Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- Product Code

- MITM12807

- Single Ingredient

- Yes

- Synonyms

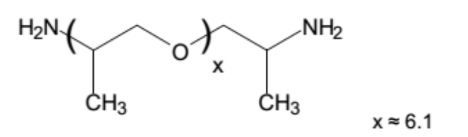

- 2-Aminopropyl-terminated polypropylene glycol, Diamino-terminated polypropylene glycol, Diaminopolypropylene glycol, Diaminopropylene glycol homopolymer, Dipropylamine poly(propylene glycol), Poly(oxypropylene)diamine, Poly(propylene oxide) bis(2-aminopropyl ether), Polypropylene glycol bis(aminopropyl) ether, Polypropylene glycol diamine, α-(2-Aminomethylethyl)-ω-(2-aminomethylethoxy) polypropylene oxide, α,ω-Diaminopolypropylene glycol

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

- Materials Features

- Product Benefits

- Low viscosity, color and vapor pressure

- Completely miscible with a variety of solvents

Applications & Uses

- Adhesive & Sealant End Applications

- Compatible Polymers & Resins

- Product Applications

- Epoxy curing agent that provides increased flexibility and toughness

- Used in polyurethanes, polyureas, and thermoplastic polyamide adhesives

- Salts may be formed for use in cutting fluids

Properties

- Physical Form

- Soluble In

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S002219

- Principal

Storage & Handling

- Handling Information

At temperatures of 75-100°F (24-38°C) Tanks, Lines, valves Carbon steel Pumps Carbon steel Heat exchange surfaces Stainless steel Hoses Stainless steel, polyethylene, polypropylene, and TEFLON®

Gaskets, packing Polypropylene or TEFLON® (elastomers such as neoprene, Buna N, and VITON® should be avoided)

Atmosphere Nitrogen or dry air At temperatures above 100°F (38°C) Tanks Stainless steel or aluminum Lines, Valves Stainless steel Pumps Stainless steel or Carpenter 20 equivalent Atmosphere Nitrogen - ZHENGDA® ® ZD-140 Amine-terminated Polyether may be stored under air at ambient temperatures for extended periods.A nitrogen blanket is suggested for all storage, however, to reduce the effect of accidental exposure to high temperatures and to reduce the absorption of atmospheric moisture and carbon dioxide. It should be noted that pronounced discoloration is likely to occur at temperatures above 140°F (60°C), whatever the gaseous pad.

- Cleanout of lines and equipment containing ZHENGDA® ZD-140 Amine-terminated Polyether can be accomplished using warm water and steam. In the event of spillage of this product, the area may be flushed with water. The proper method for disposal of waste material is by incineration with strict observance of all federal, state, and local regulations.

Other

- ADR/RID/ADN Proper Shipping Name

- Corrosive liquid, N.O.S. (polyether amine zd-140)

- ADR/RID/ADN UN Number

- UN1760

- Appearance

- Colorless to pale yellow liquid with slight haze permitted

- Appearance (SDS)

- Spray-dried, hygroscopic fine powder

- Color (SDS)

- Colorless or transparent

- Dust Explosion Class (SDS)

- St d

- IATA/ICAO Proper Shipping Name

- Corrosive liquid, N.O.S. (polyether amine zd-140)

- IATA/ICAO UN Number

- UN1760

- IMO/IMDG Proper Shipping Name

- Corrosive liquid, N.O.S. (polyether amine zd-140)

- IMO/IMDG UN Number

- UN1760

- Item Number

- Miscible in (SDS)

- Water

- Odor (SDS)

- Ammonia like

- Other Hazards

- The substance is not PBT/vPvB.

- Temperature Control

- No

- USA/DOT Proper Shipping Name

- Corrosive liquid, N.O.S. (polyether amine)

- USA/DOT UN Number

- UN1760

- Chemical Properties

Value Units Test Method / Conditions Amine Hydrogen Equivalent Weight 115.0 g/eq g/eq Equivalent Weight 230.0 g/eq g/eq Isocyanates Free Amine Content 4.0-4.6 meq/g meq/g pH 11.6 - 5% Aqueous Solution - Optical Properties

Value Units Test Method / Conditions Color Scale max. 50.0 Pt-Co Pt-Co Refractive Index 1.4482 - nD20 - Physical Properties

Value Units Test Method / Conditions Density 8.1 lb/gal lb/gal At 25°C Flash Point 163.0 °C °C Pensky-Martens Closed Cup (PMCC) Vapor Pressure 1.0 - At 165°C Vapor Pressure 10.0 - at 193°C Viscosity 22.0 cSt cSt At 25°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) 230.0 °C °C Deflagration Index (SDS) 140.0 bar.m/s bar.m/s Density (SDS) 8.1 lb/gal lb/gal At 25°C Density (SDS) 0.4-0.7 g/mL g/mL Explosive Pressure Rise Rate (SDS) 9.9 % % Flash Point (SDS) 163.0 °C °C Flash Point (SDS) 163.0 °C °C Pensky-Martens Closed Cup (PMCC) Ignition Energy (SDS) min. 30.0 MJ MJ Initial Boiling Point (SDS) 232.0 °C °C Initial Boiling Point (SDS) 232.0 °C °C At 1013.25 Hpa Log Partition Coefficient (Log Pow) (SDS) 1.34 - at 25°C Maximum Explosion Pressure (SDS) 0.9 MPa MPa 7.1 bar Minimum Explosible Concentration (SDS) 60.0 - Minimum Ignition Temperature (SDS) 460.0 °C °C Minimum Thickness for Self Ignition (SDS) 120.0 - at 100°C Minimum Thickness for Self Ignition (SDS) 9.0 - at 200°C Minimum Thickness for Self Ignition (SDS) 5.0 - at 330°C Primary Amine Content (SDS) min. 97.0 % % Relative Density (SDS) 0.972 - at 25°C Total Amine Content (SDS) 4.1-4.7 meq/g meq/g Vapor Pressure (SDS) 1.0 - At 165°C Vapor Pressure (SDS) 10.0 - at 193°C Viscosity (SDS) 22.0 cSt cSt at 25°C Water Activity (SDS) 0.1-0.4 - Water Content (SDS) max. 0.25 % % pH (SDS) 11.6 - 5% Aqueous Solution - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 730.0 -