Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Chemical Name

- Country of Origin

- Product Code

- MITM00577

- Single Ingredient

- Yes

- Synonyms

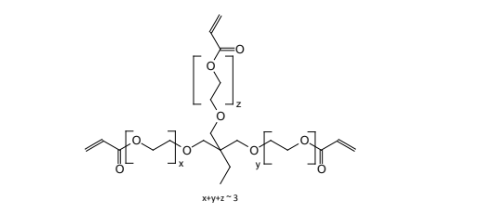

- Ethoxylated trihydroxymethylpropane triacrylate, Ethoxylated trimethylolpropane tripropenoate, Ethoxylated trimethylpropane triacrylate, Ethylene oxide-trimethylolpropane copolymer triacrylate, Oxyethylated trimethylolpropane triacrylate, Poly(ethoxylated trimethylolpropane triacrylate), Polyethylene glycol trimethylolpropane ether triacrylate, Polyoxyethylated trimethylolpropane triacrylate, Trimethylolpropane ethoxylate triacrylate, Trimethylolpropane polyethylene glycol ether (1:3) triacrylate, Trimethylolpropane polyethylene glycol ether triacrylate, Trimethylolpropane tris(polyethylene glycol ether) triacrylate

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Product Benefits

TMPEOTA is characterized by:

• Low viscosity

• Low vapor pressure

• High acrylate functionality

UV/EB curable formulated products containing TMPEOTA are characterized by:

• Rapid cure response

• Good flexibility

• Improved adhesion

Applications & Uses

- Coating End Applications

- Compatible Polymers & Resins

- Cure Method

- Industrial Additives End Use

- Ink & Toner End Applications

- Markets

- Applications

- Product Applications

- TMPEOTA is a reactive diluent compatible with a wide range of acrylated resins used in UV/EB curing applications.

- Hardness, abrasion resistance, and high gloss properties make TMPEOTA popular for overprint varnishes, inks, coatings and electronic applications such as photoresists.

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage Conditions

- Care should be taken not to expose the product to high temperature conditions, direct sunlight, ignition sources, oxidizing agents, alkalis or acids.

- This might cause uncontrollable polymerization of the product with the generation of heat.

- Storage and handling should be in stainless steel, amber glass, amber polyethylene or baked phenolic lined containers.

- Procedures that remove or displace oxygen from the material should be avoided.

- Do not store this material under an oxygen free atmosphere.

- Dry air is recommended to displace material removed from the container.

- Wash thoroughly after handling.

- Keep container tightly closed.

- Use with adequate ventilation.

Other

- Appearance

- Clear liquid

- Appearance (SDS)

- Clear liquid

- Color (SDS)

- Clear colorless to slightly yellow

- Item Number

- Odor (SDS)

- Ester like

- Other Hazards

- Polymerization may occur from excessive heat, contamination or exposure to direct sunlight .

- Oxidizing Properties (SDS)

- None

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions Acid Value max. 0.4 mg KOH/g mg KOH/g - Material Composition

Value Units Test Method / Conditions Solvent Content max. 0.09 %(W/W) %(W/W) residue - Optical Properties

Value Units Test Method / Conditions Color Scale max. 60.0 Pt-Co Pt-Co - Physical Properties

Value Units Test Method / Conditions Density 1.1 g/mL g/mL at 25°C Flash Point min. 100.0 °C °C SetaFlash Closed Cup Storage Temperature 39.0-104.0 °F °F Viscosity 60.0-80.0 cPs cPs at 25°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) min. 200.0 °C °C Boiling Point (SDS) min. 391.0 °C °C Log Partition Coefficient (Log Pow) (SDS) 2.89 - OECD 107 at 23°C Melting Point (SDS) max. -20.0 °C °C Solubility In Water (SDS) 880.0 mg/L mg/L Specific Gravity (SDS) 1.107 - at 20°C Vapor Pressure (SDS) 32.0 Pa Pa at 20°C Viscosity (SDS) 80.0 mPa.s mPa.s at 20°C, low viscous liquid Volatile Content (SDS) max. 0.3 %(W/W) %(W/W) - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d