Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Country of Origin

- Function

- Pigment

- Pigment Type

- Plastics & Elastomers Functions

- Product Code

- MITM14400

- Single Ingredient

- Yes

- Synonyms

- 5,5'-Azobis-2,4,6(1H,3H,5H)-pyrimidinetrione

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Compatible Polymers & Resins

- Product Applications

Coloring of PP fibres, polyamide fibres, polyolefine and polyamide

Properties

Technical Details & Test Data

- Test Data

Materials used for testing of Heat stability and Lightfastness

- HD-PE: Sabic M80063

- PP: Stamylan P

- PS: BASF Polystyrene 143E

- PA 6: LANXESS Durethan B30S

- PA 6.6: LANXESS Durethan A30H 1.0

- ABS: LANXESS Novodur P2X

- PET: Voridian 9921 W

- PBT: LANXESS Pocan B1505

- PC: Bayer MaterialScience Makrolon 2800

- TiO₂: Kerr McGee Tronox R-FK-3

- Tehnical Data

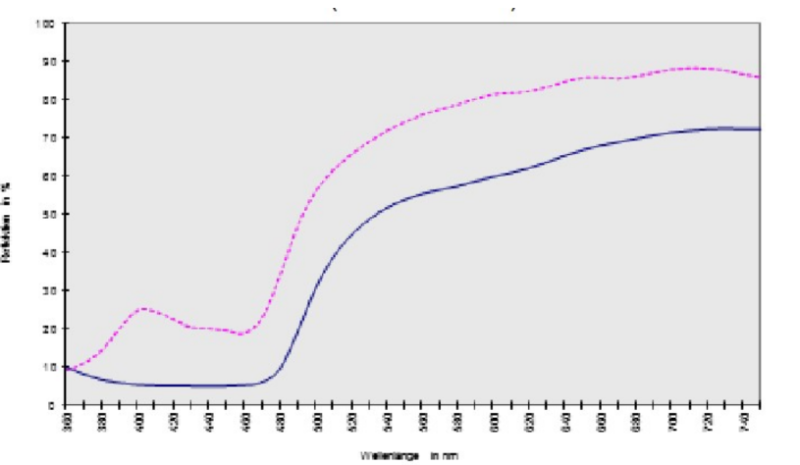

Reflection curve BAYPLAST® Yellow 5GN 01/P in PP

(2mm thickness)

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000008

- Principal

Other

- Appearance

- Yellow powder

- Appearance (SDS)

- Powder

- Color (SDS)

- Yellow

- Dust Explosion Class (SDS)

- Capable of Causing a Dust Explosion

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Odorless

- Other Hazards

- None known

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Physical Properties

Value Units Test Method / Conditions Bulk Density 0.3 g/cm³ g/cm³ DIN ISO 787-11 Density 1.6 g/cm³ g/cm³ at 23°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) min. 572.0 °F °F At 1013 Hpa Bulk Density (SDS) 300.0 kg/m³ kg/m³ Burning Number (SDS) 3.0 - VDI 2263-1 at 20°C Burning Number (SDS) 3.0 - VDI 2263 at 100°C Decomposition Temperature (SDS) min. 842.0 °F °F Self Ignition Temperature (SDS) min. 410.0 °F °F Auto ignition temperature pH (SDS) 6.0 - 5% concentration - Shelf Life & Stability

Value Units Test Method / Conditions Bleed Resistance (Plasticized PVC) 5.0 - DIN 53775 Light Fastness 8.0 - DIN EN ISO 4892-2 acrylonitrile butadiene styrene, Reduction with white Light Fastness 7.0-8.0 - DIN EN ISO 4892-2 Full shade, ABS Light Fastness 8.0 - DIN EN ISO 4892-2 Full Shade, PC Light Fastness 8.0 - DIN EN ISO 4892-2 Full Shade, PET Light Fastness 8.0 - DIN EN ISO 4892-2 Full shade, PS Light Fastness 8.0 - DIN EN ISO 4892-2 HD-PE, Full Shade Light Fastness 8.0 - DIN EN ISO 4892-2 HD-PE, Reduction with white Light Fastness 8.0 - DIN EN ISO 4892-2 PA 6.6, Full Shade Light Fastness 8.0 - DIN EN ISO 4892-2 PA 6.6, Reduction with white Light Fastness 8.0 - DIN EN ISO 4892-2 PA 6, Full Shade Light Fastness 8.0 - DIN EN ISO 4892-2 PA 6, White Reduction Light Fastness 6.0-7.0 - DIN EN ISO 4892-2 PBT, Full Shade Light Fastness 8.0 - DIN EN ISO 4892-2 PBT, Reduction with white Light Fastness 8.0 - DIN EN ISO 4892-2 PC, Reduction with white Light Fastness 8.0 - DIN EN ISO 4892-2 PET, Reduction with white Light Fastness 8.0 - DIN EN ISO 4892-2 PP, Full Shade Light Fastness 8.0 - DIN EN ISO 4892-2 PP, Reduction with white Light Fastness 8.0 - DIN EN ISO 4892-2 PS, Reduction with white Shelf Life 60.0 mo mo