Enhanced TDS

Identification & Functionality

- Chemical Family

- Country of Origin

- Plastics & Elastomers Functions

- Product Code

- MITM13433

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Benefits

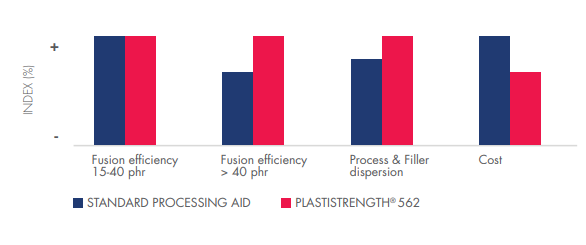

Filler dispersion Thanks to its high molecular weight and innovative composition, Plastistrength® 562 process aid delivers optimum melt strength and fusion behaviour to rigid PVC formulations. This allows for better dispersed particles within the PVC matrix, which improves mechanical properties as well as the surface finish quality

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Markets

- Applications

- Product Applications

Plastistrength® 562 process aid is particularly recommended for vinyl siding, window sills, wall panels, pipes and any other kind of rigid PVC application.

Customers should evaluate Plastistrength® 562 process aid in their own laboratories to optimum conditions for use in their processes and applications. Arkema’s Technical Service Team is available to discuss your application requirements, provide formulation guidance and laboratory testing as needed.

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Appearance

- White powder

- Color (SDS)

- White

- Item Number

- Odor (SDS)

- very faint ester like

- Other Hazards

- Mechanical irritation effects from dust exposure are possible at ambient temperature. This product may release fume and/or vapor of variable composition depending on processing time and temperature.

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Volatile Content 1.0 %(W/W) %(W/W) - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.5 g/cm³ g/cm³ Sieve Fractionation (Retained) 2.0 % % 40 Mesh Specific Gravity 1.11 - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) 824.0-878.0 °F °F - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 730.0 d d