Enhanced TDS

Identification & Functionality

- Additives Included

- Blend

- Yes

- Chemical Family

- Country of Origin

- Polymer Name

- Product Code

- MITM01775

- Single Ingredient

- No

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Product Applications

- Flexible injected parts

- High performance power trasmission belts

- Silent gears

- Toy component

- Processing Information

- Injection Molding

- Film Extrusion

- Profile Extrusion

- Extrusion

- Transfer Molding

- Casting

- Thermoforming

Properties

Technical Details & Test Data

- Technical Data

- Typical melt temperature (Min / Recommended / Max) : 180°C / 210°C / 240°C.

- Typical mold temperature : 10 – 30°C.

- Drying time and temperature (only necessary for bags opened for more than two hours) : 4-8 hours at 55-65°C

- Technical Data

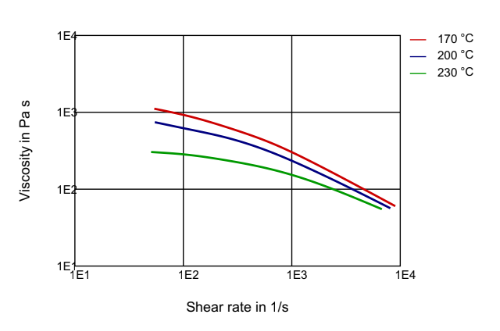

Viscosity-shear Rate

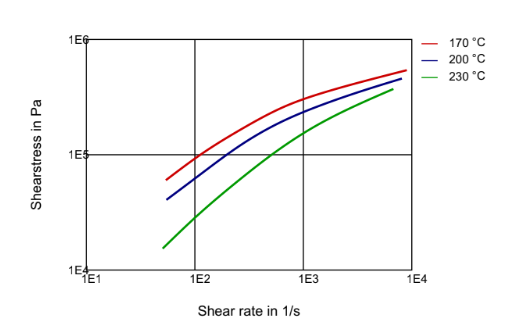

Shear Stress-Shear Rate

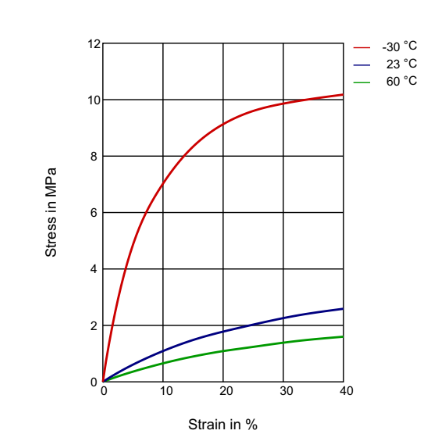

Stress-strain

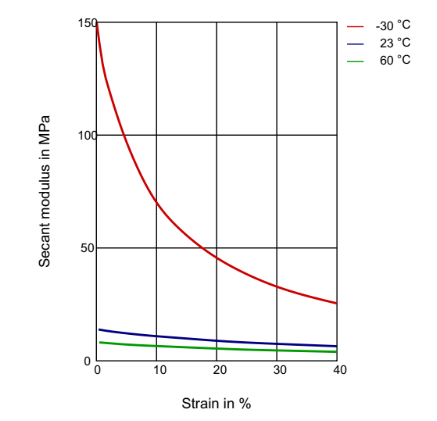

Secant Modulus-strain

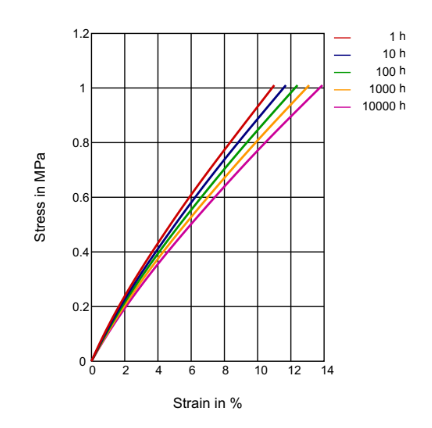

Stress-strain (Isochronous) 23°C

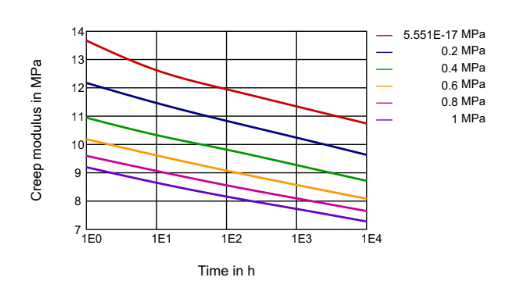

Creep Modulus - Time 23°C

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Color (SDS)

- Colorless to slightly yellow

- Item Number

- Odor (SDS)

- Odorless

- Other Hazards

- Processing may release vapors and/or fumes which cause eye, skin and respiratory tract irritation, Prolonged or repeated exposure may cause: headache, drowsiness, nausea, weakness, (severity of effects depends on extent of exposure).

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Electrical Properties

Value Units Test Method / Conditions Comparative Tracking Index 600.0 - IEC 60112 condensed Dielectric Constant 6.0 - IEC 60250 at 100 Hz, dry Dielectric Strength 33.5 kV/mm kV/mm IEC 60243-1 dry basis Dissipation Factor 0.031 tan δ tan δ IEC 60250 1MHz, dry Dissipation Factor 0.0434 tan δ tan δ IEC 60250 at 100 Hz, dry Surface Resistance 3000000000000.0 Ω Ω IEC 60093 condensed Volume Resistivity 32000000000.0 Ω-cm Ω-cm IEC 60093 1MHz, dry - Mechanical Properties

Value Units Test Method / Conditions Compression Set 22.0 - ISO 815 at 23°C, 24 h, Dry Hardness 25.0 - Hardness 82.0 - Shore Durometer Scale Hardness 25.0 - ISO 868 Strain at Break min. 50.0 - ISO 527-1 Dry, at break Strain at Break min. 300.0 - ISO 527-1 dry, thermoplastic elastomer, at break Stress 6.0 MPa MPa ISO 527-1 dry, at 100% elongation Stress 2.0 MPa MPa ISO 527-1 dry, at 10% elongation Stress 4.0 MPa MPa ISO 527-1 dry, at 50% strain Stress 4.0 MPa MPa ISO 527-2 condensed, at 50% strain Stress at Break 39.0 MPa MPa ISO 527-1 dry, thermoplastic elastomer, at break Tear Strength 50.0 kN/m kN/m ISO 34-1 dry basis Tensile Modulus 19.0 MPa MPa ISO 527-1 dry basis Tensile Modulus 18.0 MPa MPa ISO 527-2 condensed Volume Loss 64.0 mm³ mm³ ISO 4649 Dry, Abrasion Resistance - Physical Properties

Value Units Test Method / Conditions Density 830.0 - dry, liquid Density 1000.0 - ISO 1183 condensed Density 1000.0 - ISO 1183 dry basis Glass Transition Temperature (Tg) -65.0 °C °C ISO 11357-1 at 10°C/min, dry Humidity Absorption 0.4 % % ISO 62 dry basis Load/Unload Temperature 46.0 °C °C ISO 75-1 at 0.45 MPa, dry, deflection under load Load/Unload Temperature 46.0 °C °C ISO 75-2 at 0.45 MPa, dry, deflection under load Melting Point 144.0 °C °C ISO 11357-1 at 10°C/min Mold Shrinkage 0.8 - ISO 2577 normal, dry Mold Shrinkage 0.5 - ISO 2577 parallel, dry Mold Shrinkage 0.8 - ISO 294-4 normal, dry Mold Shrinkage 0.5 - ISO 294-4 parallel, dry Softening Point 77.0 °C °C ISO 306 at 50°C/h, 50N, dry Storage Temperature max. 140.0 °F °F Water Absorption 1.2 % % ISO 62 dry basis - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Decomposition Temperature (SDS) 572.0-662.0 °F °F - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 2.0 - - Thermal Properties

Value Units Test Method / Conditions Coefficient of Thermal Expansion 0.00021 /K /K ISO 11359-1 parallel, dry Specific Heat 2800.0 J/kg.K J/kg.K dry, of melt Thermal Conductivity 0.18 -