Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Product Code

- MITM15135

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Advantages

Stabaxol® L is liquid at room temperature and therefore it needs no heated liquid dosing system. It has a distinctly reduced amount of volatile substances compared to Stabaxol® I and it has no labeling as hazardous good.

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Product Uses

The recommendable amount of additive depends upon the acid number, the humidity and the desired hydrolysis protection effect. Rollable PUR-rubbers should be stabilized with 0.5-5 ppw of the final product, polyester polymers and thermoplastic polyurethanes with 1.5-2.5 ppw.

Properties

- Physical Form

- Soluble In

Technical Details & Test Data

- Technical Data

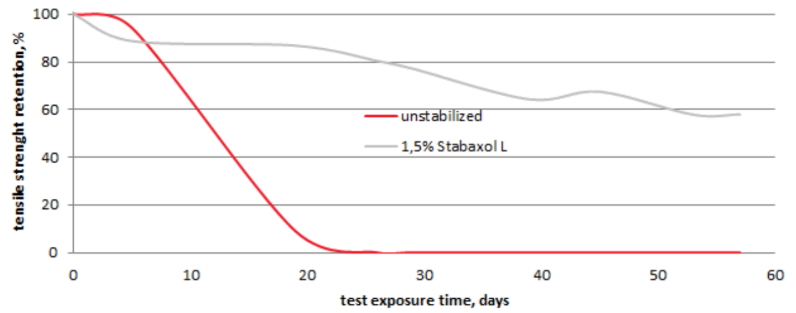

Hydrolytic Stability of polyester based TPU-Elastomers

The optimum input should always be determined by preliminary tests. Stabaxol® L can be dosed as a liquid on the respective processing unit, preferably separate. Our employees in the Technical Applications Department will gladly assist you in determining the optimal concentration. Stabaxol® L can be processed at all appropriate polymer processing units that ensure adequate dispersion of the substance in the polymer. According to our experience a twin-screw extruder with an L / D ratio > 38 is necessary. Stabaxol® L is added as a liquid in a pressure-free zone.

Principal Information

- Group Principal Number

- S000008

- Principal

Storage & Handling

- Storage Conditions

Stabaxol® L can be kept for at least 2 years under cool, dry conditions.

Other

- Appearance

- Yellowish liquid

- Appearance (SDS)

- Solid

- Color (SDS)

- Yellow

- Odor (SDS)

- Slight

- Other Hazards

- None known

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) 0.5-5.0 pbw pbw Rollable PUR-rubbers Dosage (Use Level) 1.5-2.5 pbw pbw Thermoplastic polyurethanes - Material Composition

Value Units Test Method / Conditions Carbodiimide Content max. 9.0 % % - Physical Properties

Value Units Test Method / Conditions Density 0.93 g/cm³ g/cm³ At 20°C Viscosity 870.0 - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) min. 572.0 °F °F At 1013 Hpa Density (SDS) 0.93 g/cm³ g/cm³ OECD 109 at 25°C Flash Point (SDS) 394.7 °F °F Regulation (EC) No. 440/2008, Annex, A.9 at 101.3kPa Kinematic Viscosity (SDS) 935.0 - At 20°C Log Partition Coefficient (Log Pow) (SDS) min. 8.3 - OECD 117 at 25°C, pH 7, log Pow, n-Octanol/water Melting Point (SDS) 117.0 °F °F Solubility In Water (SDS) 2.3 - OECD 105 at 20°C, pH 5 Vapor Pressure (SDS) min. 3.0 - At 25°C Viscosity (SDS) 870.0 - pH (SDS) 5.5 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 24.0 -