Enhanced TDS

Identification & Functionality

- Chemical Family

- Function

- Thickener

- Industrial Additives Functions

- Product Code

- MITM11264

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Performance Highlights

- ACRYSOL DR-300 thickener provides application and "feel" properties very similar to those of medium and high-molecular-weight cellulosic thickeners with better leveling, sag resistance, and resistance to roller spattering in most formulations.

- A comparison of a high-molecular-weight cellulosic thickener and ACRYSOL

DR-300 in a 48% PVC/30% VS all-acrylic exterior formulation based on PRIMAL™ SF-016 ER emulsion illustrates the similarity in the key rheology properties they provide

Rheological properties 1% ACRYSOL™ DR-300 Viscosities after production 0,8 ICI Viscosities after production 108 KU Viscosities after production 27700 Brookfield Sp 4/6 rpm

Viscosities after equilibrium 0,7 ICI, 48 hrs Viscosities after equilibrium 110 KU, 48 hrs Viscosities after equilibrium 29800 Brookfield Sp 4/6 rpm, 48 hrs

Viscosities after heat aging 0,5 ICI, 10 days at 60°C

Viscosities after heat aging 108 KU, 10 days at 60°C

Viscosities after heat ageing 24800 Brookfield Sp 4/6 rpm, 10 days at 60°C

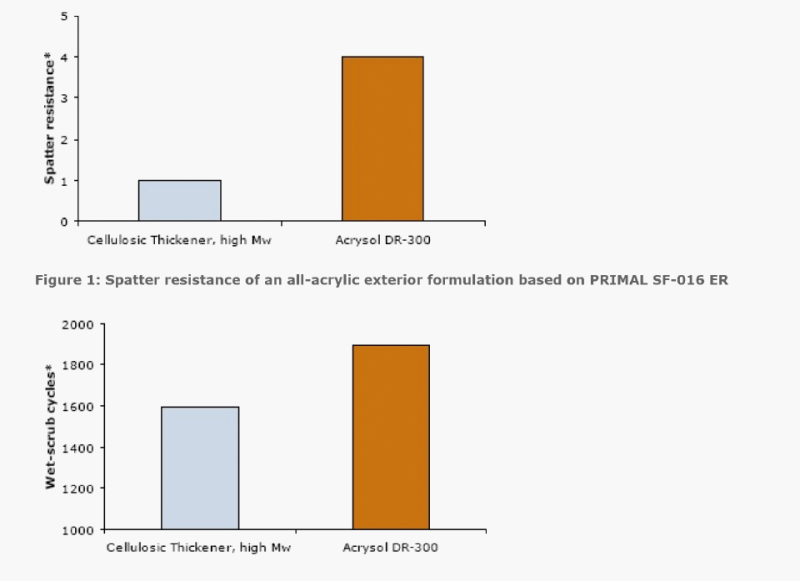

Spatter resistance Excellent Water resistance Excellent - Apart from the achieved benefit of lower formulated cost, Figure 1 and 2 show the superior resistance to roller spattering and the enhanced water resistance of ACRYSOL DR-300. In general, traditional synthetic thickeners based on acrylate increase the water sensitivity and therefore decrease the scrub resistance.

- The new technology generation provides superior scrub resistance compared to traditional synthetic thickeners.

Figure 2: Water resistance of an all-acrylic exterior formulation based on PRIMAL SF-016 ER

- Product Characteristics

- Good water resistance: Exterior durability

- Low-viscosity liquid: Easy to handle and incorporate during manufacturing

- Good flow/sag balance: Thicker films; good appearance

- Good paint consistency and stability: Thick, creamy "in-can" appearance with stable viscosity

- Synthetic: Resistant to microbial attack

- Excellent thickening efficiency, lower formulated cost

Applications & Uses

- Markets

- Applications

- Formulation Information

- When substituting any synthetic associative thickener for a cellulosic agent, the proper choice of dispersant, co-solvent, and surfactant is critical to achieving maximum performance properties and cost savings. While pure polyacid dispersants like OROTAN™ N-4045 are showing excellent compatibility with the DR-Technology, the usage of a hydrophobic copolymer dispersant is recommended with ACRYSOL DR-300 because of the superior exterior durability.

- Therefore OROTAN 731-A-ER, at a level of 0.80% solids on titanium dioxide/extender solids, has consistently promoted efficiency and general application performance. For optimum water resistance properties, the most suitable dispersant is OROTAN 165.

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000005

- Principal

Other

- Appearance

- Milky white liquid

- Color (SDS)

- Milky white

- Item Number

- Odor (SDS)

- Acrylic like

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 4.0-6.0 - as supplied - Material Composition

Value Units Test Method / Conditions Solid Content 17.5 % % - Physical Properties

Value Units Test Method / Conditions Density 1.04 g/cm³ g/cm³ at 25°C Viscosity 2000.0-7500.0 cPs cPs Brookfield Viscometer as supplied - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C at 760 mmHg, water Boiling Point (SDS) 100.0 °C °C Evaporation Rate (SDS) max. 1.0 % % Butyl Acetate=1 Evaporation Rate (SDS) max. 1.0 % % Butyl acetate = 1, water Melting Point (SDS) 0.0 °C °C Melting Point (SDS) 0.0 °C °C Water Relative Vapor Density (SDS) max. 1.0 - Air = 1, Water Relative Vapor Density (SDS) max. 1.0 - Air=1 Specific Gravity (SDS) 1.04 - Water = 1 Viscosity (SDS) max. 5000.0 mPa.s mPa.s Volatile Content (SDS) 81.0-84.0 % % pH (SDS) 4.0-6.0 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d