Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Chemical Name

- Country of Origin

- Function

- Crosslinking Agent

- Industrial Additives Functions

- Product Code

- MITM02852

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Application Area

- Industrial Additives End Use

- Markets

- Applications

- Product Applications

- Insulation

- Pour-in-Place Insulation

- Portable Coolers

- Rail Boxcars

Properties

- Physical Form

- Soluble In

- Key Properties

Reactivity Profile at 70 °C

Cream 26 Gel 142 Free Rise 192 Tack Free 201

Technical Details & Test Data

- Technical Data

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S001809

- Principal

Storage & Handling

- Storage Conditions

- CARPOL® SP-477 will absorb water if the product container is not secured properly.

- This may affect reactivity, appearance, and performance.

- Therefore, it is advised that all receptacles containing this material be tightly fastened and stored in a dry place.

Other

- Appearance

- Free and clear

- Item Number

- Odor (SDS)

- Slight sweet odor

- Other Hazards

- None identified

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Curing Time 201.0 m m at 70°C, reactivity profile - Chemical Properties

Value Units Test Method / Conditions Amine Value 1.0 mg KOH/g mg KOH/g Hydroxyl Value 470.0 mg KOH/g mg KOH/g pH 0.1 - 10 parts IPA: 6 parts H₂O - Material Composition

Value Units Test Method / Conditions Potassium Content max. 20.0 ppm ppm - Mechanical Properties

Value Units Test Method / Conditions Compressive Strength 28.0 psi psi parallel Compressive Strength 24.0 psi psi PET, at 1/3 standard depth with 1% titanium dioxide (ABS 4% titanium dioxide, PS 2% titanium dioxide) - Optical Properties

Value Units Test Method / Conditions Color Scale max. 7.0 Gardner Gardner Gardner Color Scale - Physical Properties

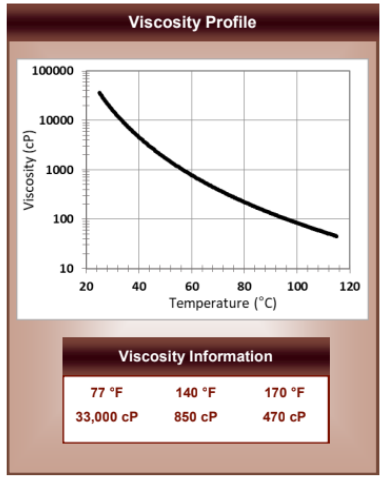

Value Units Test Method / Conditions Change in Low Temperature Age -0.5 % % at -20°F, 28 days, as change Density 9.42 lb/gal lb/gal at 25°C Density 2.2 lb/in³ lb/in³ Density 192.0 lb/in³ lb/in³ at 70°C, reactivity profile Moisture Content max. 0.1 % % Relative Humidity 3.8 % % at 158°F, 90% R.H, 28 days, as change Viscosity 33000.0 cPs cPs at 25°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Flash Point (SDS) min. 200.0 °F °F Specific Gravity (SDS) 1.13 - Water = 1 pH (SDS) 7.0 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d