Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Binder

- Industrial Additives Functions

- Product Code

- MITM15372

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Industrial Additives Features

- Labeling Claims

- Product Benefits

- APE-free

- Ultra low formaldehyde*

- High tensile strength

- Stiff hand

- Excellent wash durability

- Self-crosslinking

- Good color and formulation stability

- Excellent runnability

*Ultra low formaldehyde: no formaldehyde or formaldehyde generators intentionally added.

Applications & Uses

- Coating End Applications

- Compatible Substrates & Surfaces

- Industrial Additives End Use

- Markets

- Applications

- Product Applications

- RHOPLEX® ECO-3482 combines a very soft hand with tensile strength and durability.

- The following are typical laboratory test results comparing RHOPLEX® ECO-3482 to RHOPLEX TM ST-954, a conventional self-crosslinking acrylic binder with a Tg of -23°C.

- This application was performed on wood pulp (Whatman #4 filter paper) with about 25% solids add-on.

- The samples were dried/cured at 150°C for 3 minutes in a laboratory Mathis oven.

Properties

- Physical Form

Technical Details & Test Data

- Technical Data

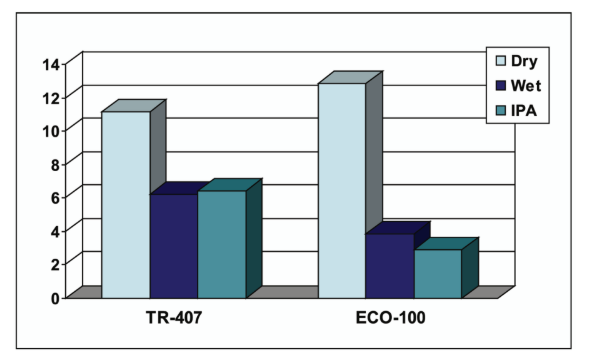

The tensile strengths were tested in the cross-machine direction and are reported in kg/inch.

For the wet and IPA strengths, the samples were soaked in water or IPA for 30 minutes before testing.

RHOPLEX® ECO-3482 has performances close to a conventional self-crosslinking binder without the associated formaldehyde emissions or residual formaldehyde in the final nonwoven.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000005

- Principal

Storage & Handling

- Handling Information

- Keep combustible and/or flammable products and their vapors away from heat, sparks, flames and other sources of ignition including static discharge.

- Processing or operating at temperatures near or above product flashpoint may pose a fire hazard.

- Use appropriate grounding and bonding techniques to manage static discharge hazards.

- Failure to maintain proper volume level when using immersion heaters can expose tank and solution to excessive heat resulting in a possible combustion hazard, particularly when plastic tanks are used.

- Storage Conditions

Store products in tightly closed original containers at temperatures recommended on the product label.

Other

- Color (SDS)

- White milky

- Item Number

- Odor (SDS)

- Acrylic like

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 5.5 - - Material Composition

Value Units Test Method / Conditions Solid Content 43.0 % % - Physical Properties

Value Units Test Method / Conditions Density 8.7 lb/gal lb/gal at 25°C Glass Transition Temperature (Tg) -27.0 °C °C Specific Gravity 1.04 - Storage Temperature 34.0-120.0 °F °F Viscosity 250.0 cPs cPs Brookfield Viscometer - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C Evaporation Rate (SDS) max. 1.0 % % Butyl Acetate=1 Melting Point (SDS) 0.0 °C °C Relative Vapor Density (SDS) max. 1.0 - Air=1 Specific Gravity (SDS) 1.0-1.2 - Water = 1 Vapor Pressure (SDS) 17.0 mm Hg mm Hg at 20°C Viscosity (SDS) max. 500.0 mPa.s mPa.s Volatile Content (SDS) 56.0-57.0 % % Water pH (SDS) 4.5-6.5 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d