Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Composite Materials Functions

- Function

- Toughness Modifier, Toughener

- Plastics & Elastomers Functions

- Product Code

- MITM16426

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Key Features

High Performance Toughening Agent Tailored for Low Polar Methacrylic Resins

- Methylmethacrylate-Butadiene-Styrene (MBS) core shell

- Tailored for low polar methacrylic resins

- Optimized to the most demanding electronic and additive applications

- Performance without effect on glass transition temperature

Applications & Uses

- Adhesive & Sealant End Applications

- Plastics & Elastomers End Uses

- Dispersion Information

- Clearstrength® XT152 powder can be dispersed in liquid monomers preferably with a medium shear mixer at room temperature.

- Dilution of high core-shell content preparation can be achieved with standard anchor blade homogenization.

- Clearstrength® XT152 powder can also be dispersed via melt extrusion or shear incorporation process.

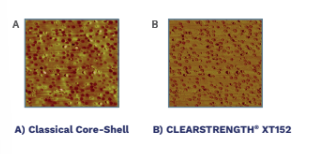

Enhancing compatibility reaching dispersion at the individual core-shell in low polar/ hydrophobic methacrylic systems.

- Product Uses

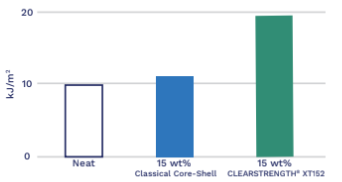

- Clearstrength® XT152 is particularly recommended to increase the toughness and flexibility of low polar / hydrophobic resins such as those used in structural adhesives and electronic and composite applications.

- Clearstrength® XT152 is a unique toughening solution that does not affect thermomechanical properties (glass transition temperature).

- Loading levels depend on final application and associated technical performance requirements.

Properties

- Physical Form

Technical Details & Test Data

- Unotched Impact Strength in Isobornyl Acrylate Based Methacrylic Formulation

Clearstrength® XT152 provides high toughening effect.

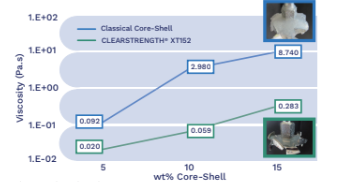

- Viscosity Effect in Isobornyl Acrylate Based Methacrylic UV Formulation

Clearstrength® XT152 has a low impact on viscosity.

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Appearance

- White powder

- Color (SDS)

- White

- Insoluble in (SDS)

- Water

- Odor (SDS)

- Slightly acrylic

- Other Hazards

- Processing may release vapors and/or fumes which cause eye, skin and respiratory tract irritation, The product, in the form supplied, is not anticipated to produce significant adverse human health effects. Contains high molecular weight polymer(s). Effects due to processing releases: Irritating to eyes, respiratory system and skin, Prolonged or repeated exposure may cause: headache, drowsiness, nausea, weakness, (severity of effects depends on extent of exposure) , Handle in accordance with good industrial hygiene and safety practice. (powder) Mechanical irritation effects from dust exposure are possible at ambient temperature. This product may release fume and/or vapor of variable composition depending on processing time and temperature.

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Volatile Content max. 1.0 %(W/W) %(W/W) - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.3 g/cm³ g/cm³ Particle Size max. 200.0 nm nm core shell Particle Size 200.0 µm µm Specific Gravity 1.02 - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Decomposition Temperature (SDS) min. 662.0 °F °F Density (SDS) 1.0 kg/m³ kg/m³ at 20°C Specific Gravity (SDS) 1.0 - at 20°C, water = 1, liquid - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d