Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Carrier

- Chemical Family

- Function

- Crosslinking Agent

- Product Code

- MITM00241

- Single Ingredient

- Yes

- Technologies

- Product Families

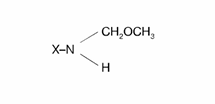

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

Applications & Uses

- Compatible Polymers & Resins

- Product Applications

In solvent borne systems:

- CYMEL® 323 Resin is a methylated melamine-formalde- hyde crosslinking agent with a medium to high degree of alkylation, a low methylol content and medium to high imino functionality.

- CYMEL® 323 Resin is a very effective crosslinking agent for backbone polymers containing hydroxyl, amide and, to some extent, carboxyl functional groups, such as epoxy, alkyd/polyester or acrylic resins.

- CYMEL® 323 Resin is suitable for a wide range of industrial stoving systems, providing exceptional fast cure response.

- The baking volatiles from CYMEL® 323 Resin contain very low levels of formaldehyde even though the tendency to self condensation takes prefer- ence over the crosslinking reaction. Compared to other high imino, methylated crosslinking agents, CYMEL® 323 Resin shows improved film hardness, solvent and humid- ity resistance.

In water borne systems:

- CYMEL® 323 Resin is soluble in water, and has an excel- lent compatibility with water soluble backbone polymers.

- The carboxyl functionality of anionic backbone polymers is sufficiently acidic to catalyze the reaction at relatively low temperature curing schedules.

- In all water bomne sys- tems where speed of cure is very important, CYMEL® 323 Resin is strongly recommended.

Catalysis:

- CYMEL® 323 Resin requires weak acid catalysts for cure at normal baking schedules.

- The acidity of the primary film former is usually sufficient to initiate the curing process.

- The cure can be additionally catalyzed by weak organic or inorganic acids such as CYCAT 296-9 catalyst, which has proved to be a very effective catalyst for these systems.

Properties

- Physical Form

- Soluble In

- Stability Data

- Formulated systems containing CYMEL® 323 have to be stabilized with primary alcohols, amines or with a combination of these.

- For water borne systems a pH value between 7.0-8.5 should be maintained to achieve stability.

Technical Details & Test Data

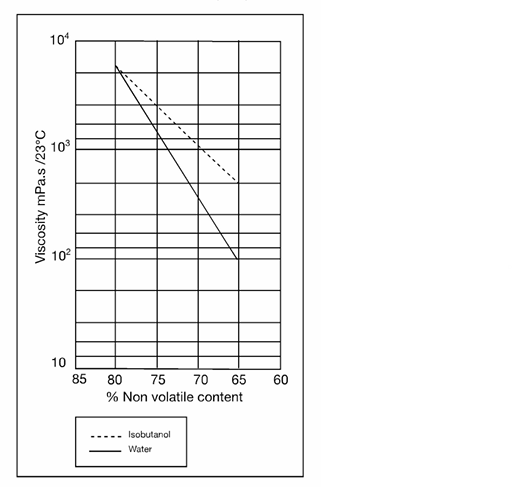

- Viscosity vs Percentage Non Volatile Content Graph

Typical Thin-down Curve in Isobutanol/water (at 23°C):

Packaging & Availability

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage Conditions

- Storage stability at ambient temperatures is minimum one year after delivery. Avoid direct sunshine.

Other

- Appearance

- Clear liquid

- Appearance (SDS)

- Viscous liquid isobutanol

- Color (SDS)

- Water

- IATA/ICAO Proper Shipping Name

- Resin solution

- IATA/ICAO UN Number

- UN1866

- IMO/IMDG Proper Shipping Name

- Resin solution

- IMO/IMDG UN Number

- UN1866

- Item Number

- Other Hazards

- Not applicable

- TDG Canada Proper Shipping Name

- Resin solution

- TDG Canada UN Number

- UN1866

- USA/DOT Proper Shipping Name

- Resin solution

- USA/DOT UN Number

- UN1866

- Optical Properties

Value Units Test Method / Conditions Color Scale max. 70.0 APHA APHA Color Scale max. 70.0 Gardner Gardner ISO 6271 - Chemical Properties

Value Units Test Method / Conditions Free Formaldehyde Content 0.3 % % ISO 9020 pH 7.0-8.5 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 1.0 yr yr - Physical Properties

Value Units Test Method / Conditions Density 1120.0 kg/m³ kg/m³ ISO 2811 at 23°C Flash Point 33.0 °C °C ISO 3679 Viscosity 2500.0-7500.0 mPa.s mPa.s at 23°C Viscosity 2500.0-7500.0 mPa.s mPa.s Viscosity 2500.0-7500.0 mPa.s mPa.s ISO 3219 at 23°C - Material Composition

Value Units Test Method / Conditions Non-Volatile Content 78.0-82.0 % % at 45°C, foil, 45 min - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 108.0 °C °C Density (SDS) 1.134 g/cm³ g/cm³ Evaporation Rate (SDS) 0.62 % % Butyl acetate = 1 Flammable Limits (SDS) 1.2-10.9 %(V/V) %(V/V) Flash Point (SDS) 33.0 °C °C Pensky-Martens Closed Cup (PMCC) Relative Vapor Density (SDS) 2.55 - Air = 1 Vapor Pressure (SDS) 10.0 mm Hg mm Hg At 22°C Volatile Content (SDS) 20.0 %(W/W) %(W/W) pH (SDS) 6.0-9.0 -