Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Chemical Name

- Fluids & Lubricants Functions

- Function

- Dispersant, Reclaiming Agent

- Plastics & Elastomers Functions

- Product Code

- MITM14581

- Single Ingredient

- Yes

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

- Labeling Claims

Applications & Uses

- Applicable Processes

- Base Chemicals End Uses

- Fluids & Lubricants End Use

- Fluids & Lubricants Type

- Markets

- Applications

- Product Applications

- Surfactants - The largest industrial use for nonylphenol is in the manufacture of nonionic surfactants. These ethoxylated nonylphenol surfactants have good chemical stability and excellent wetting, emulsifying and detergent properties.

- TNPP - Nonylphenol is reacted with phosphorus trichloride to produce trisnonylphenyl phosphite, which is common antioxidant for a wide range of polymer systems.

- Phenolic Resins - Nonylphenol reacts with aldehydes to yield phenolic resins. When used with other phenols, even in small quantities, it makes the phenolic resins more water resistant, more soluble in oil, and improves electrical properties.

- Rubber Chemistry - Nonylphenol sulfide has been used in the past as a reclaiming agent for synthetic rubber.

- PVC - A variety of nonylphenol derivatives have uses as polyvinyl chloride plasticizer intermediates. These intermediates include nonylphenol benzoate, nonylphenol alkanesulfonates and nonylcyclohexanol.

- Epoxy Resins - Nonylphenol can be used in an epoxy resin hardener.

- Miscellaneous - Other possible fields of application for nonylphenol are in pharmaceuticals, corrosion inhibitors, dyestuffs, ore floatation agents, insecticides, bactericides, chemical stabilizers, and the leather industry. Overbased calcium salt nonylphenol can also be used as a dispersant in hydraulic fluid and motor oil.

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000244

- Principal

Other

- Appearance

- Clear substantially free from suspended matter

- Appearance (SDS)

- Clear

- Color (SDS)

- Colorless to light yellow

- Flammability Class (SDS)

- Combustible IIIB estimated

- Item Number

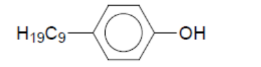

- Molecular Formula (SDS)

- C₁₅H₂₄O

- Odor (SDS)

- Phenolic

- USA/DOT UN Number

- Not Applicable

- Optical Properties

Value Units Test Method / Conditions Color Scale max. 50.0 APHA APHA - Chemical Properties

Value Units Test Method / Conditions Assay 92.62-94.38 % % Para NP Content Hydroxyl Value 240.0-255.0 mg KOH/g mg KOH/g - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d - Physical Properties

Value Units Test Method / Conditions Density 7.9 lb/gal lb/gal At 20°C Moisture Content 1000.0 ppm ppm Molecular Weight 220.0 g/mol g/mol Pour Point 35.0 °F °F Specific Gravity 0.95 - at 25°C Viscosity 1500.0 cPs cPs At 25°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Flash Point (SDS) 294.0 °F °F Pensky-Martens Closed Cup (PMCC) Initial Boiling Point (SDS) 545.0 °F °F Specific Gravity (SDS) 0.95 - Vapor Pressure (SDS) 5.0 mm Hg mm Hg