Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Plastics & Elastomers Functions

- Product Code

- MITM09359

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

Properties

- Physical Form

- Soluble In

Technical Details & Test Data

- Technical Data

It is recommended to add 1.0 - 4.0 p.b.w. Stabaxol® P 200 on 100 p.b.w. of the polyol component. However, prior tests should always be carried out to determine the most suitable dosage.

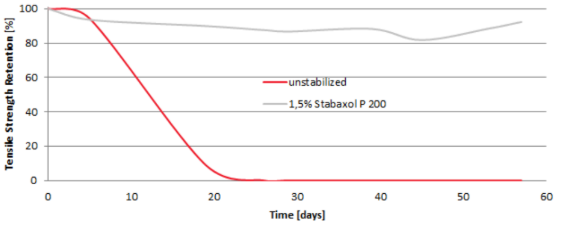

Hydrolytic Stability of Polyester based TPU-Elastomers

For processing, Stabaxol® P 200 is normally dissolved in the polyester polyol; alternatively, it may be added to the pre-polymers (only with terminal OH groups) or may be added directly into the mixing head in case of cast systems.

Packaging & Availability

Principal Information

- Group Principal Number

- S000008

- Principal

Storage & Handling

- Storage Conditions

Stabaxol® P 200 can be kept for 24 months under cool and dry conditions.

Other

- Appearance

- Bright yellow viscous liquid

- Appearance (SDS)

- Viscous liquid

- Color (SDS)

- Yellow

- Item Number

- Odor (SDS)

- Slight

- Other Hazards

- None known

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) 1.0-4.0 - - Chemical Properties

Value Units Test Method / Conditions Hydroxyl Value 13.0 mg KOH/g mg KOH/g - Material Composition

Value Units Test Method / Conditions Carbodiimide Content min. 6.0 % % - Physical Properties

Value Units Test Method / Conditions Density 1.1 g/cm³ g/cm³ At 25°C Freeze Point max. 5.0 °C °C Viscosity 1.0-6.0 - at 23°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Decomposition Temperature (SDS) min. 250.0 °C °C Density (SDS) 1.1 g/cm³ g/cm³ DIN 51757 at 25°C Flash Point (SDS) 230.0 °C °C Regulation (EC) No. 440/2008, Annex, A.9 Ignition Temperature (SDS) 380.0 °C °C Log Partition Coefficient (Log Pow) (SDS) 0.4-2.9 - n-octanol/water Melting Point (SDS) max. 5.0 °C °C Relative Density (SDS) min. 1.0 - at 25°C Solubility In Water (SDS) min. 2000.0 g/L g/L OECD 105 Vapor Pressure (SDS) 3.0 - At 20°C Viscosity (SDS) 1000.0-6000.0 - at 25°C pH (SDS) 7.0 - at 25°C - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 24.0 -