Enhanced TDS

Identification & Functionality

- Chemical Family

- Country of Origin

- Plastics & Elastomers Functions

- Product Code

- MITM09356

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Physical Form

- Soluble In

Technical Details & Test Data

- Technical Data

Dosing depends on acid end group content and the humidity of the polymer to protect, as well as the expected degree of protection. For Polyester, Polyamide, and thermoplastic Polyurethanes we recommend 1.5 to 2.5 pbw. For millable Urethane rubber we recommend 0.5 to 5 pbw of Stabaxol® I LF.

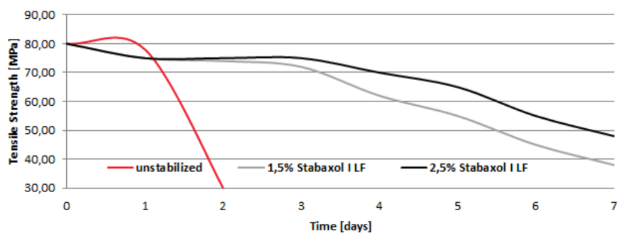

Tensile Strength after Hydrolysis

PET monofilaments in saturated vapor at 120°C

Prior tests should always be carried out to determine the most suitable dosage, however. An addition of 2.5 pbw of Stabaxol® I LF will increase the lifespan of PET about four times. Usually Stabaxol® I LF may be dosed separately. It can be incorporated with all units of machinery suitable for processing Polyester or Polyamide while allowing for a proper additive dispersion. It is advisable to extrude with a twin screw extruder providing an L/D ratio of > 38. Please note that an extruder's feeding zone has to be kept heated in order to prevent material buildup in the feeding zone.

Packaging & Availability

Principal Information

- Group Principal Number

- S000008

- Principal

Storage & Handling

- Storage Conditions

Stabaxol® I LF can be stored for 24 month under cool (below 35 °C / 95 °F) and dry conditions.

Other

- Appearance

- Slightly yellowish crystallized melt

- Appearance (SDS)

- Crystalline

- Color (SDS)

- Light yellow

- Flammable Nature (SDS)

- Sustains combustion

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Slight

- Other Hazards

- None known

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Carbodiimide Content min. 10.0 % % - Physical Properties

Value Units Test Method / Conditions Density 0.97 g/cm³ g/cm³ at 20°C Density 0.95 g/cm³ g/cm³ at 50°C Melting Point 45.0-52.0 °C °C Viscosity 16.0-24.0 mPa.s mPa.s at 50°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Bulk Density (SDS) 600.0-700.0 kg/m³ kg/m³ at 20°C Decomposition Temperature (SDS) min. 240.0 °C °C Density (SDS) 0.95 g/cm³ g/cm³ at 50°C Flash Point (SDS) 194.0 °C °C Open Cup Ignition Temperature (SDS) 806.0 °F °F Melting Point (SDS) 40.0-45.0 °C °C Self Ignition Temperature (SDS) min. 430.0 °C °C - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 24.0 mo mo