Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Polymer Name

- Product Code

- MITM16749

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Processing Conditions

- Typical melt temperature (Min / Recommended / Max) – Injection Molding: 230°C / 260°C / 290°C (445°F / 500°F / 555°F).

- Typical mold temperature – Injection molding: 20–60°C (70–140°F).

- Drying time and temperature: 65–75°C (150–165°F) / 4–6 hours.

Transformation Process:

- Extrusion - General

- Film Extrusion

- Injection Molding

- Tube Extrusion

Properties

Technical Details & Test Data

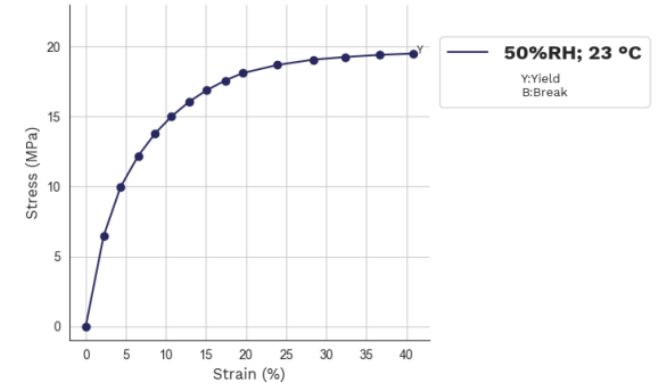

- Stress vs Strain Graph

Stress-Strain Graph:

PEBAX® RNEW® 63R53 SP 01

Principal Information

- Group Principal Number

- S000003

- Principal

Storage & Handling

- Storage Conditions

Two years from the date of delivery, when stored properly (sealed bags, appropriate moisture, UV protection and temperature).

Other

- Appearance (SDS)

- Colorless to slightly yellow

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Carbon Content 77.0 % % ASTM D6866 - Mechanical Properties

Value Units Test Method / Conditions Flexural Modulus 245.0 MPa MPa ISO 178 at 23°C, conditioned Hardness 56.0 Shore D Shore D ISO 868 at 15s, conditioned Nominal Strain at Break min. 400.0 % % ISO 527-2 at 23°C, 50 mm/min, conditioned, at break Strain at Yield 40.0 % % ISO 527-2 at 23°C, 50 mm/min, conditioned Stress 51.0 MPa MPa Stress at Yield 19.0 MPa MPa ISO 527-2 at 23°C, 50 mm/min, conditioned Tensile Modulus 245.0 MPa MPa ISO 527-2 at 23°C, 1 mm/min - Physical Properties

Value Units Test Method / Conditions Humidity Absorption 0.8 % % ISO 62 at 23°C / 50%HR, equilibrium Melting Point 180.0 °C °C ISO 11357-3 at 10°C/min Melting Point 180.0 °C °C ISO 11357-1 at 10°C/min Shrinkage 1.5 % % ISO 294-4 Normal (t+24h) Shrinkage 1.4 % % ISO 294-4 parallel, t+24h Specific Gravity 1.03 - ISO 1183-1 at 23°C Storage Temperature 140.0 °F °F Water Absorption 1.5 % % ISO 62 at 23°C, immersion, equilibrium - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) 370.0-450.0 °C °C Bulk Density (SDS) 550.0-650.0 kg/m³ kg/m³ Density (SDS) 1.03 g/cm³ g/cm³ Melting Point (SDS) 180.0 °C °C Solubility In Water (SDS) max. 1.0 mg/L mg/L At 20°C - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 2.0 yr yr