Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Chemical Name

- Country of Origin

- Product Code

- MITM13862

- Single Ingredient

- Yes

- Synonyms

- (±)-1,2-Propanediol, (±)-Propylene glycol, (RS)-1,2-Propanediol, 1,2-(RS)-Propanediol, 1,2-Dihydroxypropane, 1,2-Propanediol, 1,2-Propylene glycol, 2-Hydroxypropanol, 2,3-Propanediol, DL-1,2-Propanediol, dl-Propylene glycol, Isopropylene glycol, Methylethyl glycol, Methylethylene glycol, Monopropylene glycol, NSC 69860, α-Propylene glycol

- Technologies

- Product Families

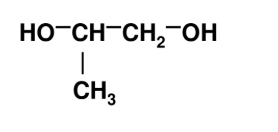

- Chemical Structure

Features & Benefits

- Labeling Claims

- Product Benefits

- Matting performance: achieve generally a minimum gloss of about 3GU at 60° and also depending on the coating resin sensitivity;

- Powdering process: pre-mix, extrude and ground with other raw materials; no dry blending requirement;

- Appearance: fine surface, good flowing, and smooth;

- Weather resistance: The matting agent itself has good UV resistance and weather resistance;

- Mechanical properties: Impact strength can pass +50KG*cm, -40KG*cm

- In order to obtain good mechanical properties and matting properties, it is necessary to ensure the curing temperature;

Applications & Uses

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S002321

- Principal

Storage & Handling

- Storage Conditions

- We define Shelf Life in terms of a product's conformance to sales specifications, after a specified period of time. Using this as a guide, the product should retain its conformance to sales specifications for a period of at least two years after shipment, if the product is stored at less than 100° Fahrenheit in its undamaged, unopened, factory packaged container.

- In general, the user should determine the suitability of any chemical compound, no matter what the shelf life or length of time of storage. Each user should conduct a sufficient investigation to establish the suitability of any product for his intended use.

- Storage and Handling Condition

- Propylene Glycol is a high-purity material, which must be handled with special precautions to avoid contamination.

- Under ordinary conditions, mild steel is a satisfactory material of construction; however, for long-term storage and where iron contamination and color are objectionable, stainless steel or aluminum vessels are recommended.

- For additional information on handling and storage of Propylene Glycol, please contact the Huntsman Technical Service Section. Product is available in barges, lined tank cars and dedicated tank trucks. Certain government regulations may apply at the time of shipment.

Other

- Appearance

- Substantially free of suspended matter

- Appearance (SDS)

- Liquid

- Color (SDS)

- Colorless, clear

- Item Number

- Odor (SDS)

- Odorless

- Other Hazards

- THIS PRODUCT IS NOT TO BE USED TO PRODUCE FOGS OR MISTS IN THEATRICAL, MUSICAL, OR OTHER ENTERTAINMENT PERFORMANCES. THIS PRODUCT IS NOT TO BE USED AS A COMPONENT OF THE LIQUID USED IN ELECTRONIC CIGARETTE (ECIGARETTE) PRODUCTS.

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions Acid Value max. 0.005 %(W/W) %(W/W) Internal Method Acetic Acid Ash Content max. 0.005 %(W/W) %(W/W) Internal Method Assay min. 99.0 %(W/W) %(W/W) Internal Method Propylene Glycol - Material Composition

Value Units Test Method / Conditions Chloride Content max. 1.0 ppm ppm Internal Method Iron Content max. 1.0 % % Internal Method - Optical Properties

Value Units Test Method / Conditions Color Scale max. 10.0 Pt-Co Pt-Co Refractive Index min. 1.431 - at 20°C - Physical Properties

Value Units Test Method / Conditions Boiling Point max. 189.0 °C °C Density 8.64 lb/gal lb/gal at 20°C Flash Point 212.0 °F °F Pensky-Martens Closed Cup (PMCC) Freeze Point max. -76.0 °C °C Initial Boiling Point min. 185.0 °C °C Molecular Weight 76.0 g/mol g/mol neutralizing potential acid Solubility in Water min. 10.0 % % Specific Gravity min. 1.035 - at 25/25°C Vapor Pressure max. 1.0 mm Hg mm Hg at 20°C Viscosity 60.0 cPs cPs - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) approx. 700.0 °F °F Boiling Point (SDS) approx. 370.0 °F °F at approx. 1013.08 hPa Density (SDS) 1.04 g/cm³ g/cm³ at 20°C Evaporation Rate (SDS) 0.01 kg/h kg/h Flash Point (SDS) approx. 228.0 °F °F Closed Cup Freeze Point (SDS) approx. -60.0 °C °C Kinematic Viscosity (SDS) max. 20.0 mm²/s mm²/s At 104°F Kinematic Viscosity (SDS) max. 20.0 mm²/s mm²/s at 40°C Log Partition Coefficient (Log Pow) (SDS) -1.0 - Log Partition Coefficient (Log Pow) (SDS) -1.0 - Log Pow, n-Octanol/Water Lower Explosion Limit (SDS) approx. 2.6 %(V) %(V) Relative Density (SDS) 1.04 - at 25°C Relative Vapor Density (SDS) approx. 2.6 - at 15 - 32°C Upper Explosion Limit (SDS) approx. 12.5 %(V) %(V) Vapor Pressure (SDS) max. 0.1333 hPa hPa Vapor Pressure (SDS) max. 0.1333 hPa hPa at 25°C Viscosity (SDS) approx. 46.0 mPa.s mPa.s at 25°C Viscosity (SDS) 46.0 mPa.s mPa.s at 760 mmHg pH (SDS) 7.0 - pH (SDS) approx. 7.0 - neutral - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 2.0 yr yr