Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Product Code

- MITM09357

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

Properties

- Physical Form

- Soluble In

Technical Details & Test Data

- Technical Data

Stabaxol® I Powder is normally dissolved in the polyester polyol; alternatively, it may be added to the pre-polymer (only with terminal OH groups). An addition of 2.5 part by weight Stabaxol® I Powder to 100 parts by weight polyester polyol will increase the resistance to hydrolysis approximately four times. As Stabaxol® I Powder tends to bloom in certain goods, the addition should not exceed 2 parts by weight (on 100 parts polyester polyol).

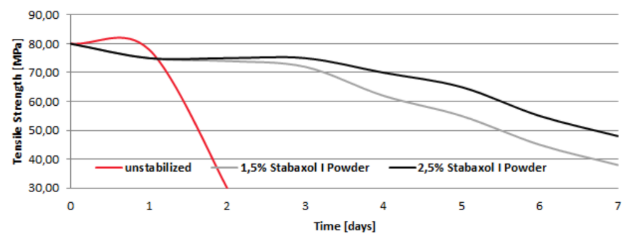

Tensile Strength after Hydrolysis

PET monofilaments in saturated vapor at 120°C

Prior tests should always be carried out to determine the most suitable dosage, however. To be most effective, Stabaxol® I Powder should be added to the polyester polyol during the warming-up period, starting at a minimum temperature of 50 °C (122 °F), to a maximum temperature of 120 °C (248 °F). As Stabaxol® I Powder does not disperse readily (it may float undissolved on the surface), it should be stirred intensively. Stabaxol® I Powder may slightly accelerate the crosslinking reaction (polyester polyol/iscoyanate). This can be counteracted by adding a very small amount of an organic acid (e.g. citric acid). For adhesives we recommend to add 1-2 parts by weight Stabaxol® I Powder to 100 parts by weight adhesive.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000008

- Principal

Storage & Handling

- Storage Conditions

Stabaxol® I Powder can be stored for at least 24 month under cool, dry conditions. The powder tends to form lumps, especially towards the end of the storage period.

Other

- Appearance

- White to slightly yellowish powder tends to form lumps

- Appearance (SDS)

- Solid crystalline

- Color (SDS)

- Light yellow

- Flammable Nature (SDS)

- Sustains combustion

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Slight

- Other Hazards

- None known

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Carbodiimide Content min. 10.5 % % - Physical Properties

Value Units Test Method / Conditions Density 0.95 g/cm³ g/cm³ At 50°C Melting Point 50.0 °C °C Viscosity 16.0-24.0 mPa.s mPa.s At 50°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) min. 430.0 °C °C Bulk Density (SDS) 600.0-700.0 kg/m³ kg/m³ at 20°C Decomposition Temperature (SDS) min. 240.0 °C °C Density (SDS) 0.95 g/cm³ g/cm³ At 50°C Flash Point (SDS) 194.0 °C °C Open Cup Melting Point (SDS) 40.0-45.0 °C °C Self Ignition Temperature (SDS) min. 430.0 °C °C - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 24.0 mo mo