Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Chemical Name

- Country of Origin

- Fluids & Lubricants Functions

- Function

- Filler

- Plastics & Elastomers Functions

- Product Code

- MITM09978

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Fluids & Lubricants Features

- Labeling Claims

- Materials Features

- Product Features

- Increases thermal conductivity while maintaining electrical insulation.

- Compatible with standard polymers.

- Low density.

Applications & Uses

- Fluids & Lubricants End Use

- Fluids & Lubricants Type

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Product Applications

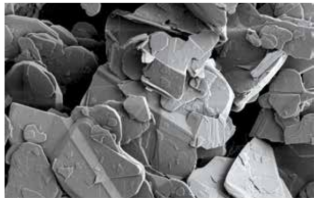

3M™ Boron Nitride Cooling Filler 012 are engineered to improve thermal conductivity in polymers while maintaining or improving electrical insulation. Their unique properties make these additives suitable for many thermoplastic, elastomer and thermoset resins used in a wide variety of electrical and electronic applications– including thermal interface materials (TIM), consumer electronics and automotive applications.

- Processing Information

Factors such as melt temperature, compounding technique, injection rate and more can have a significant effect on the thermal and electrical insulative properties of parts made with boron nitride cooling fillers.

Properties

- Physical Form

Regulatory & Compliance

- Quality Standards

Technical Details & Test Data

- Technical Data

Optimal all-purpose grades for pads and injection molded parts.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S002409

- Principal

Other

- Color (SDS)

- White

- Item Number

- Odor (SDS)

- Odorless

- Other Hazards

- May cause thermal burns

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions Active Oxygen Content max. 0.5 % % - Material Composition

Value Units Test Method / Conditions Boron Nitride Content min. 98.5 % % Boron Trioxide Content max. 0.1 % % Carbon Content max. 0.06 % % - Physical Properties

Value Units Test Method / Conditions Bulk Density max. 0.25 g/cm³ g/cm³ ASTM B329 scott Bulk Density max. 0.25 g/cm³ g/cm³ ISO 3923-2 scott Bulk Density max. 0.25 g/cm³ g/cm³ Scott Volumeter Particle Size 8.0-14.0 µm µm Laser Light Scattering 0.1 bar, d(0.5), mastersizer 2000, dry Particle Size 20.0-40.0 µm µm Laser Light Scattering 0.1 bar, d(0.9), mastersizer 2000, dry Particle Size 2.0-4.5 µm µm Laser Light Scattering d(0.1), mastersizer 2000, dispersion in ethanol Particle Size 2.0-4.5 µm µm Laser Light Scattering d 0.1, mastersizer 2000, dry, 0.1 bar Particle Size 8.0-14.0 µm µm Laser Light Scattering D(0.5) Particle Size 20.0-40.0 µm µm Laser Light Scattering D90 Specific Surface Area max. 5.0 m²/g m²/g - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Bulk Density (SDS) 50.0-550.0 - Decomposition Temperature (SDS) 2730.0 °C °C Density (SDS) 2.25 g/cm³ g/cm³ at 20°C Solubility In Water (SDS) max. 0.162 mg/L mg/L - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 2190.0 -