Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Function

- Resin

- Plastics & Elastomers Functions

- Product Code

- MITM14912

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

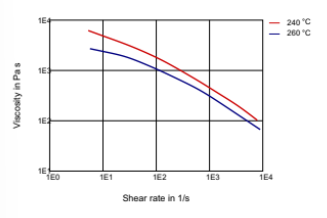

- Processing Information

- Typical melt temperature (Min / Recommended / Max) : 230℃/250℃ / 280℃.

- Drying time and temperature (only necessary for bags opened for more than two hours) : 4-8 hours at 80-90℃.

Properties

- Physical Form

Technical Details & Test Data

- Technical Data

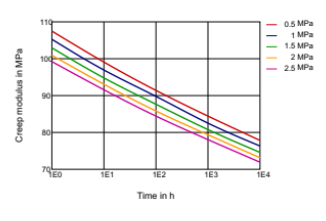

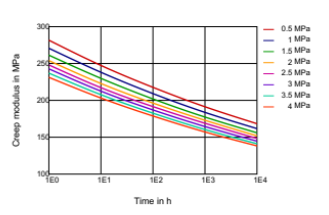

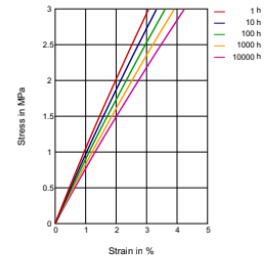

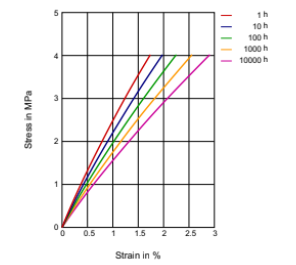

- Modulus Data

- Modulus Data

- Modulus Data

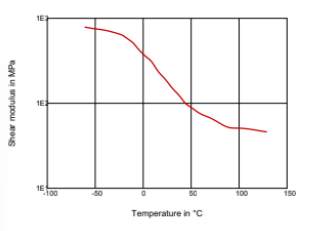

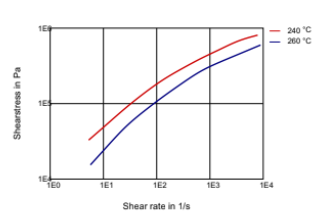

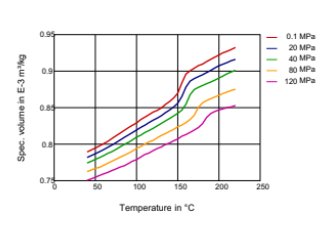

- Technical Data

- Technical Data

- Technical Data

- Technical Data

- Technical Data

- Technical Data

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Color (SDS)

- Black

- Item Number

- Odor (SDS)

- Odorless

- Other Hazards

- Processing may release vapors and/or fumes which cause eye, skin and respiratory tract irritation, Prolonged or repeated exposure may cause: headache, drowsiness, nausea, weakness, (severity of effects depends on extent of exposure).

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Electrical Properties

Value Units Test Method / Conditions Dielectric Constant 9.0 - IEC 60250 at 100 Hz, dry Dielectric Constant 4.0 - IEC 60250 at 1MHz, dry Dielectric Strength 23.0 kV/mm kV/mm IEC 60243-1 condensed Dissipation Factor 0.244 tan δ tan δ IEC 60250 at 100 Hz, dry Dissipation Factor 0.104 tan δ tan δ IEC 60250 at 1MHz, dry Surface Resistance 500000000000.0 Ω Ω IEC 60093 condensed Volume Resistivity 1000000000.0 Ω-cm Ω-cm IEC 60093 condensed - Material Composition

Value Units Test Method / Conditions Carbon Content min. 89.0 % % ASTM D6866 - Mechanical Properties

Value Units Test Method / Conditions Charpy Impact Strength 7.0 kJ/m² kJ/m² ISO 179-1EA at -30°C, condensed, notched Hardness 60.0 Shore D Shore D Nominal Strain at Break min. 50.0 % % ISO 527-1 condensed, at break, nominal Nominal Strain at Break min. 50.0 % % ISO 527-2 condensed, at break, nominal Puncture Energy 70.0 J J ISO 6603 at -30°C, condensed Puncture Force 6000.0 N N ISO 6603 at -30°C Strain at Yield 50.0 % % ISO 527-1 condensed Strain at Yield 50.0 % % ISO 527-2 condensed Tensile Modulus 345.0 MPa MPa ISO 527-1 condensed Tensile Modulus 345.0 MPa MPa ISO 527-2 condensed - Physical Properties

Value Units Test Method / Conditions Density 1040.0 kg/m³ kg/m³ ISO 1183 condensed Density 1040.0 kg/m³ kg/m³ ISO 1183 dry basis Load/Unload Temperature 130.0 °C °C ISO 75-1 at 0.45 MPa, dry, deflection under load Load/Unload Temperature 45.0 °C °C ISO 75-1 at 1.80 MPa, dry, deflection under load Load/Unload Temperature 130.0 °C °C ISO 75-2 at 0.45 MPa, dry, deflection under load Load/Unload Temperature 45.0 °C °C ISO 75-2 at 1.80 MPa, dry, deflection under load Melting Point 181.0 °C °C ISO 11357-3 at 10°C/min Melting Point 181.0 °C °C ISO 11357-1 at 10°C/min Softening Point 140.0 °C °C ISO 306 at 50°C/h, 50N, dry Water Absorption 1.6 % % ISO 62 dry basis - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Decomposition Temperature (SDS) 350.0 °C °C Lower Explosion Limit (SDS) 89.0 % % at 85⁰C Melting Point (SDS) 175.0-190.0 °C °C - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 24.0 mo mo - Thermal Properties

Value Units Test Method / Conditions Coefficient of Thermal Expansion 0.00011 /K /K ISO 11359-1 dry, parallel Coefficient of Thermal Expansion 0.00011 /K /K ISO 11359-2 parallel, dry