Enhanced TDS

Identification & Functionality

- Additives Included

- Blend

- Yes

- Chemical Family

- Polymer Name

- Product Code

- MITM16541

- Single Ingredient

- No

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Processing Information

- Typical melt temperature (Min / Recommended / Max) - Injection Molding: 210°C / 240°C / 270°C (410°F / 430°F / 520°F)

- Typical mold temperature - Injection molding: 10 - 30°C (50 - 90°F)

- Drying time and temperature: 60 - 70°C (140 - 160°F) / 4 - 8 hours

- Technical Data

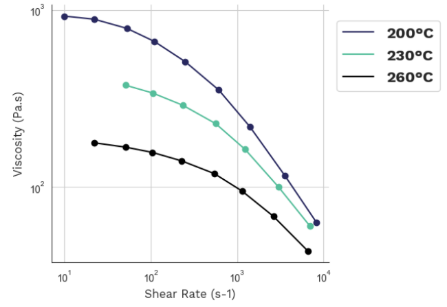

VIscosity-shear rate Pebax@ 4533 SP 01

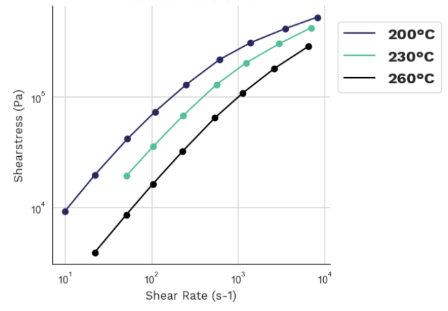

Shear stress-shear rate Pebax@ 4533 SP 01

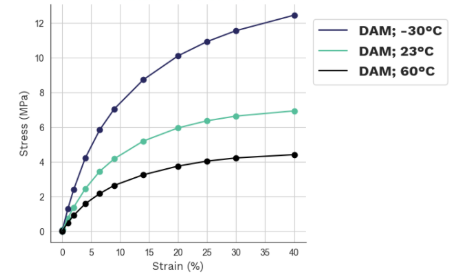

Shear stress Pebax@ 4533 SP 01

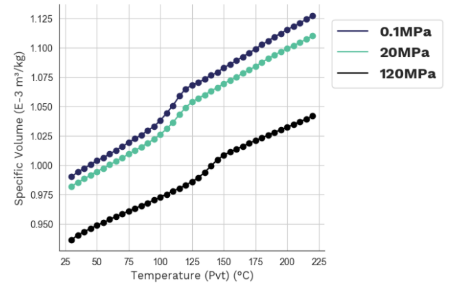

Specific volume-temperature (pvT) Pebax@ 4533 SP 01

Properties

- Physical Form

Principal Information

- Group Principal Number

- S000003

- Principal

Storage & Handling

- Storage Information

Two years from the date of delivery, when stored properly (sealed bags, appropriate moisture, UV protection and temperature).

Other

- Color (SDS)

- Colorless

- Insoluble in (SDS)

- Water

- Odor (SDS)

- Odorless

- Other Hazards

- Handle in accordance with good industrial hygiene and safety practice. (pellets/granules) This product may release fume and/or vapor of variable composition depending on processing time and temperature.

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Electrical Properties

Value Units Test Method / Conditions Comparative Tracking Index 600.0 - IEC 60112 at 23°C, conditioned Dielectric Constant 9.0 - at 100Hz, conditioned Dielectric Constant 6.0 - at 1MHz, conditioned Dielectric Constant 43.0 - IEC 60243-1 at 23°C, conditioned Dissipation Factor 2090.0 tan δ tan δ at 100Hz, conditionned Dissipation Factor 2090.0 tan δ tan δ at 1Mhz, conditionned Surface Resistivity 3000000000000.0 Ω/sq Ω/sq IEC 62631-3-2 at 23°C, conditioned Volume Resistivity 160000000000.0 Ω-m Ω-m IEC 62631-3-1 at 23°C, conditioned, transversal - Mechanical Properties

Value Units Test Method / Conditions Compression Set 37.0 % % ISO 815 dry basis Flexural Modulus 86.0 MPa MPa ISO 178 at 23°C, conditioned Hardness 90.0 Shore A Shore A ISO 868 at 15s, conditioned Nominal Strain at Break min. 550.0 % % ISO 527-1 at 23°C, 50 mm/min, 10°C/min, conditioned Nominal Strain at Break min. 550.0 % % ISO 527-1 at 23°C, 50 mm/min, 10°C/min, dry Nominal Strain at Break min. 550.0 % % ISO 527-2 at 23°C, 50 mm/min, 10°C/min, conditioned Nominal Strain at Break min. 550.0 % % ISO 527-2 at 23°C, 50 mm/min, 10°C/min, dry Stress 9.0 MPa MPa ISO 527-1 at 23°C, 50 mm/min, conditioned 50% strain Stress 9.0 MPa MPa ISO 527-1 at 23°C, 50 mm/min, dry, 50% strain Stress 9.0 MPa MPa ISO 527-2 at 23°C, 50 mm/min, conditioned 50% strain Stress 9.0 MPa MPa ISO 527-2 at 23°C, 50 mm/min, dry, 50% strain Stress at Break 42.0 MPa MPa ISO 527-1 at 23°C, 50 mm/min, conditioned Stress at Break 42.0 MPa MPa ISO 527-2 at 23°C, 50 mm/min, conditioned Tensile Modulus 81.0 MPa MPa ISO 527-1 at 23°C, 1 mm/min, conditioned Tensile Modulus 88.0 MPa MPa ISO 527-1 at 23°C, 1 mm/min, dry Tensile Modulus 81.0 MPa MPa ISO 527-2 at 23°C, 1 mm/min, conditioned Tensile Modulus 88.0 MPa MPa ISO 527-2 at 23°C, 1 mm/min, dry - Physical Properties

Value Units Test Method / Conditions Glass Transition Temperature (Tg) -55.0 °C °C ISO 11357-1 at 10°C/min Melting Point 147.0 °C °C ISO 11357-1 at 10°C/min Shrinkage 1.1 % % ISO 294-4 Normal (t+24h) Shrinkage 0.6 % % ISO 294-4 Parallel (t+24h) Specific Gravity 1.01 - ISO 1183-1 at 23°C Storage Temperature max. 140.0 °F °F Water Absorption 0.4 % % ISO 62 at 23°C, 50%HR, equilibrium Water Absorption 1.2 % % ISO 62 at 23°C, immersion, equilibrium - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) 698.0-842.0 °F °F ASTM D1929 Bulk Density (SDS) 550.0-650.0 kg/m³ kg/m³ Decomposition Temperature (SDS) 572.0-842.0 °F °F - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 2.0 yr yr - Thermal Properties

Value Units Test Method / Conditions Heat Deflection Temperature 52.0 °C °C ISO 75-1 at 0.45 MPa