Enhanced TDS

Identification & Functionality

- Function

- Activator

- Plastics & Elastomers Functions

- Product Code

- MITM09324

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Compatible Polymers & Resins

- Markets

- Applications

- Processing Information

- Processing temperatures:

- Melt: 110-130 °C

- Mold: 130-160 °C

- Recommended Dosage: 0.5-0.7 % by weight

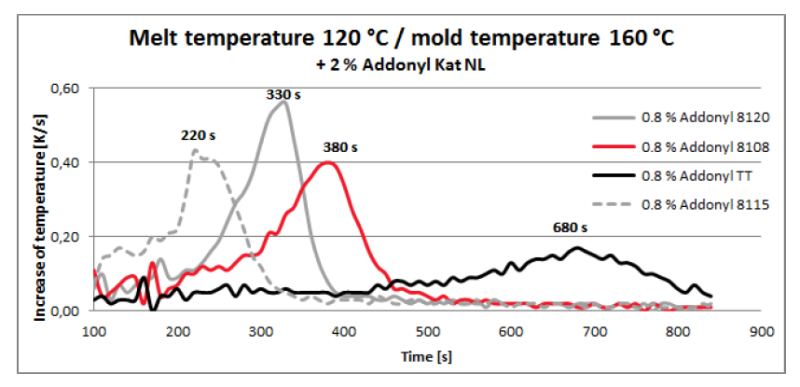

- The following diagram shows the reactivity of various Addonyl activators, with the same weight dosing, subject to time:

-

- Processing temperatures:

- Application Information

- Addonyl® 8108 is used as an activator during the production of Cast Nylon (PA-6 G). In combination with the catalyst Addonyl® Kat NL

- Use

- The reactivity of the polymerizing melt is influenced by various factors. Recommended an activator concentration of at least 0.5 % by weight. The quantity of the activator to be used, however, decisively depends on the size and form of the casting mold. Addonyl® 8108 is easily soluble in molten caprolactam. The caprolactam melt containing the activator is susceptible to oxidation. Thus, we recommend working under inert gas.

Properties

- Physical Form

- Soluble In

Safety & Health

- Safety Precautions

A receiving inspection is recommended. In moist conditions, with the formation of carbondioxide, Addonyl® 8108 converts to a solid, high-melting and insoluble polyurea.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000008

- Principal

Storage & Handling

- Storage and Handling Conditions

- Addonyl® 8108 has a shelf life of at least 24 months if handled correctly. The product may occasionally turn reddish during storage.

- Heat sensitivity: starting from + 50°C

- Frost sensitivity: starting from - 10°C

- Keep containers dry and tightly sealed.

- Addonyl® 8108 has a shelf life of at least 24 months if handled correctly. The product may occasionally turn reddish during storage.

Other

- Appearance

- Yellowish liquid which may occassionally tend to a redish color during storage with a weak solvent - type odor

- Color (SDS)

- Yellow

- Item Number

- Odor (SDS)

- Solvent like

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) 0.5-0.7 %(W/W) %(W/W) - Material Composition

Value Units Test Method / Conditions Isocyanate Group Content 15.0-17.0 % % - Physical Properties

Value Units Test Method / Conditions Density 1.082 g/cm³ g/cm³ at 20°C Storage Temperature max. 122.0 °F °F Viscosity 100.0 mPa.s mPa.s at 23°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 210.0 °C °C At 1013 Hpa Decomposition Temperature (SDS) min. 300.0 °C °C Density (SDS) 1.082 g/cm³ g/cm³ Explosion Limit (SDS) 1.3-7.7 % % Flash Point (SDS) 136.0 °C °C Closed Cup Flash Point (SDS) 136.0 °C °C DIN ISO 2592 Ignition Temperature (SDS) 245.0 °C °C Kinematic Viscosity (SDS) 0.021 cm²/s cm²/s Vapor Pressure (SDS) 0.18 hPa hPa at 20°C Viscosity (SDS) 100.0 mPa.s mPa.s - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 24.0 mo mo