Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Function

- Thinner

- Product Code

- MITM13403

- Technologies

- Product Families

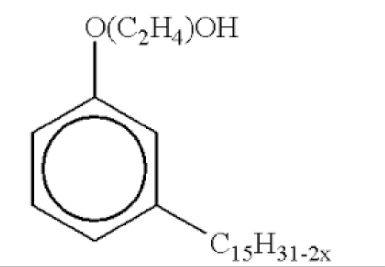

- Chemical Structure

Features & Benefits

Applications & Uses

- Application Method

- Coating End Applications

- Compatible Substrates & Surfaces

- Markets

- Applications

- Product Applications

It is used in combination with liquid Epoxy resins or solid epoxy resin solution. Suitable for making high solids or solvent less coating compositions. Suitable for application with standard one-component airless spray systems, brush and roller. Ideal for marine and protective coatings e.g. structural steel, concrete flooring etc.

Properties

- Physical Form

- Product Properties

Epoxy coating systems cured with AP 8030 present the following features.

- Gives flexibility to coating and good wetting to the substrate.

- High levels of mechanical stability.

- Good adhesion to marginally prepared surfaces.

- Resistance to water.

- Good corrosion resistance in epoxy systems.

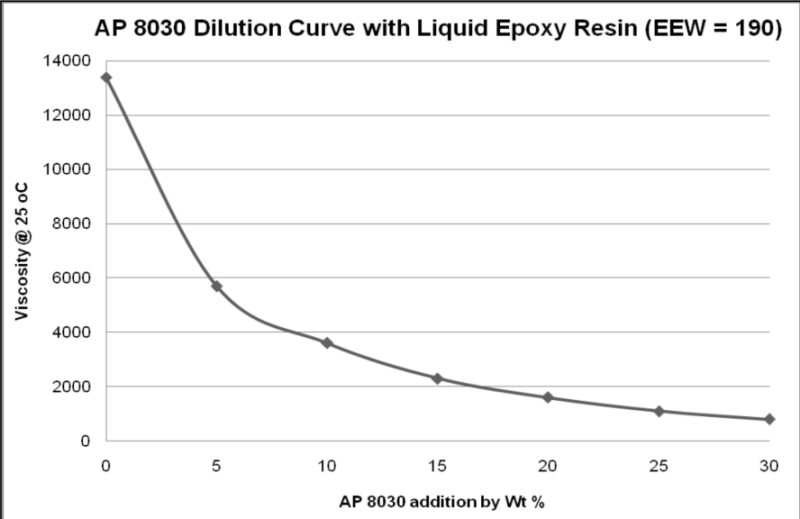

- Reduces viscosity of Epoxy Component.

- Excellent brush and roller application.

Technical Details & Test Data

- Dilution Properties

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S001795

- Principal

Storage & Handling

- Handling Information

Use personal protective equipments and follow industrial hygienic procedures. Recommended to use safety glasses, protective clothing, gloves, & masks suitable for chemical and solvents & their vapor.

- Storage Conditions

AP 8030 should be stored in a dry place, preferably in the sealed original container at temperatures 5 to 30°C. The Product should not be stored exposed to direct sunlight.

- Shelf life: 12 Months (15 to 30°C).

- Hazardous decomposition products: (When in fire) Carbon monoxide, Carbon dioxide, Nitrogen Oxides and other toxic Gases & Vapors.

Other

- Appearance

- Clear yellow color liquid

- Color (SDS)

- Colorless

- Insoluble in (SDS)

- Water

- Item Number

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) max. 20.0 - - Chemical Properties

Value Units Test Method / Conditions Hydroxyl Value 160.0-200.0 mg KOH/g mg KOH/g pH 7.0-9.0 - - Material Composition

Value Units Test Method / Conditions Non-Volatile Content min. 98.0 % % - Optical Properties

Value Units Test Method / Conditions Color Scale max. 14.0 Gardner Gardner Color Scale max. 14.0 - ASTM D1544 - Physical Properties

Value Units Test Method / Conditions Density 0.94-0.96 - ASTM D1475 at 25°C Flash Point min. 120.0 °C °C Viscosity 50.0-120.0 - DIN 53015 at 25°C Viscosity 50.0-120.0 - ISO 12058 at 25°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (SDS) 0.94-0.96 g/cm³ g/cm³ ASTM D1475 at 25°C Flash Point (SDS) min. 150.0 °C °C Viscosity (SDS) 70.0-90.0 - ISO 12058 at 25°C - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 12.0 -