Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Chemical Name

- Country of Origin

- Function

- Filler

- Industrial Additives Functions

- Plastics & Elastomers Functions

- Product Code

- MITM12254

- Single Ingredient

- Yes

- Synonyms

- Glass, oxide, chemicals, Oxide glass chemicals, Glass Fiber

- Technologies

- Product Families

Features & Benefits

- Industrial Additives Features

- Labeling Claims

- Materials Features

- Product Benefits

- Successfully and predictably reduce the control fluid density.

- Incompressible and more homogeneous control fluid properties compared to aerated systems.

- Eliminate the need for specialized equipment used in foamed cement

- Compatible with both water and oil based systems

- More economical and allow a greater density reduction window than synthetic oils

- Light: When synthetic oils are used as base fluid, densities as low as 0.66 kg/l can be achieved.

- Tiny: 3M™ Glass Bubbles HGS19K46 remain in the fluid when circulating through solids control equipment, including shale shakers, hydrocyclones and centrifuges.

- Tough: Resistant to shear and impact forces when circulating through bit nozzles and impacting formation walls.

- Offer the potential for higher performance through increased rate of penetration

- Reduce your cost through reconditioning and reuse of the lightweight fluid.

Applications & Uses

- Composites End Use

- Industrial Additives End Use

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

Properties

- Physical Form

Regulatory & Compliance

Technical Details & Test Data

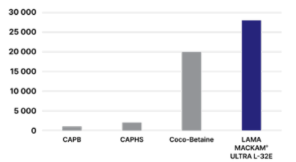

- Effective Densities at Pressure Graph

Safety & Health

- Safety Information

- Select and use eye/face protection to prevent contact based on the results of an exposure assessment and safety glasses with side shields are recommended.

- Wear respiratory protection if ventilation is inadequate to prevent overexposure. An exposure assessment may be needed to decide if a respirator is required. If a respirator is needed, use respirators as part of a full respiratory protection program. Based on the results of the exposure assessment, select from the following respirator type to reduce inhalation exposure: Half facepiece or full facepiece air-purifying respirator suitable for particulates.

- Provide local exhaust ventilation at transfer points. Use general dilution ventilation or local exhaust ventilation to control airborne exposures to below relevant Exposure Limits or control dust. If ventilation is not adequate, use respiratory protection equipment.

Principal Information

- Group Principal Number

- S002409

- Principal

Storage & Handling

- Storage Information

Ideal storage conditions include unopened cartons in a dry and temperature-controlled warehouse. Extended exposure of 3M™ Glass Bubbles HGS19K46 boxes to high humidity and conditions susceptible to condensation may result in some amount of caking of the 3M™ Glass Bubbles.

Other

- Color (SDS)

- White

- Odor (SDS)

- Odorless

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 9.2-9.5 - - Physical Properties

Value Units Test Method / Conditions Density 0.57-0.63 g/cm³ g/cm³ Flotation 90.0 % % Packing Factor 57.0-63.0 - Particle Size 15.0 µm µm 10th% Particle Size 30.0 µm µm 50Th Percentile Particle Size 55.0 µm µm 90Th Percentile Particle Size 20.0 µm µm D50 Sieve Fractionation (Through) 12.0 % % Sieve Fractionation (Through) 20.0 % % D50 Sieve Fractionation (Through) 30.0 % % D90 - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (SDS) 0.25-0.63 g/cm³ g/cm³ Softening Point (SDS) min. 600.0 °C °C Specific Gravity (SDS) 0.25-0.63 - Volatile Content (SDS) max. 0.5 %(W/W) %(W/W) - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d - Thermal Properties

Value Units Test Method / Conditions Thermal Conductivity 0.2 W/m·K W/m·K at 21°C