Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Fluids & Lubricants Functions

- Product Code

- MITM15287

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Applicable Processes

- Compatible Polymers & Resins

- Fluids & Lubricants End Use

- Fluids & Lubricants Type

- Markets

- Applications

- Product Applications

Fields of industrial application:

- Low viscous base oil component for high performance lubricants with low friction coefficients, excellent wear properties and good thermal stability.

- Base oil for manufacturing greases with good low temperature behavior.

- Lubricity improver for fully synthetic metal working fluids.

Properties

- Physical Form

- Soluble In

- Note

- Typical Properties are for guidance only and not to be taken as product specifications. The tolerances are given in the product specification sheet.

- * Contact angle of water on V2A steel: 64°.

- ** Surface tension of water: 71.6 mN/m.

- Product Properties

- POLYGLYKOL BM 11/580 is a clear, neutral viscous liquid at room temperature. It displays an extremely low solidification point of lower than -62°C and no evaporation loss even at temperatures as high as 100°C.

- POLYGLYKOL BM 11/580 has a very high viscosity index of around 210 despite its low molecular weight. It is soluble in both water and low viscous naphthenic oil.

Technical Details & Test Data

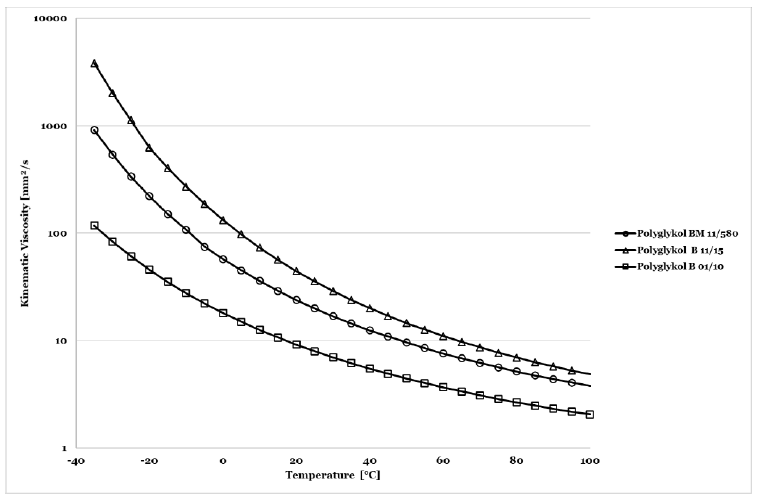

- Viscosity/Temperature Behaviour of Polyglykol BM 11/580

Polyglykol BM 11/580 is the ideal component for low temperature applications. As shown in Figure 1, the viscosity of Polyglykol BM11/580 is relatively low even at -40°C.

Figure 1: Temperature – Kinematic viscosity scan:

- Thermo-Oxidative Degradation

To increase the thermo-oxidative stability, Lubricant Additive 1655 (LA 1655) can be used:

Addition of

LA 1655Temperature

5% mass lossTemperature

10% mass lossCenter

point TInflection

point TResidue °C °C °C °C °C 175.8 187.9 222.3 234.5 0 + 3% LA

1655216 236 261.6 268.3 1.3 + 8% LA

1655222 245 278.8 289.2 3.8 - Elastomer Compatibility - EPDM

Compared to mineral oils and esters, such as TMP trioleate esters, Polyglykol BM 11/580 has a very good compatibility with EPDM sealings:

Base oil Mineral oil HLP 46 Polyglykol BM 11/580 +4% Lubricant Additive 1655 Nᵃ⁾ Ester TMP Trioleate based Hydraulic Fluid ISO 4925 Requirements

Relative Change in Volume 1.17 0.06 0.49 Min. 0%,

Max. 10%

Change in Hardness IRHD 33 -3 -24 Min. 0%,

Max. -15

- Conditions: EPDM RM 69, 100°C, 7d, Average of two measurements.

- ᵃ⁾ Lubricant Additive 1655 N - additive package designed for polyglycols to improve oxidation stability, corrosion, and EP/AW properties. Replaced with Lubricant Additve 1655.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000004

- Principal

Storage & Handling

- Storage Conditions

When stored in a cold, dry place in a closed container POLYGLYKOL BM 11/580 can be kept for at least two years.

Other

- Appearance

- Clear viscous liquid

- Appearance (SDS)

- Liquid

- Color (SDS)

- Light yellow

- Item Number

- Odor (SDS)

- Characteristic

- Other Hazards

- None known

- Protect from Freezing

- Yes

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 5.0-7.0 - DIN EN 1262 10% w/w solution in water - Material Composition

Value Units Test Method / Conditions Potassium Content max. 10.0 ppm ppm Sodium Content max. 10.0 ppm ppm - Mechanical Properties

Value Units Test Method / Conditions Contact Angle 33.9 - 5% in aqueous solution*, V2A Steel Scar Diameter 0.55 - DIN 51350-3B 300N, 1 hr Weld Load 1200.0 N N - Optical Properties

Value Units Test Method / Conditions Color Scale max. 100.0 APHA APHA Refractive Index 1.4464 - DIN 51432 at 20°C - Physical Properties

Value Units Test Method / Conditions Cloud Point 62.5 °C °C 1% aqueous solution Cloud Point 50.0 °C °C 5g in 25g 25% BDG Density 1.0 g/cm³ g/cm³ DIN 51757 at 20°C Flash Point 199.0 °C °C DIN 51376 Molecular Weight 1400.0 g/mol g/mol Pour Point max. -72.0 °C °C ASTM D7346 Pour Point max. -62.0 °C °C ISO 3016 Viscosity 23.0 mm²/s mm²/s DIN 51562 at 20°C Viscosity 12.7 mm²/s mm²/s DIN 51562 at 40°C Viscosity Index 210.0 - ASTM D2270 - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) 644.0 °F °F DIN EN 14522 Boiling Point (SDS) min. 572.0 °F °F Decomposition Energy (SDS) 353.0 kJ/kg kJ/kg mass Decomposition Temperature (SDS) approx. 657.0 °F °F Density (SDS) approx. 1.005 g/cm³ g/cm³ DIN 51757 at 50°C Flash Point (SDS) approx. 322.0 °F °F ASTM D92 Flash Point (SDS) approx. 322.0 °F °F Closed Cup Kinematic Viscosity (SDS) approx. 12.7 - DIN 51562 at 40°C Log Partition Coefficient (Log Pow) (SDS) 0.88 - Log Pow, n-Octanol/Water Solidification Point (SDS) approx. -58.0 °C °C ASTM D1177 Vapor Pressure (SDS) max. 0.001 - At 68°F Viscosity (SDS) 12.7 mm²/s mm²/s DIN 51562 at 38°C pH (SDS) 5.0-7.0 - at 20°C, 10% Concentration - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 2.0 - - Thermal Properties

Value Units Test Method / Conditions Ignition Temperature 340.0 °C °C DIN EN 14522