Enhanced TDS

Identification & Functionality

- Chemical Family

- Composite Materials Functions

- Plastics & Elastomers Functions

- Product Code

- MITM16502

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Benefits

Improving the mechanical properties in opaque polyester resins like PET and rPET:

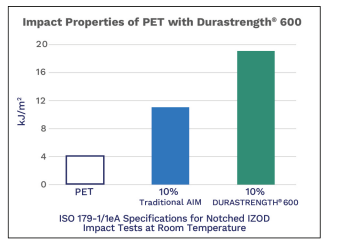

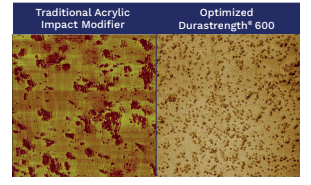

Durastrength® 600 was optimized to give better compatibility with PET and rPET. With this new technology, thanks to the improved dispersion, greater than two times impact strength can be achieved when compared to traditional acrylic impact modifier (AIM). Compared to neat PET, with the addition of Durastrength® 600 greater than four times impact strength can be achieved.

Atomic Force Microscopy (AFM) of PET with 10% AIM Additive

Incorporation of more PET or rPET in PC alloys:

Thanks to its optimized compatibility to polyester, Durastrength® 600, at low dosage, allows greater processability and flexibility of using higher amount of PET or rPET in PC alloys.

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Markets

- Applications

- Usage Information

- Durastrength® 600 impact modifier is recommended for use in typical engineering applications such as electronics, home appliance, packaging, composites and automotive applications.

- Durastrength® 600 was developed to increase the usage of PET and/or rPET in engineering resin blend applications where excellent impact strength and weatherability are required.

- Durastrength® 600 has optimized compatibility to provide maximum impact strength in pure PET and/or rPET resin. Prospective clients should evaluate Durastrength® 600 impact modifier in their own laboratories to establish optimum conditions for use in their process and applications.

Properties

- Physical Form

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Appearance

- White powder

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Volatile Content max. 1.0 % % - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.4 g/cm³ g/cm³ Specific Gravity 1.02 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d