Enhanced TDS

Identification & Functionality

- Additives Included

- Blend

- Yes

- Chemical Family

- Country of Origin

- Polymer Name

- Product Code

- MITM15140

- Single Ingredient

- No

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Processing Information

Injection Molding, Film Extrusion, Profile Extrusion, Other Extrusion, Transfer Molding, Casting, Thermoforming.

Properties

Technical Details & Test Data

- Technical Data

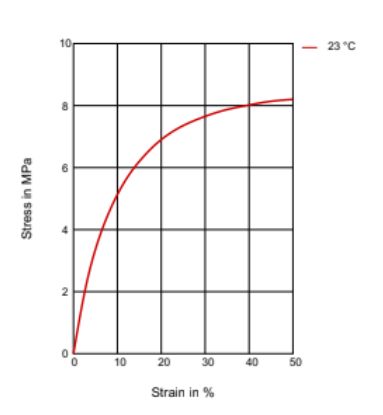

Stess-Strain Diagram:

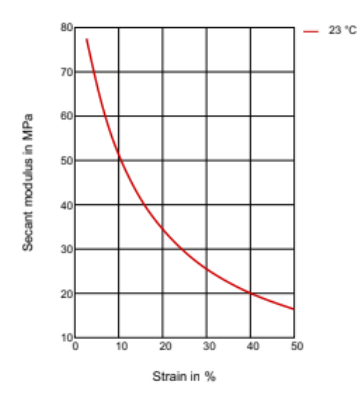

Secant Modulus-Strain Diagram:

Processing Conditions (Injection molding):

- Typical melt temperature (Min / Recommended / Max): 200°C / 240°C / 270°C.

- Typical mold temperature: 10 - 30°C.

- Drying time and temperature (only necessary for bags opened for more than two hours): 4-8 hours at 60-70°C.

Processing Conditions (Extrusion):

- Typical melt temperature (Min / Recommended / Max): 210°C / 220°C / 230°C.

- Drying time and temperature (only necessary for bags opened for more than two hours): 4-8 hours at 60-70°C.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Color (SDS)

- Colorless to slightly yellow

- Item Number

- Odor (SDS)

- Odorless

- Other Hazards

- Processing may release vapors and/or fumes which cause eye, skin and respiratory tract irritation, Prolonged or repeated exposure may cause: headache, drowsiness, nausea, weakness, (severity of effects depends on extent of exposure).

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Carbon Content 45.0 % % ASTM D6866 - Mechanical Properties

Value Units Test Method / Conditions Hardness 39.0 Shore D Shore D Hardness 39.0 Shore A Shore A ISO 868 Strain at Break min. 300.0 % % ISO 527-1 at break thermoplastic elastomer, dry Strain at Break min. 50.0 % % ISO 527-2 at break, condensed Stress 8.2 MPa MPa ISO 527-2 at 50% strain, condensed Stress at Break 45.0 MPa MPa ISO 527-1 at break thermoplastic elastomer, dry Tensile Modulus 75.0 MPa MPa ISO 527-2 condensed - Physical Properties

Value Units Test Method / Conditions Density 1030.0 kg/m³ kg/m³ ISO 1183 condensed Density 1030.0 kg/m³ kg/m³ ISO 1183 dry basis Humidity Absorption 0.5 % % ISO 62 dry basis Melting Point 148.0 °C °C ISO 11357-1 at 10°C/min Mold Shrinkage 0.7 % % ISO 2577 normal, dry Mold Shrinkage 0.6 % % ISO 2577 parallel, dry Mold Shrinkage 0.7 % % ISO 294-4 normal, dry Mold Shrinkage 0.6 % % ISO 294-4 parallel, dry Storage Temperature max. 140.0 °F °F Water Absorption 1.3 % % ISO 62 dry basis - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Decomposition Temperature (SDS) 572.0-662.0 °F °F Lower Explosion Limit (SDS) 45.0 % % at 85⁰C Melting Point (SDS) 383.0 °F °F - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 2.0 yr yr