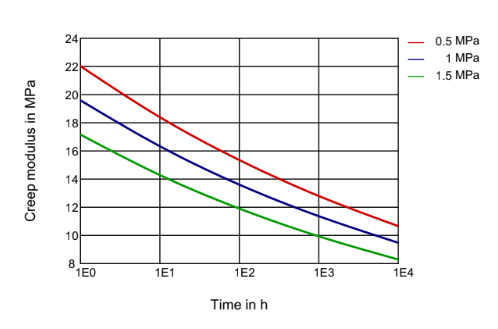

Stress - Strain (Isochronous) 80°C

Creep Modulus - Time 80°C

Stress - Strain (Isochronous) 100°C

Creep Modulus-Time 100°C

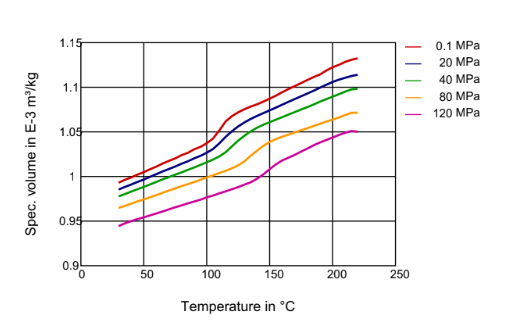

Specific Volume - Temperature (PVT)

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Color (SDS)

- Colorless to slightly yellow

- Item Number

- Odor (SDS)

- Odorless

- Other Hazards

- Processing may release vapors and/or fumes which cause eye, skin and respiratory tract irritation, The product, in the form supplied, is not anticipated to produce significant adverse human health effects. Contains high molecular weight polymer(s). Effects due to processing releases: Irritating to eyes, respiratory system and skin, Prolonged or repeated exposure may cause: headache, drowsiness, nausea, weakness, (severity of effects depends on extent of exposure).

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Electrical Properties

Value Units Test Method / Conditions Comparative Tracking Index 600.0 - IEC 60112 condensed Dielectric Constant 9.0 - IEC 60250 at 100 Hz, dry Dielectric Constant 5.0 - IEC 60250 at 1MHz, dry Dielectric Strength 38.5 kV/mm kV/mm IEC 60243-1 dry basis Dissipation Factor 0.111 tan δ tan δ IEC 60250 100Hz, dry Dissipation Factor 0.102 tan δ tan δ IEC 60250 1MHz, dry Surface Resistance 3000000000000.0 Ω Ω IEC 60093 condensed Volume Resistivity 320000000000.0 Ω-cm Ω-cm IEC 60093 dry basis - Mechanical Properties

Value Units Test Method / Conditions Hardness 50.0 Shore A Shore A ISO 868 Nominal Strain at Break min. 50.0 % % ISO 527-1 dry, at break, nominal Nominal Strain at Break min. 50.0 % % ISO 527-2 condensed, nominal Strain at Yield 25.0 % % ISO 527-1 dry basis Strain at Yield 25.0 % % ISO 527-2 condensed Strain at Yield 25.0 % % ISO 527-2 dry basis Stress at Yield 12.0 MPa MPa ISO 527-1 dry, at yield Stress at Yield 12.0 MPa MPa ISO 527-2 condensed, at yield Tensile Modulus 170.0 MPa MPa ISO 527-1 dry basis Tensile Modulus 165.0 MPa MPa ISO 527-2 condensed - Physical Properties

Value Units Test Method / Conditions Density 830.0 kg/m³ kg/m³ dry, liquid Density 1010.0 kg/m³ kg/m³ ISO 1183 condensed Density 1010.0 kg/m³ kg/m³ ISO 1183 dry basis Humidity Absorption 0.6 % % ISO 62 dry basis Load/Unload Temperature 66.0 °C °C ISO 75-1 at 0.45 MPa, dry, deflection under load Melting Point 159.0 °C °C ISO 11357-1 at 10°C/min Mold Shrinkage 1.4 % % ISO 2577 normal, dry Mold Shrinkage 1.2 % % ISO 2577 parallel, dry Mold Shrinkage 1.4 % % ISO 294-4 normal, dry Mold Shrinkage 1.2 % % ISO 294-4 parallel, dry Softening Point 142.0 °C °C ISO 306 at 50°C/h, 50N, dry Storage Temperature max. 140.0 °F °F Water Absorption 1.2 % % ISO 62 dry basis - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Decomposition Temperature (SDS) 572.0-662.0 °F °F - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 2.0 yr yr - Thermal Properties

Value Units Test Method / Conditions Coefficient of Thermal Expansion 0.00017 /K /K ISO 11359-1 dry, parallel Specific Heat 2800.0 J/kg.K J/kg.K dry, of melt Thermal Conductivity 0.18 W/m·K W/m·K