Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Chemical Name

- Country of Origin

- Industrial Additives Functions

- Plastics & Elastomers Functions

- Product Code

- MITM16032

- Single Ingredient

- Yes

- Synonyms

- Glass, oxide, chemicals, Oxide glass chemicals, Glass Fiber

- Technologies

- Product Families

Features & Benefits

- Industrial Additives Features

- Labeling Claims

- Materials Features

- Product Features

- Successfully and predictably reduce the control fluid density

- Incompressible and more homogeneous control fluid properties compared to aerated systems

Applications & Uses

- Applicable Processes

- Industrial Additives End Use

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Processing Information

3M™ Glass Bubbles HGS4K28 breakage may occur if the product is improperly processed. To minimize breakage, avoid high shear processes, point contact shear such as gear pumps or 3-roll mills, and processing pressures above the strength test pressure for each product.

Properties

- Physical Form

- Stability Data

Appreciable changes in 3M™ Glass Bubbles HGS4K28 properties may occur above 1112°F (600°C) depending on temperature and duration of exposure.

Regulatory & Compliance

Technical Details & Test Data

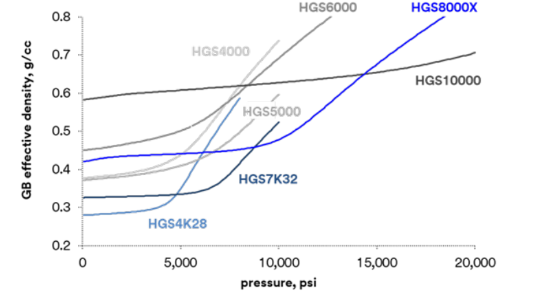

- Density vs Pressure Graph

3M™ Glass Bubbles K15 effective densities at pressure

- Technical Data

3M™ Glass Bubbles HGS4K28 in drilling, completion and work-over fluids

- Eliminate the need for specialized equipment used in foamed cement

- Compatible with both water and oil based systems

- More economical and allow a greater density reduction window than synthetic oils

- Helps achieve and maintain the target density throughout the drilling operation:

- Light - when synthetic oils are used as base fluid, densities as low as 5.5 lb/gal (0.66 kg/l) can be achieved.

- Tiny - 3M™ Glass Bubbles HGS8000X and 3M™ Glass Bubbles HGS4K28 remain in the fluid when circulating through solids control equipment, including shale shakers, hydrocyclones and centrifuges.

- Tough - resistant to shear and impact forces when circulating through bit nozzles and impacting formation walls.

- Offer the potential for higher performance through increased rate of penetration (ROP).

- Reduce your cost through reconditioning and reuse of the lightweight fluid.

3M™ Glass Bubbles HGS4K28 in cementing:

- Consistency batch-to-batch, location-to-location

- Broad effective density at any pressure

- Improved density reduction capacity – cement slurry density values below 9.0 lb/gal (1.1 kg/l) have been achieved.

- Low-density, high-strength 3M Glass Bubbles HGS Series are lighter and stronger and help achieve higher strength-to-weight cement designs.

- Light weight cement slurries made with 3M Glass Bubbles HGS series help prevent problems associated with fluid loss/lost circulation such as reduced top of cement (TOC) and thus the need for remedial squeeze. Additional benefits include the potential for:

- Reduced Wait-On-Cement (WOC)

- Reduced need for multi-staging

Safety & Health

- Safety Precautions

For worker protection, please follow your company’s procedures for safety and proper PPE, and consider the following:

- Select and use eye/face protection to prevent contact based on the results of an exposure assessment. Safety Glasses with side shields are recommended.

- Wear respiratory protection if ventilation is inadequate to prevent overexposure. An exposure assessment may be needed to decide if a respirator is required. If a respirator is needed, use respirators as part of a full respiratory protection program. Based on the results of the exposure assessment, select from the following respirator type(s) to reduce inhalation exposure: Half facepiece or full facepiece air-purifying respirator suitable for particulates. (For additional information about personal protective equipment, refer to the product Safety Data Sheet.)

- Provide local exhaust ventilation at transfer points. Use general dilution ventilation and/or local exhaust ventilation to control airborne exposures to below relevant Exposure Limits and/ or control dust. If ventilation is not adequate, use respiratory protection equipment.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S002409

- Principal

Storage & Handling

- Storage Conditions

Storage: Ideal storage conditions include unopened cartons in a dry and temperature-controlled warehouse.

Extended exposure of 3M™ Glass Bubbles HGS4K28 boxes to high humidity and/or conditions susceptible to condensation may result in some amount of “caking” of the 3M™ Glass Bubbles HGS4K28. To minimize the potential for caking and thereby maximize storage life, the following suggestions are offered:

- Carefully re-tie opened bags immediately after use.

- If the polyethylene bag is punctured during shipping or handling, seal the hole as soon as possible or insert the contents into an undamaged bag.

- During hot and/or humid months, store boxes in the driest, coolest space available.

If controlled storage conditions are unavailable, carry a minimum inventory and process on a first in/ first out basis.

Handling: Due to the low weight and small particle size of 3M™ Glass Bubbles HGS4K28, dusting may occur while handling and processing. To minimize the dusting potential during handling,

consider the following:- Do not open 3M™ Glass Bubbles HGS4K28 packages until ready to use.

- Upon opening, have an air siphon near the opening to pull away airborne particles. (Dust collection equipment may be required – check local OSHA and other applicable regulations.)

- Remove 3M™ Glass Bubbles HGS4K28 with a suction “wand” (with slight positive pressure aeration) and transfer to a closed mixing tank inside fully contained piping. If a closed mixing tank is not available, use dust collection equipment as close as practical to the point of entry. Pneumatic conveyor systems have been used successfully to transport 3M™ Glass Bubbles HGS4K28 without dusting from shipping containers to batch mixing equipment. Equipment vendors should be consulted for recommendations.

- Static eliminators should be used to prevent static buildup.

Other

- Appearance

- White to the unaided eye

- Color (SDS)

- White

- Item Number

- Odor (SDS)

- Odorless

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions Alkalinity max. 0.5 meq/g meq/g pH 9.2-9.5 - - Mechanical Properties

Value Units Test Method / Conditions Isostatic Crush Strength 4000.0 psi psi Nitrogen Isostatic Crush Strength, 80% Minimum Fractional Survival, 90% Target Fractional Survival, in glycerol - Physical Properties

Value Units Test Method / Conditions Density 0.25-0.31 g/cm³ g/cm³ Density 0.28 g/cm³ g/cm³ Nominal Particle Size 30.0 µm µm D50 Particle Size 45.0 µm µm Internal Method 90% vol. Particle Size 20.0 µm µm Internal Method by volume, 10% distribution Particle Size 30.0 µm µm Internal Method D50, by volume Solubility in Mud Acid 0.9995 %(W/W) %(W/W) - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (SDS) 0.25-0.63 g/cm³ g/cm³ Softening Point (SDS) min. 600.0 °C °C Specific Gravity (SDS) 0.25-0.63 - Volatile Content (SDS) max. 0.5 %(W/W) %(W/W) - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 2.0 yr yr