Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Plastics & Elastomers Functions

- Product Code

- MITM09355

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Adhesive & Sealant End Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Physical Form

- Soluble In

Technical Details & Test Data

- Technical Data

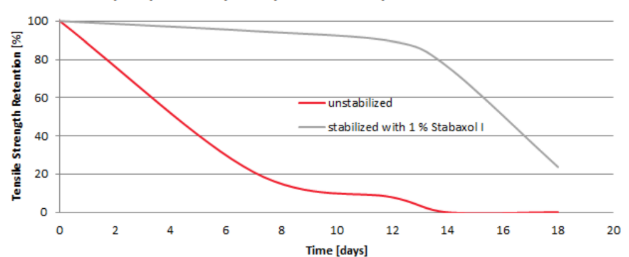

Stabaxol® I is normally being dissolved in the polyester polyol; alternatively, it may be added to the pre-polymer (only with terminal OH-groups). An addition of 1 part by weight Stabaxol® I to 100 parts by weight polyester polyol increases the resistance to hydrolysis up to 7 times. This data was established by tests conducted at 80 % relative humidity. Stabaxol® I gives the best results when added in a concentration of up to 2 parts by weight to otherwise unprotected polyester polyurethane elastomers.

Hydrolytic Stability of Polyester based Polyurethane Elastomers

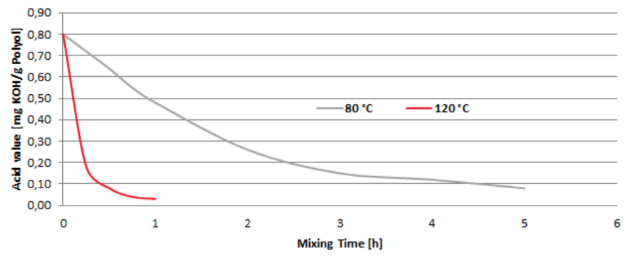

For adhesives we recommend to add 1-2 parts by weight Stabaxol® I to 100 parts by weight adhesive. Prior tests should always be carried out to determine the most suitable dosage, however. To be most effective, Stabaxol® I should be added to the polyester polyol during the warming-up period, starting at a minimum temperature of 50 °C (122 °F), to a maximum temperature of 120 °C (248 °F). As Stabaxol® I does not disperse readily (it may float undissolved on the surface), it should be stirred intensively. The necessary time and temperature to complete the reaction is shown in the graph below.

Acid Reduction with 1% Stabaxol I in Polyester Polyol

Stabaxol® I may slightly accelerate the crosslinking reaction (polyester polyol/iscoyanate). This can be counteracted by adding a very small amount of an organic acid (e.g. citric acid).

Packaging & Availability

Principal Information

- Group Principal Number

- S000008

- Principal

Storage & Handling

- Storage Conditions

Stabaxol® I can be stored for at least 24 month under cool (below 35 °C / 95 °F) and dry conditions.

Other

- Appearance

- Slightly yellowish crystallized melt

- Appearance (SDS)

- Crystalline solid

- Color (SDS)

- Light yellow

- Flammable Nature (SDS)

- Sustains combustion

- Item Number

- Odor (SDS)

- Slight characteristic

- Other Hazards

- None known

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Carbodiimide Content min. 10.0 % % - Physical Properties

Value Units Test Method / Conditions Density 0.97 g/cm³ g/cm³ at 20°C Density 0.95 g/cm³ g/cm³ at 50°C Melting Point 45.0-52.0 °C °C Viscosity 16.0-24.0 mPa.s mPa.s at 50°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 294.0 °C °C at 1,013 hPa, thermal decomposition Decomposition Temperature (SDS) min. 240.0 °C °C Density (SDS) 0.97 g/cm³ g/cm³ at 20°C Flash Point (SDS) 194.0 °C °C DIN ISO 2592 Flash Point (SDS) 194.0 °C °C Open Cup Ignition Temperature (SDS) 430.0 °C °C Melting Point (SDS) 50.97 °C °C at 1 mmHg, room temperature Solubility In Water (SDS) max. 5.0 g/L g/L OECD 105 at 20°C Vapor Pressure (SDS) max. 1.0 hPa hPa at 20°C Vapor Pressure (SDS) 6.0 hPa hPa at 210°C - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 24.0 mo mo