Enhanced TDS

Identification & Functionality

- Chemical Family

- Country of Origin

- Plastics & Elastomers Functions

- Product Code

- MITM10321

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Benefits

Lubricity

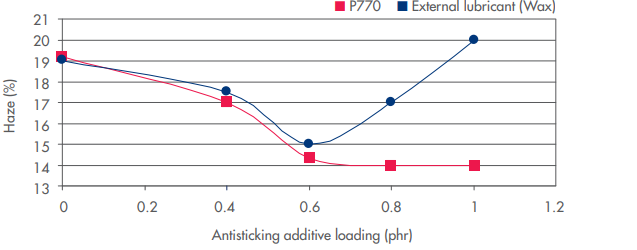

Plastistrength® 770 process aid provides excellent lubricity to vinyl formulations, while imparting high optical properties and surface quality to the end products, and retaining printability. Plastistrength® 770 process aid can replace external lubricants by providing efficient antisticking effect without any plate-out issue.

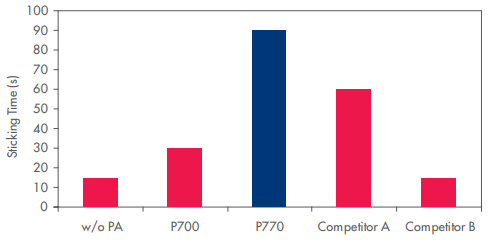

Superior efficiency of P770 PA (Processing temperature = 205°C)

Transparent formulation, organotin stabilized, processed on a two-roll mill equipment (diam 150), with 1.2phr of process aid

Optimized

Optimizedoutput The use of Plastistrength® 770 process aid enables manufacturers of rigid vinyl products to eliminate excessive downtime due to sticking and burning of processed compounds, with limited effect on PVC fusion and rheology.

Property Neat PVC compounds + 1.2 phr P770 PA Melt viscosity (x1000 Pa.s) 3.6 3.7 Fusion time at 170°C (s) 225 210 Better value in use

The unique design and chemical composition of Plastistrength® 770 process aid makes it more efficient than any other type of anti-sticking process aid. This higher efficiency can be used to either imporve quality or to generate cost savings by doseage reduction.

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Product Applications

- Plastistrength® 770 process aid is recommended for PVC and CPVC applications where good metal release from process equipment is required such as high-speed extrusion, calendering, injection molding and blow molding.

- Plastistrength® 770 is commonly used in PVC formulations for food or pharmaceutical packaging.

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Appearance

- White powder

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Odorless

- Other Hazards

- Processing may release vapors and/or fumes which cause eye, skin and respiratory tract irritation, The product, in the form supplied, is not anticipated to produce significant adverse human health effects. Contains high molecular weight polymer(s). Effects due to processing releases: Irritating to eyes, respiratory system and skin, Prolonged or repeated exposure may cause: headache, drowsiness, nausea, weakness, (severity of effects depends on extent of exposure) , Handle in accordance with good industrial hygiene and safety practice. (powder) Mechanical irritation effects from dust exposure are possible at ambient temperature. This product may release fume and/or vapor of variable composition depending on processing time and temperature.

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Volatile Content 1.0 %(W/W) %(W/W) - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.5 g/cm³ g/cm³ Specific Gravity 1.11 - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Bulk Density (SDS) 1.11 kg/m³ kg/m³ Decomposition Temperature (SDS) 572.0 °F °F - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 730.0 d d