Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Industrial Additives Functions

- Product Code

- MITM14934

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Key Features

- 30% active water-soluble anionic fluorosurfactant effective at low end use concentrations

- Powerful wetting and leveling performance for smoother, defect-free coatings

- Does not impart color, or change the optical properties of a coating, beyond potential gloss or DOI (distinctness of image) improvement from better reflectance

- Containing a Low Vapor Pressure solvent, partially replaces coalescent solvents for VOC formulation reductions

- Readily dilutes in water, or water/alcohol/glycol mixtures with excellent shelf stability

- Stable in highly acidic or basic environments, and in hard water without chelation

- Exceptional stability and functionality in severe thermal and chemical environments

Applications & Uses

- Coating End Applications

- Compatible Substrates & Surfaces

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Ink & Toner End Applications

- Markets

- Applications

- Product Applications

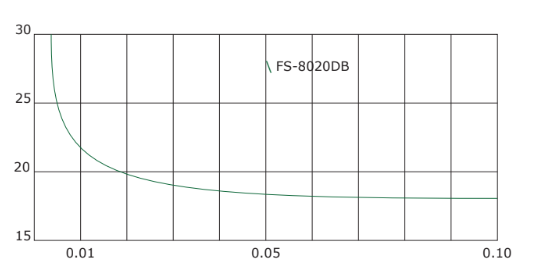

Recommended use concentrations vary for Thetawet™ FS-8020DB with application, but in general, the surface tension of aqueous solutions and emulsions can be reduced to 19-20 dynes/cm with the addition of as little as 0.01 to 0.05% as supplied.

- Product Applications

- Wetting agent

- Floor finishes and sealers

- Automotive Finishes and Top Coats

- Lacquers and Polishes

- Adhesives

- Industrial and Architectural Paints & Coatings

- Additive for fiber finishes for improved finish uniformity

Properties

Technical Details & Test Data

- Technical Information

- Thetawet™ FS-8020DB is a 30% active water soluble, moderate foaming anionic fluorosurfactant.

- Containing a low vapor pressure solvent, Thetawet™ FS-8020DB ideal for use in low VOC applications.

- Thetawet™ FS-8020DB is an excellent choice for wetting difficult to wet surfaces such as plastics, oily substrates, waxy surfaces, and for reduction in coating surface defects, and enhanced gloss development for smoother, more even films in finishes and polishes.

- Thetawet™ FS-8020DB provides far greater surface tension reduction than can be achieved with either hydrocarbon or silicone-based surfactants, and is stable even in highly acidic or basic environments.

- When used in conjunction with “conventional” hydrocarbon wetting agents, it is possible to achieve a system that not only dramatically reduces surface tension, but also lowers interfacial tension resulting in a liquid that easily wets and spreads on otherwise hare to wet surfaces.

- Technical Information

- Through extensive product development, application research and manufacturing optimization, Thetawet™ FS-series short chain fluorosurfactants deliver performance on-par with long- chain alternatives.

- Often used along with traditional and specialty surfactants,Thetawet™ FS-series short-chain fluorosurfactants deliver maximum performance not achievable with traditional and specialty alkyl, acetylenic diol and silicone surfactants alone.

- Thetawet™ FS-series short-chain fluorosurfactants are exceptional wetting agents efficient at low end-use concentrations, typically in the 10-100 ppm range.

- Very low end-use concentrations allow for economical use and often eliminate re-wet properties characteristic of the higher end use concentrations required with traditional and specialty surfactants.

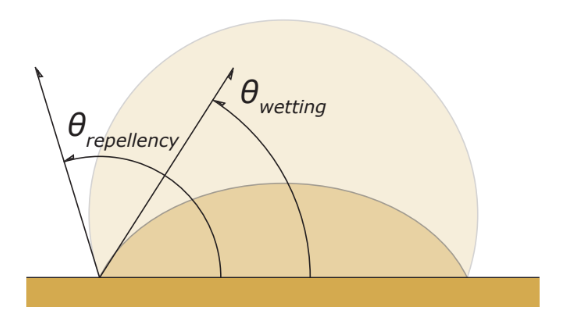

- Physical Scientists assigned the Greek Letter Theta θ to represent the angle formed by a liquid at the three phase boundary where a solid, liquid, and gas intersect. It is also known as the contact angle.

- The measurement of Theta is the means by which we can quantify both how well a liquid can wet out a surface, or by contrast, how well a surface can resist being wetted.

- The manipulation and control of Theta is critical in the design of effective oil, water, and stain repellents, and the reduction of surface tension necessary to make improved coatings and cleaning products.

- As illustrated below, a decreasing θrepresents increasing wetting and adhesiveness, and an increasing θrepresents increasing repellency.

It is only fitting that ICT chose Theta θ to represent these new and exciting products.

- Thetawet™ FS-8020DB is an excellent choice for wetting difficult to wet low energy surfaces such as plastics, oily substrates, waxy surfaces, and silicone and fluoropolymer treated fabrics.

- The ability of FS-8020DB to lower the aqueous surface tension of liquids, allows those liquids to wet low energy surfaces.

- By contrast, typical alkyl surfactants, at any concentration, will only lower aqueous surface tension to about 30 dynes/cm, meaning that a typical alkyl surfactant solution will not wet a 25 dynes/cm surface, resulting in lack of coverage, incomplete leveling or inadequate cleaning performance.

Aqueous Surface Tension, duNoüy ring, Wt.% actives, dynes/cm at 25°C

- Demonstrated above, the surface tension of aqueous solutions and emulsions can be reduced to 19 - 20 dynes/cm with as little as 0.01-0.05% Thetawet™ FS-8020DB.

- This low surface tension results in better wetting, spreading, and penetration which translates into improved film uniformity, enhanced adhesion, reduced pinholes and craters for coatings, improved spreading for reduced water spotting, and smoother and more even films for finishes and polishes.

- It also translates into better wetting and penetration of cleaning solutions which makes them more effective.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S002669

- Principal

Other

- Appearance

- Clear to slightly hazy colorless to pale yellow liquid

- Appearance (SDS)

- Clear to slightly hazy liquid. Separates into two phases upon standing.

- Color (SDS)

- Colorless to pale yellow

- Explosive Nature (SDS)

- Not explosive

- Item Number

- Odor

- Mild

- Odor (SDS)

- Mild

- Other Hazards

- Non Hazardous

- Oxidizing Properties (SDS)

- Not oxidising

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) 0.01-0.05 % % - Chemical Properties

Value Units Test Method / Conditions pH 5.0-6.0 - 5% aqueous solution - Physical Properties

Value Units Test Method / Conditions Density 1.12-1.18 g/mL g/mL at 25°C Flash Point min. 200.0 °F °F Tag Closed cup Storage Temperature max. 122.0 °F °F - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (SDS) 1.12-1.18 g/mL g/mL Evaporation Rate (SDS) 1.0 % % Water = 1 Flash Point (SDS) min. 93.3 °C °C pH (SDS) 4.5-6.5 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 12.0 mo mo