Enhanced TDS

Identification & Functionality

- Base Chemicals Functions

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Chemical Name

- Country of Origin

- Fluids & Lubricants Functions

- Function

- Filler, Intermediate

- Industrial Additives Functions

- Plastics & Elastomers Functions

- Product Code

- MITM12971

- Single Ingredient

- Yes

- Synonyms

- Elbor

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Fluids & Lubricants Features

- Industrial Additives Features

- Labeling Claims

- Materials Features

- Product Benefits

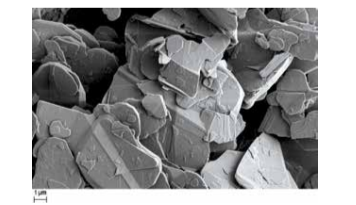

3M™ Boron Nitride is a versatile ceramic material offering thermal conductivity, temperature stability, chemical resistance, high reflectivity, lightweighting and electrical insulation. The structure of layered hexagonal plates provides outstanding lubricating properties and is non-abrasive to tooling.

- Product Features

- Increases thermal conductivity while maintaining electrical insulation.

- Compatible with standard polymers.

- Low density.

- Product Benefits

3M™ Technical Ceramics offers a family of boron nitride cooling filler materials:

- 3M™ Boron Nitride Cooling Filler Platelets 009: Powders of highly crystalline single platelets

- 3M™ Boron Nitride Cooling Filler Agglomerates* (experimental product): Soft, randomly oriented aggregated platelets

- 3M™ Boron Nitride Cooling Filler Flakes (experimental product): Hard, oriented aggregated platelets

Applications & Uses

- Fluids & Lubricants End Use

- Fluids & Lubricants Type

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Processing Information

Factors such as melt temperature, compounding technique, injection rate and more can have a significant effect on the thermal and electrical insulative properties of parts made with boron nitride cooling fillers.

Properties

- Physical Form

Regulatory & Compliance

- Quality Standards

Technical Details & Test Data

- Technical Data

3M™ Boron Nitride Cooling Filler Platelets 009

Optimal all-purpose grades for pads and injection molded parts.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S002409

- Principal

Other

- Color (SDS)

- White

- Item Number

- Odor (SDS)

- Odorless

- Other Hazards

- May cause thermal burns

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions Active Oxygen Content max. 0.5 % % - Material Composition

Value Units Test Method / Conditions Boron Nitride Content min. 98.5 % % Boron Trioxide Content max. 0.1 % % Carbon Content max. 0.06 % % - Physical Properties

Value Units Test Method / Conditions Bulk Density max. 0.22 g/cm³ g/cm³ ASTM B329 Bulk Density max. 0.22 g/cm³ g/cm³ DIN Method Bulk Density max. 0.22 g/cm³ g/cm³ ISO 23145-2 Bulk Density max. 0.22 g/cm³ g/cm³ ISO 3923-2 Bulk Density max. 0.22 g/cm³ g/cm³ Scott Volumeter Particle Size 6.0-12.0 µm µm Laser Light Scattering 0.1 bar, d(0.5), mastersizer 2000, dry Particle Size 2.0-3.5 µm µm Laser Light Scattering d 0.1, mastersizer 2000, dry, 0.1 bar Particle Size 14.0-32.0 µm µm Laser Light Scattering d 0.97, mastersizer 2000, dry, 0.1 bar Specific Surface Area max. 5.5 m²/g m²/g - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Bulk Density (SDS) 50.0-550.0 - Decomposition Temperature (SDS) 2730.0 °C °C Density (SDS) 2.25 g/cm³ g/cm³ at 20°C Solubility In Water (SDS) max. 0.162 mg/L mg/L - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 -