Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Function

- Photoinitiator

- Product Code

- MITM00107

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Ink & Toner End Applications

- Markets

- Applications

Properties

- Physical Form

Technical Details & Test Data

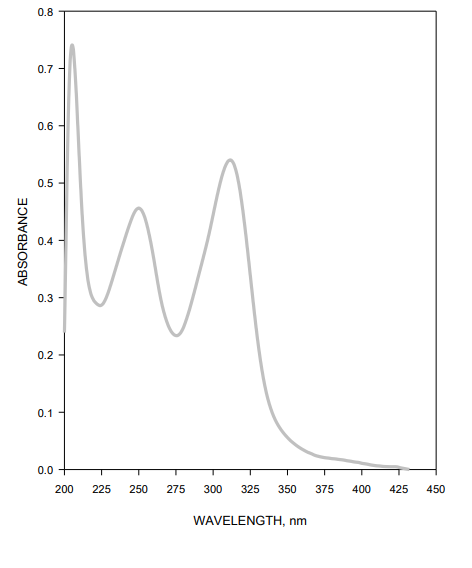

- UV Absorbance Spectra

Typical uv absorbance spectra of additol dx

0.001 concentration in methanol

Safety & Health

- Safety Precautions

Avoid contact with eyes, skin, and clothing. Direct contact with this material may cause moderate eye and skin irritation. Wash thoroughly after handling. Use with adequate ventilation. Keep container closed.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage Conditions

- ADDITOL® DX has a maximum recommended storage temperature of 38°C (100°F). Do not store in direct sunlight. Containers should be kept closed and away from oxidizing agents, acids, alkalis, and x-ray or ultraviolet radiation. Over time, ADDITOL® DX may show signs of crystallization or precipitation. The efficacy of the photoinitiator blend will be affected by this crystallization. Thus, it will be necessary to treat the ADDITOL® DX to redissolve the crystals.

- Crystals typically begin to form 3-6 months after the last heat treatment of the ADDITOL® DX. These crystals may be difficult to see. They may be transparent and needle-like, and tend to accumulate at the bottom of a container. If crystals are noted, the container of ADDITOL® DX should be heated at 60°C for some period of time (detailed below). The heated container should then be mixed by shaking or rolling to ensure that the crystals are redissolved. Ovens or hotboxes are recommended methods of heating. Heating tapes should not be used.

- The ADDITOL® DX will be stable to crystallization for at least 3 months after this heat treatment. Multiple treatments of the same container are acceptable. Once the crystals are redissolved, the efficacy of the photoinitiator blend is restored. No detrimental effects on performance have been noted after heat treatment.

Suggested Heat Treatment For ADDITOL® DX

CONTAINER SIZE TEMPERATURE TIME 1 quart or smaller 60°C 8 hours 1-5 gallons 60°C 12-24 hours 1 drum 60°C 24-48 hours

Other

- Appearance

- Clear amber liquid

- Appearance (SDS)

- Liquid

- Color (SDS)

- Color varies

- IATA/ICAO Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- IATA/ICAO Technical name (N.O.S.)

- Aromatic ketones

- IATA/ICAO UN Number

- UN3082

- IMO/IMDG Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- IMO/IMDG Technical name (N.O.S.)

- Aromatic ketones

- IMO/IMDG UN Number

- UN3082

- Item Number

- Odor (SDS)

- Ester acrylate

- Other Hazards

- Not applicable

- Oxidizing Properties (SDS)

- None

- Protect from Freezing

- Yes

- TDG Canada Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- TDG Canada Technical name (N.O.S.)

- Aromatic ketones

- TDG Canada UN Number

- UN3082

- Temperature Control

- No

- USA/DOT Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- USA/DOT Technical name (N.O.S.)

- Aromatic ketones

- USA/DOT UN Number

- UN3082

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) 5.0-10.0 %(W/W) %(W/W) - Optical Properties

Value Units Test Method / Conditions Color Scale max. 12.0 Gardner Gardner Gardner Color Scale - Physical Properties

Value Units Test Method / Conditions Density 1.1 g/mL g/mL At 25°C Flash Point min. 100.0 °C °C Viscosity 45.0-85.0 cPs cPs At 25°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (SDS) 1.1 g/cm³ g/cm³ Flash Point (SDS) min. 100.0 °C °C SetaFlash Closed Cup Viscosity (SDS) 55.0-85.0 mPa.s mPa.s at 25°C, low viscous liquid - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d