Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Composite Materials Functions

- Country of Origin

- Function

- Impact Modifier

- Plastics & Elastomers Functions

- Product Code

- MITM10319

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Benefits

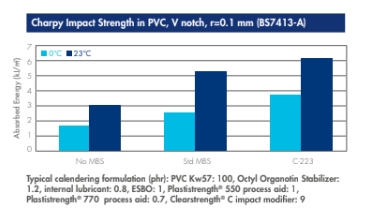

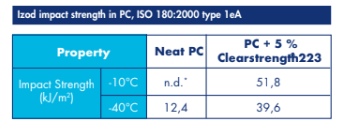

Impact Strength:

Due to its high rubber content, Clearstrength® 223 impact modifier offers high impact efficiency at room and low temperature, allowing dosage optimization and cost saving in formulation:

Processability:

Clearstrength® 223 impact modifier specific structure makes it suitable to withstand severe processing conditions such as hightemperature extrusion and injection with minimal effect on heat stability and mechanical properties.

Easy Dispersion:

Clearstrength® 223 impoct modifier is easily dispersed in vinyl or polycarbonate based formulations assuring more consistent impact resistance and other physical properties.

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Product Uses

- Clearstrength® 223 impact modifier is recommended for use in high quality technical PVC films and edge-bands, CPVC pipes and fittings and all applications requiring very high impact retention, especially at low temperatures It is also recommended for use in automotive applications, electrical and electronic components, household appliances and al PC & alloys parts where ease of processing, good ow temperature impact and good balance of physical properties are important.

- Clearstrength® 223 impact modifier is commonly used in PVC formulations for food contact or drinking water conduction.

- Recommended loading levels depend on impact requirement ; typical levels range from 2 to 20%

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Appearance

- White powder

- Color (SDS)

- White

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Slightly acrylic

- Other Hazards

- Processing may release vapors and/or fumes which cause eye, skin and respiratory tract irritation, The product, in the form supplied, is not anticipated to produce significant adverse human health effects. Contains high molecular weight polymer(s). Effects due to processing releases: Irritating to eyes, respiratory system and skin, Prolonged or repeated exposure may cause: headache, drowsiness, nausea, weakness, (severity of effects depends on extent of exposure), Handle in accordance with good industrial hygiene and safety practice. (powder) Mechanical irritation effects from dust exposure are possible at ambient temperature. This product may release fume and/or vapor of variable composition depending on processing time and temperature.

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) 2.0-20.0 % % - Material Composition

Value Units Test Method / Conditions Volatile Content max. 1.0 % % - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.39 g/cm³ g/cm³ Sieve Fractionation (Retained) max. 2.0 % % +18 mesh Specific Gravity 1.02 - Storage Temperature max. 104.0 °F °F - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) 878.0 °F °F Bulk Density (SDS) 300.0-400.0 kg/m³ kg/m³ Decomposition Temperature (SDS) min. 482.0 °F °F - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 730.0 d d