Enhanced TDS

Identification & Functionality

- Chemical Family

- Country of Origin

- Function

- Impact Modifier

- Plastics & Elastomers Functions

- Product Code

- MITM13331

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Benefits

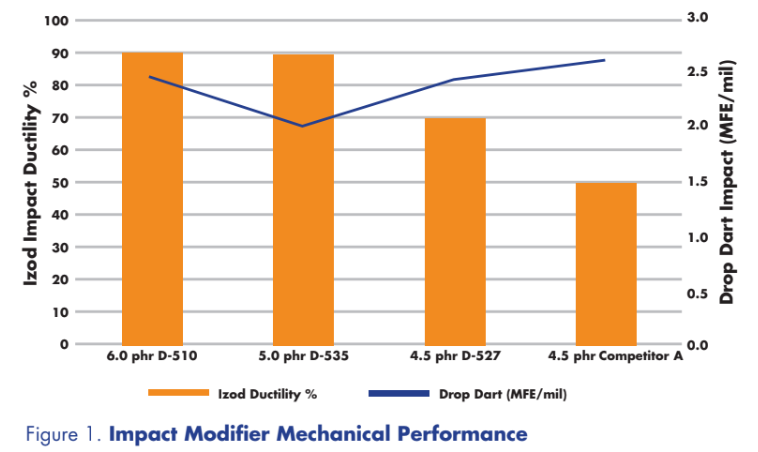

Durastrength® 527 delivers industry-standard impact/mechanical strengths at signifi cantly lower loading levels (see Figure 1) compared to other Durastrength® impact modifi ers or a typical competitive product.

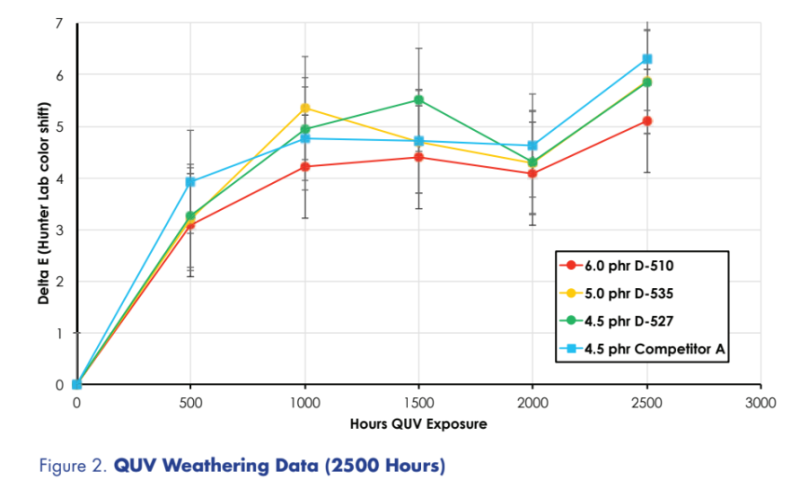

Formulations incorporating Durastrength® 527 impact modifi er meet or exceed industry standards for weathering performance. Figure 2 details QUV data comparing Durastrength® 527 to other Durastrength® impact modifi ers as well as a typical competitive product. Performance is consistent across all technologies and rubber content.

Durastrength® 527 impact modifier offers rheology behavior that meets industry standards. Figure 3 shows no significant differences in fusion time or torque for Durastrength® 527 in a weatherable profile formulation compared to other Durastrength® impact modifiers or a typical competitive product.

Figure 3. Brabender Rheology Expanded Fusion and Thermal Stability 170°C / 75 RPM / 65g 190°C / 75 RPM / 65g Additive PHR Fusion Time (sec) Fusion Torque (mg) Fusion Time

(sec)Fusion Torque

(mg)Eq. Torque

(mg)Stability Time

(min)Durastrength® 510 6 46 4364 30 3810 17823 8.4 Durastrength® 535 5 44 3997 22 3616 1757 7.6 Durastrength® 527 4.5 48 3881 30 3638 1723 8.4 Competitor A 4.5 44 3870 26 3645 1663 7.7

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Markets

- Applications

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Color (SDS)

- White

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Slightly acrylic

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Volatile Content max. 1.2 % % - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.48 g/cm³ g/cm³ Sieve Fractionation (Retained) max. 15.0 % % + 50 Mesh Specific Gravity 1.1 - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Specific Gravity (SDS) 0.95-1.1 - Water = 1, liquid - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d