Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Composite Materials Functions

- Country of Origin

- Function

- Toughness Modifier, Toughener

- Plastics & Elastomers Functions

- Product Code

- MITM10978

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Key Features

- Methylmethacrylate-Butadiene-Styrene (MBS) core shell

- Easily dispersible powder

- Tailored for thermosetting resins

- Optimized for (meth) acrylic, epoxy and polyesters

- Matching high technical requirements

Applications & Uses

- Compatible Polymers & Resins

- Dispersion Information

- Clearstrength® XT100 powder can be dispersed with low to medium shear conditions in acrylic and polyesters at room temperature.

- Medium shear conditions in temperature can be used for dispersion in epoxy resins.

- Product Uses

- Clearstrength® XT100 is particularly recommended to increase the toughness of thermoset systems such as structural adhesives (e.g. methacrylates, epoxies, etc.) and composites.

- Recommended loading levels depend on fi nal application and associated technical performance requirements.

- Clearstrength® XT100 can be advantageously used to replace standard core shell modifi er powders but also liquid masterbatches of pre-dispersed core shell particles.

Properties

- Physical Form

Technical Details & Test Data

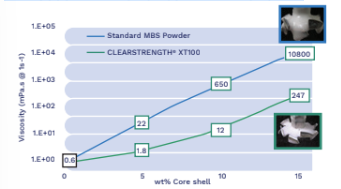

- Viscosity effect of Clearstrength in MMA monomer

- Benefits in Epoxy

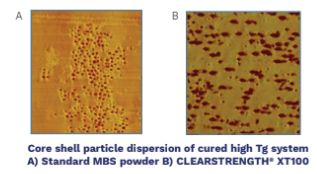

- In high Tg epoxy system

K1C(MPa√m)

G1C(J/m²)

Neat 0.6 88 Standard MBS Powder (5wt%) 1.1 380 CLEARSTRENGTH® XT100 (5wt%) 1.4 490 Clearstrength® XT100 yields superior toughness and shear adhesion strength in high Tg epoxy (Tg>200°C) than Standard MBS powder.

Enhancing compatibility reaching dispersion at the individual core shell in most epoxy systems.

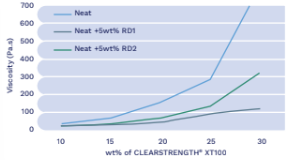

- In DGEBA/DDA combined with reactive diluent

Epoxy System DGEBA/DDA

K1C (MPa√m) G1C (J/m²) Tg (°C) Neat 0.68 0.53 136 10wt% XT 100 1.1 2.1 135 10wt% XT 100 with 5wt% RD1 1.5 3 130 10wt% XT 100 with 5wt% RD2 1.3 2.5 133

Classical Reactive Diluents like 1,6-hexanediol diglycidyl ether (RD1) or 1,4-cyclohexanedi-methanol diglycidyl ether (RD2) are excellent solvent for Clearstrength® XT100 powder. They allow a great decrease of the viscosity and a new compromise of toughness versus Tg is achievable.

- Technical Data

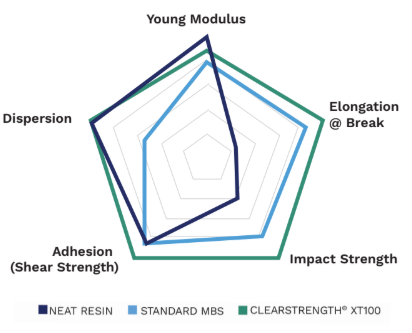

Methacrylate Structural Adhesive Formulation (15wt%)

Clearstrength® XT100 into a methacrylate structural adhesive formulation

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000003

- Principal

Other

- Appearance

- White powder

- Color (SDS)

- White

- Item Number

- Odor (SDS)

- Slightly acrylic

- Other Hazards

- Processing may release vapors and/or fumes that irritate the eyes, skin, and respiratory tract, The product, in this form, is not considered to have significant harmful effects on health. Contains one or more high molecular weight polymers. Effects attributable to processing emissions: Irritant to eyes, respiratory system, and skin. Possible cross-sensitization with other acrylates and methacrylates. Prolonged or repeated exposure may cause: Headaches, drowsiness, nausea, weakness, (the severity of effects varies with exposure), Follow the usual precautionary measures applicable when handling chemicals. (powder) A mechanical irritation effect due to exposure is possible at room temperature. This product may emit smoke and vapors of various compositions depending on temperature and processing time.

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Volatile Content max. 1.0 %(W/W) %(W/W) - Physical Properties

Value Units Test Method / Conditions Bulk Density 0.3 g/cm³ g/cm³ Particle Size max. 200.0 nm nm core shell Specific Gravity 1.02 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 730.0 d d