Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Product Code

- MITM10995

- Technologies

- Product Families

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Physical Form

- Soluble In

Technical Details & Test Data

- Technical Data

Depending on the number of acid end groups and the humidity content of the polymer to be stabilized, as well as the stabilizing effect to be obtained, it is recommended to use 0.5 - 2.5 weight-% of Stabaxol® P 110 for polyesters, polyamides and polylactides.

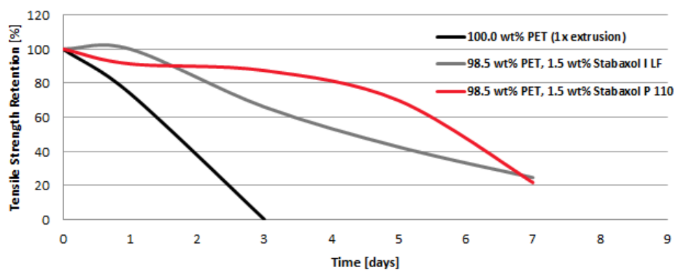

Hydrolysis of PET at 110 °C in saturated steam

The most suitable dosage depends on the requirements to be met and should always be ascertained in preliminary trials. Stabaxol® P 110 may be processed preferably by way of separate feeding or alternatively by direct incorporation as a dry blend. Stabaxol® P 110 is available in Masterbatch form too, various types based upon the corresponding polymers, and thus offering the advantage of much more easier handling in respect of dosage and homogenizing.

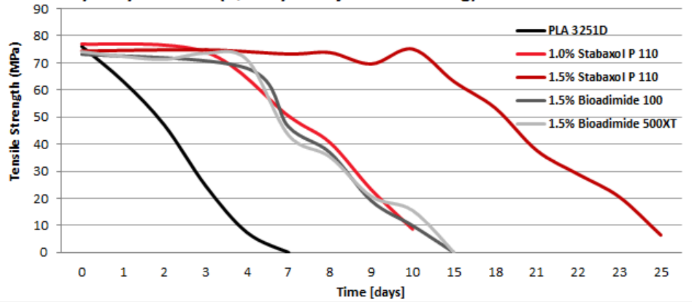

Hydrolysis of PLA (Quality for injection molding) at 65 °C in water

Stabaxol® P 110 may be processed on any unit suitable for polyester and polyamide processing which provides sufficient dispersion of the material in the polymer. In respect of the extruder equipment, experience showed that it is advisable to use a twin-screw extruder equipped with a L/D ratio > 38. Appropriate cooling of the feeding zone is recommended to avoid particle accumulation in the feeding area. At processing temperature, traces of volatile matters can escape, which may temporarily cause irritation of skin, eyes and respiratory passages. It is highly recommended to provide adequate local ventilation at all places where Stabaxol® P 110 stabilized products are exposed to temperatures exceeding 200 °C (392 °F). In particular, it is necessary to avoid direct contact with liberated vapors.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000008

- Principal

Storage & Handling

- Storage Conditions

According to experience available, if stored at about 20 °C (68 °F) in originally closed containers, Stabaxol® P 110 can be kept for at least 24 months without becoming less effective. Store in cool and dry place. During transportation or in case of prolonged storage at slightly elevated temperatures, one might observe agglomeration of the particles. Please make sure that such agglomerations are being broken prior to use.

Other

- Appearance

- Amber colored pastilles

- Appearance (SDS)

- Pastilles

- Color (SDS)

- Light, yellow

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Slight

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) 0.5-2.5 - - Material Composition

Value Units Test Method / Conditions Carbodiimide Content min. 11.5 - - Physical Properties

Value Units Test Method / Conditions Density 1.05 g/cm³ g/cm³ At 20°C Melting Point 60.0 °C °C Melting Point min. 70.0 °C °C resinous and tough Melting Point min. 90.0 °C °C viscous fluid - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (SDS) 1.05 g/cm³ g/cm³ at 20°C Melting Point (SDS) 60.0-90.0 °C °C - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 24.0 -