Enhanced TDS

Identification & Functionality

- Additives Included

- Blend

- Yes

- Chemical Family

- Plastics & Elastomers Functions

- Polymer Name

- Product Code

- MITM16702

- Single Ingredient

- No

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

Properties

- Physical Form

Technical Details & Test Data

- Test Data

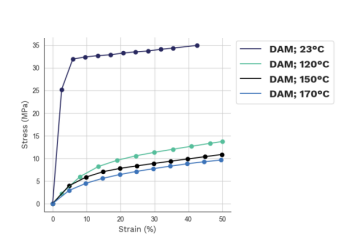

Stress-strain

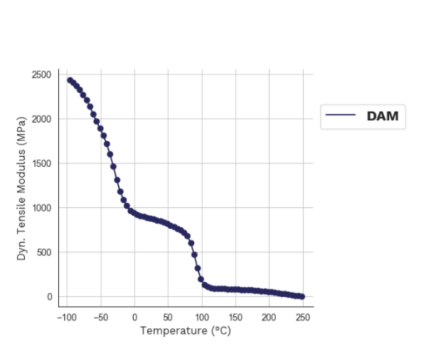

Dynamic Tensile Modulus Temperature

Principal Information

- Group Principal Number

- S000003

- Principal

Storage & Handling

- Storage Information

Two years from the date of delivery, when stored properly (sealed bags, appropriate moisture, UV protection and temperature).

Other

- Color (SDS)

- Black

- Odor (SDS)

- Odorless

- Other Hazards

- Handle in accordance with good industrial hygiene and safety practice. (pellets/granules) This product may release fume and/or vapor of variable composition depending on processing time and temperature.

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Available

- Application Information

Value Units Test Method / Conditions Injection Temperature 90.0-110.0 °C °C - Material Composition

Value Units Test Method / Conditions Carbon Content 48.0 % % ASTM D6866 bio-based - Mechanical Properties

Value Units Test Method / Conditions Flexural Modulus 987.0 MPa MPa ISO 178 at 23°C, conditioned Hardness 66.0 Shore D Shore D ISO 868 at 23ºC,15 s Nominal Strain at Break min. 50.0 % % ISO 527-1 at 23°C, 50 mm/min, conditioned Nominal Strain at Break min. 50.0 % % ISO 527-1 at 23ºC, 50 mm/min,dry Nominal Strain at Break min. 50.0 % % ISO 527-3 at 23°C, 50 mm/min, conditioned Nominal Strain at Break min. 50.0 % % ISO 527-3 at 23ºC, 50 mm/min,dry Strain at Yield 6.6 % % ISO 527-1 at 23°C, 50 mm/min, conditioned Strain at Yield 6.2 % % ISO 527-1 at 23ºC, 50 mm/min,dry Strain at Yield 6.6 % % ISO 527-2 at 23°C, 50 mm/min, conditioned Strain at Yield 6.2 % % ISO 527-2 at 23ºC, 50 mm/min,dry Stress at Yield 32.0 MPa MPa ISO 527-1 at 23°C, 50 mm/min, conditioned Stress at Yield 34.0 MPa MPa ISO 527-1 at 23ºC, 50 mm/min,dry Stress at Yield 32.0 MPa MPa ISO 527-2 at 23°C, 50 mm/min, conditioned Stress at Yield 34.0 MPa MPa ISO 527-2 at 23ºC, 50 mm/min,dry Tensile Modulus 1040.0 MPa MPa ISO 527-1 at 23°C, 1 mm/min, conditioned Tensile Modulus 1050.0 MPa MPa ISO 527-1 at 23°C, 1 mm/min, dry Tensile Modulus 1040.0 MPa MPa ISO 527-2 at 23°C, 1 mm/min, conditioned Tensile Modulus 1050.0 MPa MPa ISO 527-2 at 23°C, 1 mm/min, dry - Physical Properties

Value Units Test Method / Conditions Drying Temperature 100.0-110.0 °C °C Drying Time 4.0-8.0 h h Glass Transition Temperature (Tg) 82.0 °C °C ISO 11357-1 at 10°C/min Glass Transition Temperature (Tg) 82.0 °C °C ISO 11357-2 at 10ºC/min rise Melt Volume-Flow Rate 1.9 cm³/10 min cm³/10 min ISO 1133 at 300ºC, 5 kg Melting Point 270.0-310.0 °C °C Melting Point 260.0 °C °C ISO 11357-3 at 10°C/min Melting Point 260.0 °C °C ISO 11357-1 at 10°C/min Specific Gravity 1.05 - ISO 1183-1 Storage Temperature 140.0 °F °F - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Bulk Density (SDS) 550.0-650.0 kg/m³ kg/m³ Density (SDS) 1.02 g/cm³ g/cm³ Melting Point (SDS) 255.0 °C °C Specific Gravity (SDS) 1.02 - at 20°C, Water - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 2.0 yr yr - Thermal Properties

Value Units Test Method / Conditions Heat Deflection Temperature 82.0 °C °C ISO 75-2 at 0.45 MPa Heat Deflection Temperature 82.0 °C °C ISO 75-1 at 0.45 MPa Heat Deflection Temperature 66.0 °C °C ISO 75-1 at 1.8 MPa Heat Deflection Temperature 66.0 °C °C ISO 75-2 at 1.8 MPa