Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Code

- MITM09323

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Features

- Addonyl® 8073 is a solid high-molecular-weight polyol.

- Addonyl® 8073 is used in rotomolding to prevent the formation of voids and pinholes. Furthermore, it also improves the impact value and the machinability of the obtained cast nylon.

Applications & Uses

- Applicable Processes

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Product Uses

- The reactivity of the polymerizing melt is influenced by various factors. We therefore advise against a concentration of > 2% p.b.w., because otherwise problems with the polymerization may occur.

- The product is easily soluble in molten caprolactam. The caprolactam melt containing the activator is susceptible to oxidation. Thus, we recommend working under inert gas.

Properties

- Physical Form

- Soluble In

Technical Details & Test Data

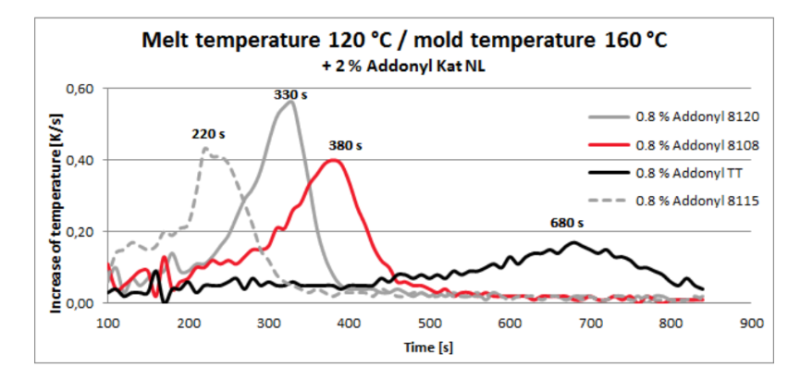

- Reactivity of Various Addonyl® activators

- The following diagram shows the reactivity of various Addonyl® activators, with the same weight dosing, subject to time:

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000008

- Principal

Storage & Handling

- Storage Conditions

- If handled correctly, the product has a shelf-life of at least 24 months.

- A receiving inspection is recommended.

- The product should be stored in a cool, dry place.

- Once opened, containers should be resealed tightly after removal of product.

Other

- Appearance

- Colorless waxy flakes with weak inherent odor

- Color (SDS)

- Colorless

- Item Number

- Odor (SDS)

- Slight characteristic

- Other Hazards

- None known

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Application Temperature 130.0-160.0 °C °C mold Dosage (Use Level) 0.3-2.0 %(W/W) %(W/W) - Chemical Properties

Value Units Test Method / Conditions Hydroxyl Value max. 7.0 mg KOH/g mg KOH/g - Physical Properties

Value Units Test Method / Conditions Melting Point 60.0 °C °C Moisture Content max. 0.5 % % Storage Temperature max. 122.0 °F °F - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Bulk Density (SDS) 400.0-500.0 kg/m³ kg/m³ Decomposition Temperature (SDS) 360.0 °C °C Density (SDS) 1.2 g/cm³ g/cm³ Flash Point (SDS) 240.0 °C °C Closed Cup Flash Point (SDS) 240.0 °C °C DIN 51376 Ignition Temperature (SDS) min. 320.0 °C °C Kinematic Viscosity (SDS) 25.0-35.0 cm²/s cm²/s Log Partition Coefficient (Log Pow) (SDS) max. -1.0 - n-Octanol/Water Melting Point (SDS) 60.0 °C °C Viscosity (SDS) 2700.0-3500.0 mPa.s mPa.s pH (SDS) 5.0-7.0 - pH (SDS) 5.0-7.0 - concentration 10 w/w% - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 24.0 mo mo