Enhanced TDS

Identification & Functionality

- Chemical Family

- Country of Origin

- Function

- Impact Modifier

- Plastics & Elastomers Functions

- Product Code

- MITM10315

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Benefits

- DurastrengthⓇ 480 impact modifier has a high rubber content allowing excellent impact at ambient and cold temperatures.

Property Neat High Flow PC PC + 5% D480 IM

Impact Energy*

(ft-lb/in)0°C

2

12

-10°C

2

11

-20°C

2

8.5

*ASTM D256 specifications for notched IZOD impact tests

- Durastrength 480 impact modifier provides excellent weatherability, opening the door for use in applications that demand good colorability and retention of mechanical properties upon exposure to the elements. This enabling technology is especially designed for mold-in color applications.

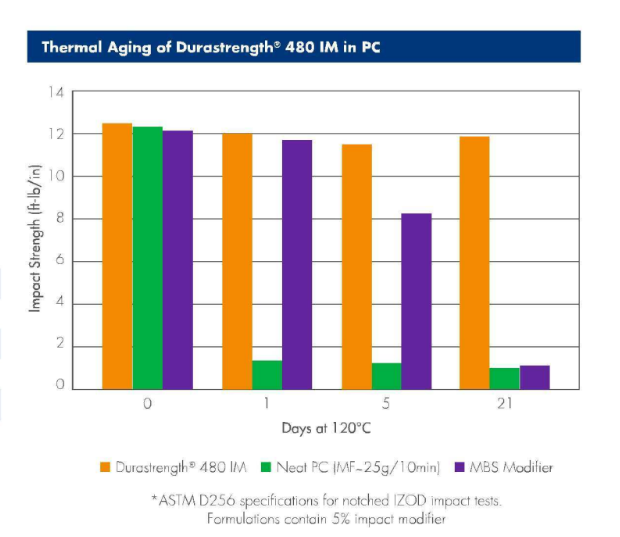

- The all-acrylic chemistry of the Durastrength 480 impact modifier provides exceptional impact retention needed for high temperature end- use applications.

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Product Uses

Durastrength® 480 impact modifier is recommended for use in PC and PC blends where superior low temperature impact and weatherability are required.

Durastrength® 480 impact modifier is recommended for use in application such as automotives, lawn and garden equipment, and recreational vehicles where weatherability and good low temperature impact are important.

Prospective clients should evaluate Durastrength 480 impact modifier in their own laboratories to establish optimum conditions for used in their process and applications. Arkema's Technical Service Team is available to diskuss your application requirements, provide formulations guidance and laboratory testing as needed.

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Appearance (SDS)

- Solid

- Color (SDS)

- White

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Monomers very faint

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Volatile Content max. 1.0 % % - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.4 g/m³ g/m³ Sieve Fractionation (Retained) max. 2.0 % % + 50 Mesh Specific Gravity 1.02 - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) 470.0 °C °C Bulk Density (SDS) 250.0-500.0 kg/m³ kg/m³ Decomposition Temperature (SDS) min. 250.0 °C °C Density (SDS) 1090.0 kg/m³ kg/m³ at 23°C Log Partition Coefficient (Log Pow) (SDS) 3.32 - Log Kow Pow, n-Octanol/Water Log Partition Coefficient (Log Pow) (SDS) 3.32 - n-Octanol/Water - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d