Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Code

- MITM04868

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Application Area

- Application Method

- Compatible Polymers & Resins

- Markets

- Applications

- Application and Usage Information

- Product Application

- Carburetor Shafts

- Paper handling equipment

- Carburetor links and levers

- Domestic appliance components

- Business machine parts

- Coil coating

- Usage Information

- Surface Preparation

- Substrates must be dry and free of contaminants (dirt, grease, powder, other residues) before application of BBONDERITE® S-FN 334. Excellent results can be obtained without pretreatment. However, for maximum wear characteristics, the following pretreatments are recommended: heat stable phosphate coating* or grit blasting for steel; grit blasting or heat stable conversion coating for aluminum.

- Mixing

- BONDERITE® S-FN 334 is supplied ready for use, but it should be mixed thoroughly by stirring. For best results, use a low-speed propeller type mixer. Do not vortex or agitate violently, as air entrapment or foaming may cause separation of solids.

- Application

- BONDERITE® S-FN 334 is normally spray applied. An external atomizing type gun using a MBC #30 nozzle is recommended. Optimum coating thickness is 0.001 inch (25.4 m). Use only acheson SB 3 solvent for cleanup. Incompatible solvents will cause gun blockage.

- Overcoating

- BONDERITE® S-FN 334 can be overcoated for repair purposes without removing the entire original film. Sand lightly or use steel wool to feather the edges of the area to be repaired. Light abrasion of the surrounding areas is also recommended for maximum adhesion. Then apply BONDERITE S-FN 334 ACHESON (known as EMRALON 334), using the same spray procedure as for the initial application.

- Curing

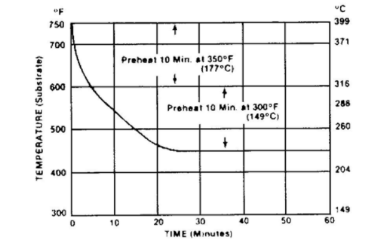

- BONDERITE® S-FN 334 may be cured by exposure to any of the time/temperature conditions indicated on the following graph:

- It is essential that the high boiling solvents in BONDERITE® S-FN 334 be removed gradually before the cure is completed or the coating will be marred by blisters. Remove the solvent gradually by preheating the coating for ten minutes at 149°C or 177°C before curing, as indicated.

- BONDERITE® S-FN 334 may be cured by exposure to any of the time/temperature conditions indicated on the following graph:

- Surface Preparation

- Product Application

Properties

- Physical Form

Technical Details & Test Data

- Curing Properties

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000218

- Principal

Storage & Handling

- Storage and Shelf Life Information

- Shelf life for this product is 2 years from date of qualification under original seal at 24°C. Prolonged storage at temperatures higher than 27°C is not recommended. Keep container tightly closed when not in use. Store in a cool, well ventilated area. Keep away from heat, sparks, and open flame. Protect material from direct sunlight. Ground and bond containers when transferring materials. Empty containers may retain hazardous properties.

Other

- Color

- Black

- Color (SDS)

- Black

- IATA/ICAO Proper Shipping Name

- Flammable liquid, N.O.S. (methoxy propyl acetate)

- IATA/ICAO UN Number

- UN 1993

- IMO/IMDG Proper Shipping Name

- Flammable liquid, N.O.S. (methoxy propyl acetate)

- IMO/IMDG UN Number

- UN 1993

- Item Number

- Odor (SDS)

- Solvent

- Temperature Control

- Yes

- USA/DOT Proper Shipping Name

- Combustible liquid, N.O.S. (methoxy propyl acetate)

- USA/DOT UN Number

- NA 1993

- Application Information

Value Units Test Method / Conditions Application Temperature 260.0 °C °C Application Temperature 204.0-232.0 °C °C continuous - Material Composition

Value Units Test Method / Conditions Solid Content 30.0 % % by weight Volatile Organic Compounds (VOC) 6.6 lb/gal lb/gal - Mechanical Properties

Value Units Test Method / Conditions Abrasion Loss 25.3 % % Taber Abrasion Test at CS-10 Wheel, weight loss per 1000 cycles Coefficient of Friction 0.08 - as kinetic Coefficient of Friction 0.07 - as static Wear Resistance 280000.0 Cycles Cycles Modified Hartmann tube at 180 lb load, cycles - Physical Properties

Value Units Test Method / Conditions Coverage 300.0 ft²/gal ft²/gal at 0.001 inch, 7.4 sq meters/liter, 25.4 μm Density 9.4 lb/gal lb/gal Flash Point 54.0 °C °C Storage Temperature max. 90.0 °F °F - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) min. 35.0 °C °C Evaporation Rate (SDS) 1.0 % % Butyl Acetate=1 Flash Point (SDS) 54.0 °C °C Pensky-Martens Closed Cup (PMCC) Lower Explosion Limit (SDS) 1.5 % % Relative Vapor Density (SDS) 1.0 - Air=1 Specific Gravity (SDS) 1.128-1.152 - Upper Explosion Limit (SDS) 10.0 % % Vapor Pressure (SDS) 0.3 mm Hg mm Hg Viscosity (SDS) 600.0-1100.0 cPs cPs Volatile Organic Content (VOC) (SDS) 790.0 g/L g/L - Shelf Life & Stability

Value Units Test Method / Conditions Salt Spray Resistance 500.0 h h ASTM B117 at 5% Concentration Shelf Life 2.0 yr yr